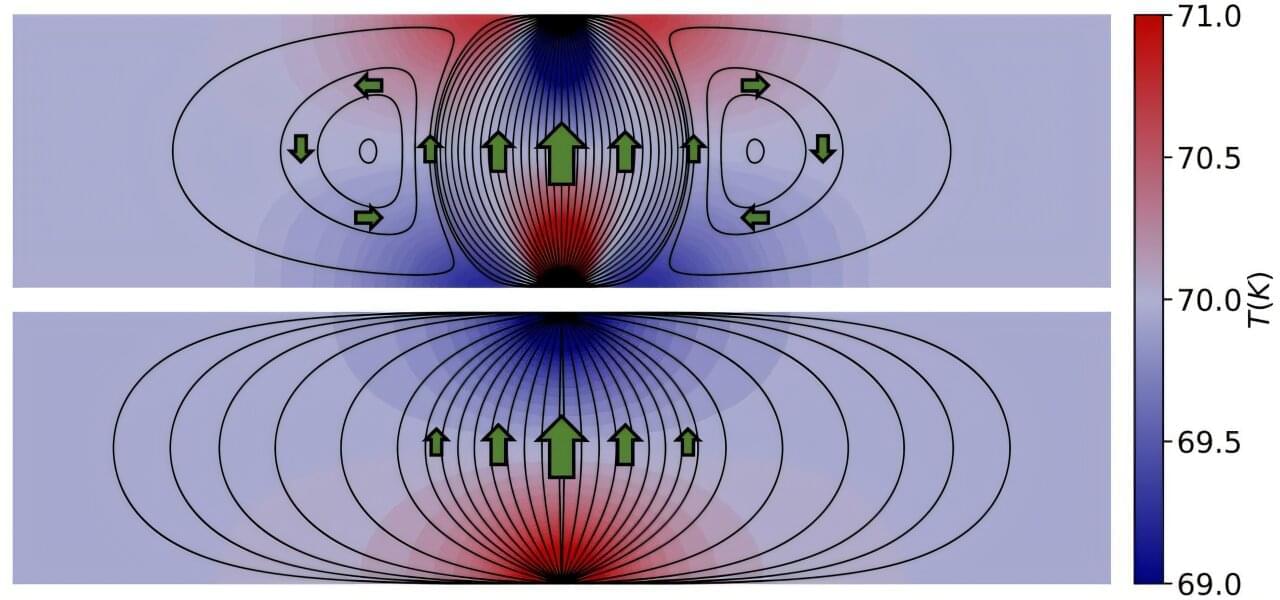

When we think about heat traveling through a material, we typically picture diffusive transport, a process that transfers heat from high-temperature to low-temperature as particles and molecules bump into each other, losing kinetic energy in the process. But in some materials, heat can travel in a different way, flowing like water in a pipeline that—at least in principle—can be forced to move in a direction of choice. This second regime is called hydrodynamic heat transport.

Heat conduction is mediated by movement of phonons, which are collective excitations of atoms in solids, and when phonons spread in a material without losing their momentum in the process, you have phonon hydrodynamics.

The phenomenon has been studied theoretically and experimentally for decades, but is becoming more interesting than ever to experimentalists because it features prominently in materials like graphene, and could be exploited to guide heat flow in electronics and energy storage devices.