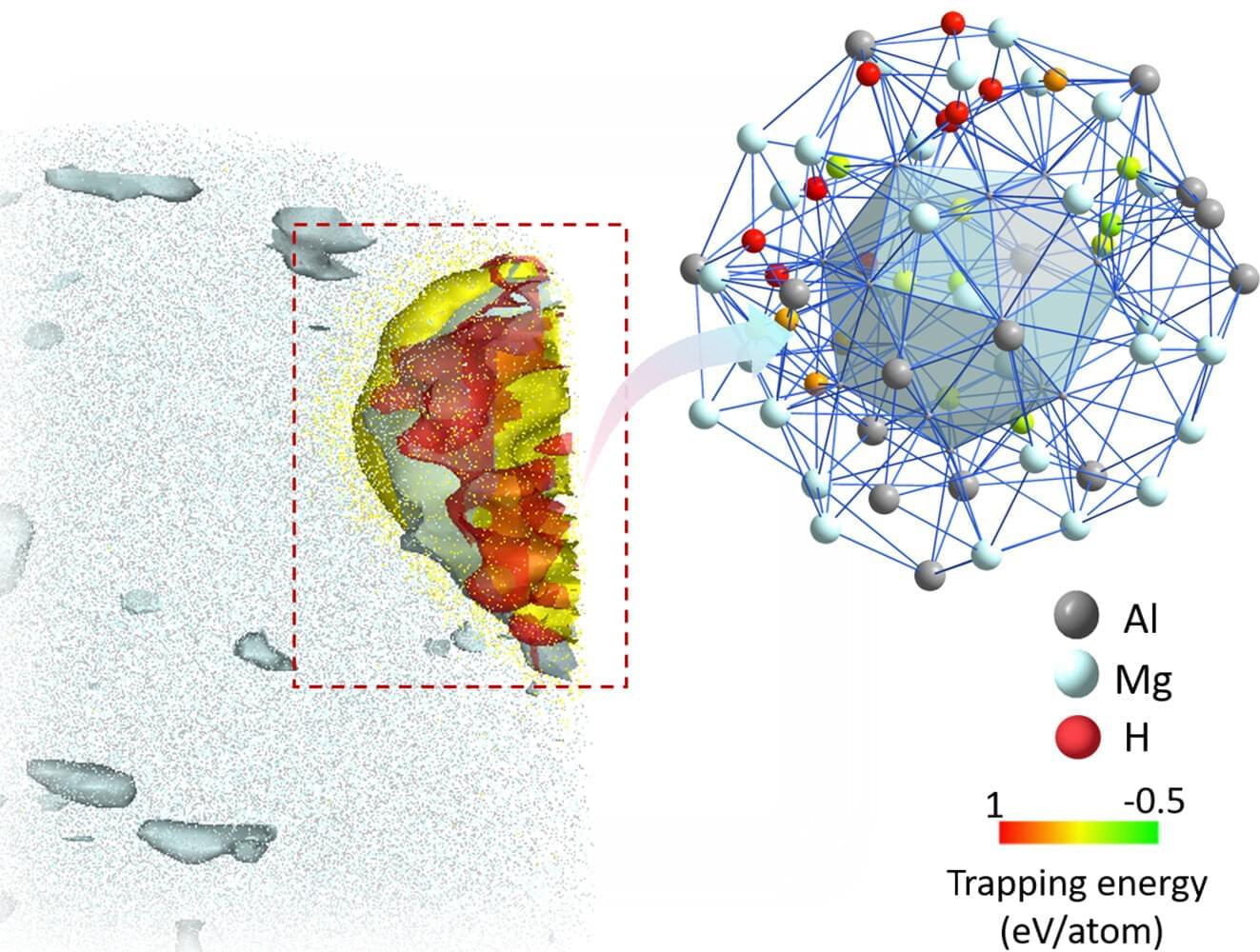

Aluminum alloys are well-known for their low weight and corrosion resistance, making them ideal candidates for applications in a low-carbon economy—from lightweight automobiles to tanks for storing green hydrogen. However, their widespread application is limited by a key challenge: they suffer from embrittlement leading to cracking and failure when exposed to hydrogen. Until now, alloys resistant to hydrogen embrittlement were rather soft, limiting their application in hydrogen-related technologies that require high strength.

Now, researchers from the Max Planck Institute for Sustainable Materials (MPI-SusMat) in Germany, together with partners from China and Japan, have developed a new alloy design strategy that overcomes this dilemma. Their approach enables both exceptional strength and superior resistance to hydrogen embrittlement (HE), paving the way for safer and more efficient aluminum components in the hydrogen economy. They have published their results in the journal Nature.