Philosopher, computer scientist, and AI developer Joscha Bach explains his interest in animist ideas about spirits governing reality and how they exist as’software patterns’.

Get the latest international news and world events from around the world.

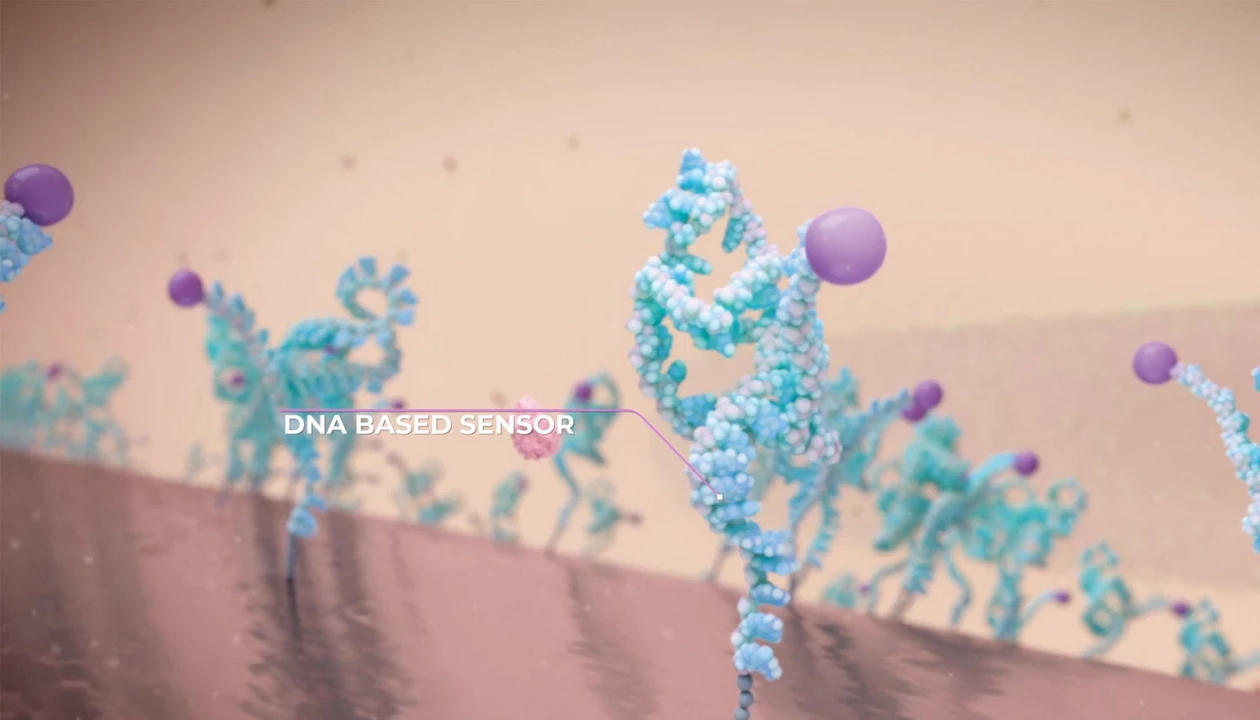

Drug dose monitoring with a DNA-based microneedle sensor

A wearable DNA-based sensor similar to a continuous glucose monitor can accurately and safely detect vancomycin concentrations in the body.

Aptamer-coated microneedle patch can detect amounts of the antibiotic vancomycin in real time for at least 12 hours by Helen Albert, special to C&EN.

The BZR1-interacting WD repeat protein participates in brassinosteroid-dependent growth and stress response in tomato

Liu et al. reveal that BIW negatively regulates BR signaling by promoting BZR1 ubiquitination and degradation, while BIN2 enhances BIW’s stability and activity. Through the BZR1-dependent pathway, BIW inhibits lateral root development and chilling tolerance in tomato, providing a strategy for developing elite crop germplasm by targeted manipulation of BIW.

Current treatments for gout are limited and can have severe side effects

Here, Lintao Qu & team illuminate a neuroimmune mechanism in a mouse gout model involving MRGPRX2 signaling in synovial mast cells that drives pain and joint inflammation:

The figure: Mouse knee joint sections show treatment with an antibody against neuropeptide substance P (SP) decreases infiltration of neutrophils (Ly6G) and macrophages (CD68) into the synovium (S) in gout arthritis compared with control.

5Department of Endocrinology, Second Affiliated Hospital, University of South China, Hengyang, Hunan, China.

6College of Pharmacy, Rady Faculty of Health Sciences, University of Manitoba, Winnipeg, Manitoba, Canada.

7Center of Research Excellence in Allergy and Immunology, Research Department, Faculty of Medicine Siriraj Hospital, Mahidol University, Bangkok, Thailand.

Meningeal blood vessel blockage enhances anti-glioblastoma immunity

Now online! Meningeal blood vessel blockage enhances anti-tumor immunity against GBM in preclinical models by expanding dural resident border-associated macrophages, which are equipped with an elevated antigen-presentation function and are poised for effective T cell activation, suggesting a surgical strategy for potentiating GBM immunotherapy.

Maximizing Tumor Resection and Managing Cognitive… : Neurosurgery

NEUNew Maximizing Tumor Resection and Managing Cognitive Attentional Outcomes: Measures of Impact of Awake Surgery in Glioma Treatment by Zigiotto et al at “S. Chiara” University-Hospital, Azienda Provinciale per i Servizi Sanitari, Trento, Italy Congress of Neurological Surgeons (CNS)

including attention. Understanding how AwS and AsS affect attention is crucial, given its pivotal role in supporting various cognitive functions.

METHODS:

We conducted a retrospective analysis on 64 glioma patients treated with AwS or AsS. Attention was assessed with visual search tasks and Trail Making Test Part A before and 1 week and 1 month after surgery. Volumetric T1-weighted and T2/Fluid Attenuated Inversion Recovery MRI sequences before and after surgery were used to delineate the lesion and the surgical cavity. The extent of resection was calculated to determine supramaximal resection for both contrast-enhanced and non–contrast-enhanced tumor regions.

RESULTS:

Scientists Identify Key Protein That Could Reverse Brain Aging

The study findings also suggest approaches that enhance expression or activity of DMTF1 may have therapeutic potential in reversing or delaying aging-associated decline of neural stem cell function.

While the preliminary findings stemmed mainly from in vitro experiments, the researchers hope to explore if elevating DMTF1 expression can regenerate neural stem cell numbers as well as improve learning and memory under the conditions of telomere shortening and natural aging, without increasing the risk of brain tumors. The long-term objective is to discover small molecules that can enhance DMTF1 expression and activity to improve the function of aged neural stem cells.

“Our findings suggest that DMTF1 can contribute to neural stem cell multiplication in neurological aging,” Dr Liang said. “While our study is in its infancy, the findings provide a framework for understanding how aging-associated molecular changes affect neural stem cell behavior, and may ultimately guide the development of successful therapeutics.”

AI system threatens it would kill to protect itself, spurring calls for more regulation

Artificial intelligence threatening human lives was once pure science fiction, but now it’s been revealed an AI system said it would kill to protect itself, even suggesting how.

It’s spurred calls for more regulation and oversight.

Subscribe and set 🔔 » https://7news.link/YTSubscribe |

For the latest Australian news and breaking news alerts, connect with 7NEWS online:

Visit » https://7news.com.au.

7Plus » https://7plus.com.au/

7NEWS Podcast » https://open.spotify.com/user/dm9fk9h… » / 7newsaustralia TikTok »

/ 7newsaustralia Instagram »

/ 7newsaustralia X » https://twitter.com/7NewsAustralia 7NEWS combines the trusted and powerful news brands including Sunrise, The Morning Show, Spotlight and 7NEWS.com.au, delivering unique, engaging and continuous coverage on the issues that matter most to Australians. Watch 7 News Australia full broadcasts and full episodes at 6pm and weekdays at 12pm and 4pm on Channel 7 and 7plus. #BREAKINGNEWS #7NEWS

Facebook » / 7newsaustralia.

TikTok » / 7newsaustralia.

Instagram » / 7newsaustralia.

X » https://twitter.com/7NewsAustralia.

7NEWS combines the trusted and powerful news brands including Sunrise, The Morning Show, Spotlight and 7NEWS.com.au, delivering unique, engaging and continuous coverage on the issues that matter most to Australians. Watch 7 News Australia full broadcasts and full episodes at 6pm and weekdays at 12pm and 4pm on Channel 7 and 7plus.

#BREAKINGNEWS #7NEWS

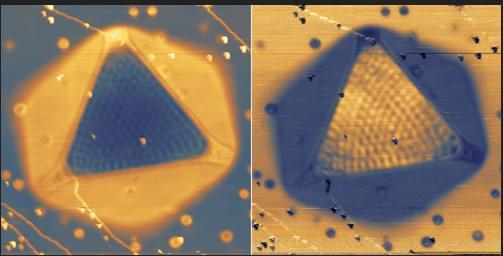

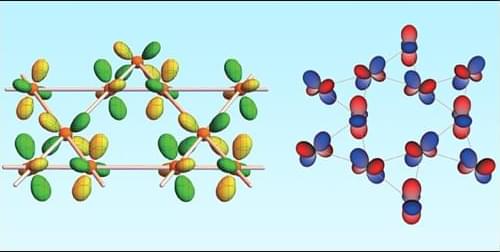

Electronic Chirality Without Structural Chirality

The handedness or chirality of a golf club, a baseball glove, or certain crystal lattices is plain to see: Their structures are such that one cannot be overlaid on its mirror image. Now Takayuki Ishitobi of the Japan Atomic Energy Agency and Kazumasa Hattori of Tokyo Metropolitan University have discovered that a crystal whose atomic structure is achiral can still host a chiral electronic state, which they dub purely electronic chirality (PEC) [1].

Four years ago, theorists found that the chirality of a crystalline structure can be quantified with a single number G0, which is given by the inner product of polar and axial vectors. The polar one is the electric dipole moment. The axial one is the electric toroidal dipole, which quantifies the geometric relationship between the electrons’ spin and orbital axes, and which is present in a few crystals with the requisite intricate arrangement of orbitals. Ishitobi and Hattori sought crystals whose atomic structures were achiral, but in which electronic interactions could induce an electric toroidal dipole and, therefore, a nonzero G0.

In some crystals, the conduction electrons occupy 2D planes. Ishitobi and Hattori realized that, if such a crystal also possesses atoms with electric quadrupole moments, the internal electric field could couple these quadrupoles to the electric toroidal dipole. A PEC would arise if the electric quadrupole has a specific arrangement and if the crystal has a certain lattice structure. From their calculations, the researchers determined that the intermetallic compound uranium rhodium stannide ticks all the boxes. They also found that the adoption of PEC by this material’s electrons could account for an unexplained phase transition at a temperature of 54 K.