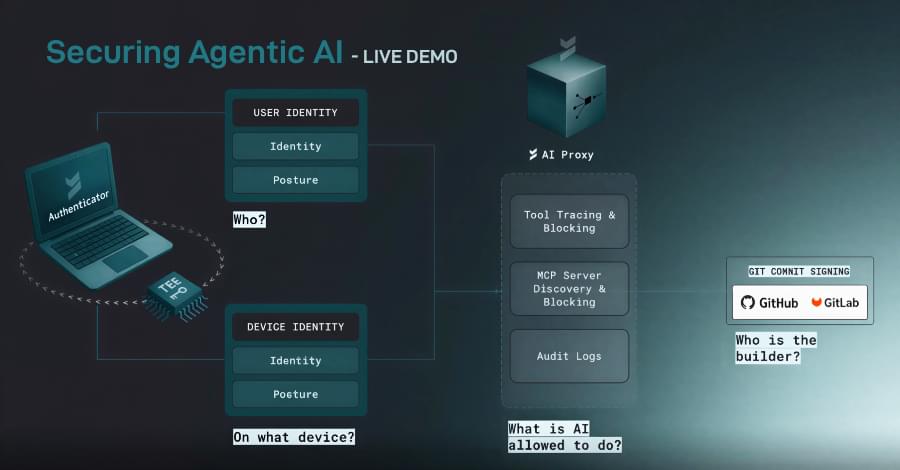

AI agents now build and run software automatically. Insecure MCPs and CVE-2025–6514 show how trusted automation enables code execution attacks.

To learn more about the non-security updates released today, you can review our dedicated articles on the Windows 11 KB5074109 & KB5073455 cumulative updates and Windows 10 KB5073724 extended security update.

This month’s Patch Tuesday fixes one actively exploited and two publicly disclosed zero-day vulnerabilities.

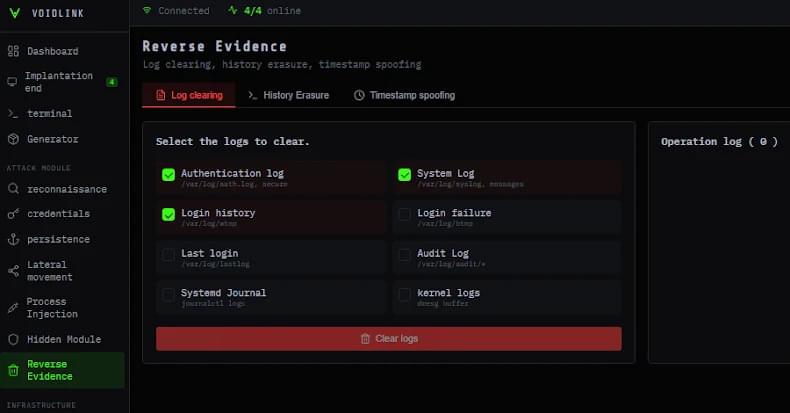

A newly discovered advanced cloud-native Linux malware framework named VoidLink focuses on cloud environments, providing attackers with custom loaders, implants, rootkits, and plugins designed for modern infrastructures.

VoidLink is written in Zig, Go, and C, and its code shows signs of a project under active development, with extensive documentation, and likely intended for commercial purposes.

Malware analysts at cybersecurity company Check Point say that VoidLink can determine if it runs inside Kubernetes or Docker environments and adjust its behavior accordingly.

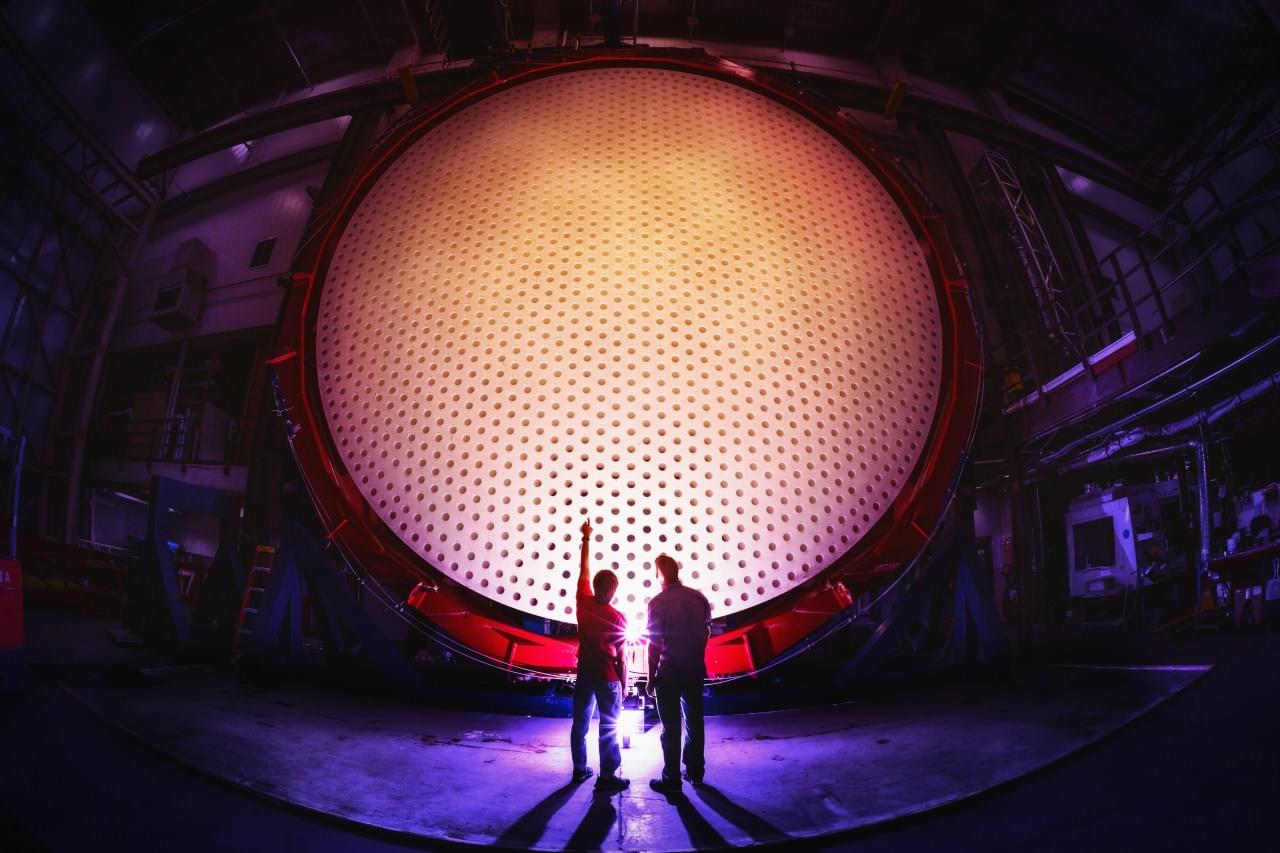

AUSTIN (KXAN) — The group building what could become the world’s most powerful optical telescope, the Giant Magellan, has a new leader. The GMTO Corporation announced Tuesday that The University of Texas at Austin’s Daniel T. Jaffe will serve as its new president.

Jaffe joins fellow UT professor Taft Armandroff, who was elected in November to chair the GMTO board of directors.

“I’m very excited about the chance to lead this project. I’m very enthusiastic about its prospects. I think it’s going to be a major breakthrough for astronomical science in the coming decades,” Jaffe said.

In 2024, scientists stumbled upon a potential new treatment for hereditary-patterned baldness, the most common cause of hair loss in both men and women worldwide.

It began with research on a naturally occurring sugar that helps form DNA: the ‘deoxyribose’ part of deoxyribonucleic acid.

While studying how these sugars aid wound healing in mice when applied topically, scientists at the University of Sheffield and COMSATS University in Pakistan noticed that the fur around treated lesions grew back faster than in untreated mice.

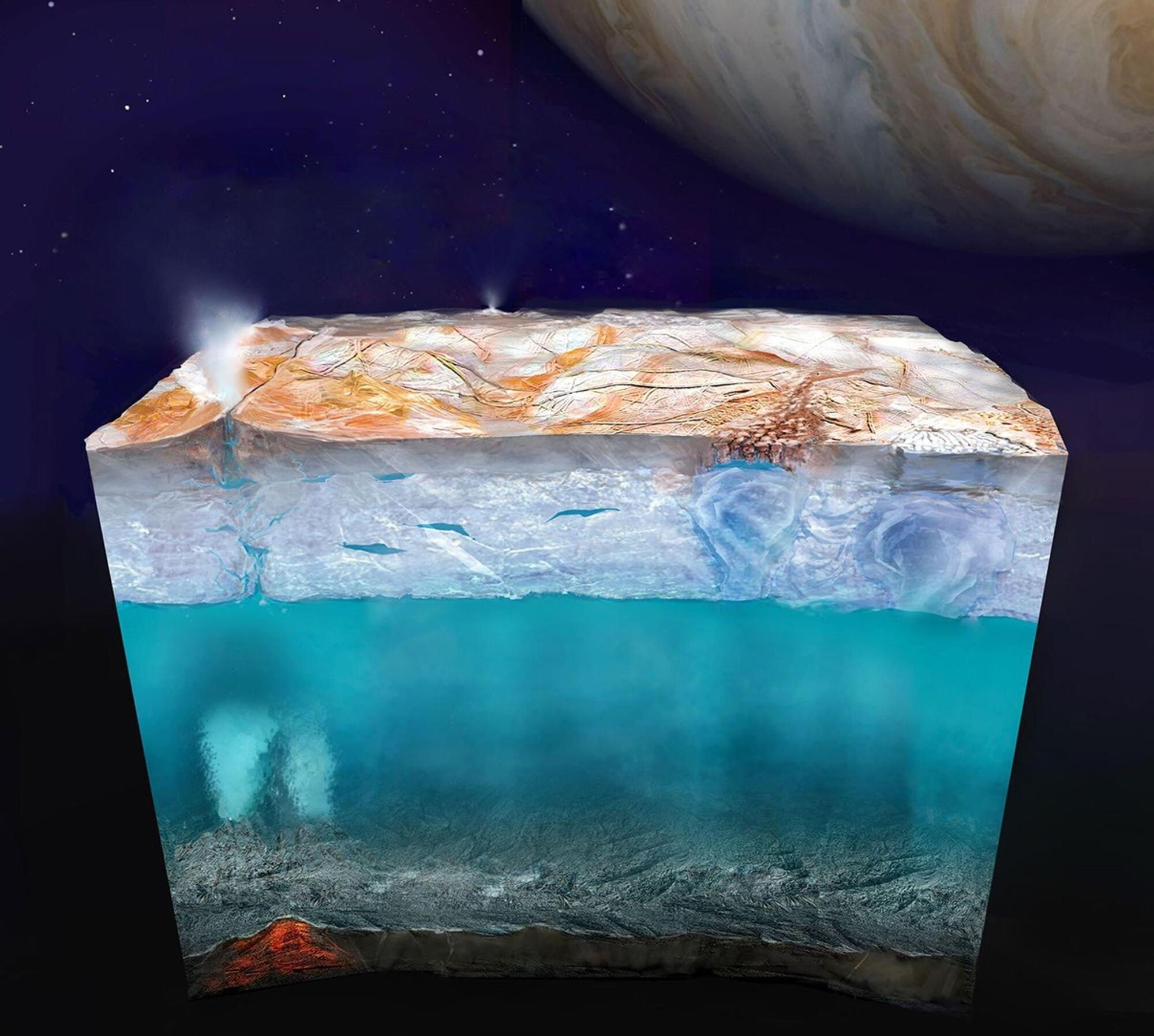

“If we could explore that ocean with a remote-control submarine, we predict we wouldn’t see any new fractures, active volcanoes or plumes of hot water on the seafloor,” said Dr. Paul Byrne.

Does Jupiter’s icy moon, Europa, contain the conditions for life as we know it? This is what a recent study published in Nature Communications hopes to address as a team of scientists from the United States and Canada investigated the likelihood of Europa’s subsurface ocean having the right conditions for life to exist. This study has the potential to help scientists better understand the necessary conditions for where life could exist, along with developing the methods for understanding them.

For the study, the researchers used a series of computer models to simulate potential tectonic activity on the seafloor of Europa’s subsurface ocean. The reason for studying tectonic activity on Europa is because this geological process is a key driver of life both existing and thriving on Earth. This is because plate tectonics are responsible for recycling nutrients to and from the Earth’s interior as it recycles materials like rocks and dust. This also enables the flow of water from the Earth’s interior to the seafloor. The researchers examined a myriad of mechanisms, including tidal forces, mantle convection, global contraction, and water-rock interactions (serpentinization).

In the end, the researchers found that Europa potentially does not exhibit these mechanisms to enable plate tectonics to be produced on Europa. They conclude that the liquid water making its way to the seafloor only occurs in the first few hundred feet, whereas plate tectonics occur over hundreds of miles. Finally, they conclude that is Europa does have life, they plate tectonics isn’t responsible for it.

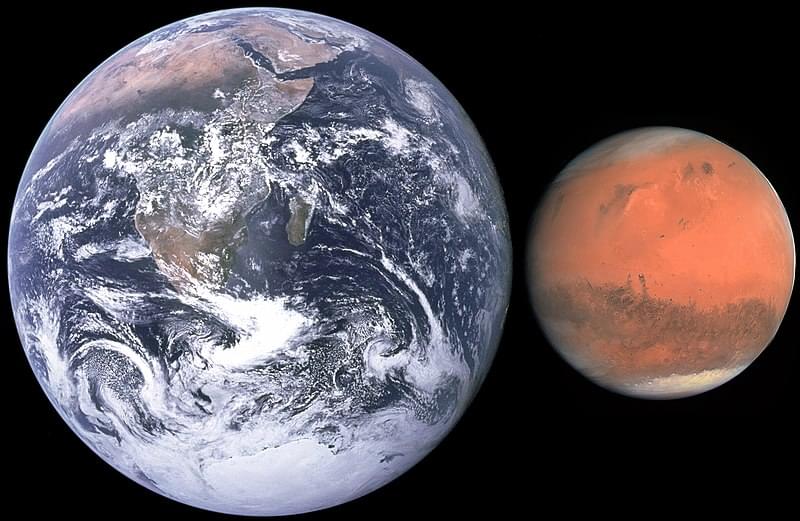

“I knew Mars had some effect on Earth, but I assumed it was tiny,” said Dr. Stephen Kane.

How does Mars influence Earth’s climate cycles? This is what a recent study published in the Publications of the Astronomical Society of the Pacific hopes to address as a trio of researchers from the United States, United Kingdom, and Australia investigated how the gravitational interactions between Earth and Mars help alter the former’s climate evolution. This study has the potential to help scientists better understand how external processes influence planetary habitability and what this could mean for finding life beyond Earth.

For the study, the researchers used a series of computer models to simulate Earth Milankovitch cycles, which are changes in Earth’s eccentricity (orbit shape), obliquity (axial tilt), and precession (axial wobble) over hundreds of thousands of years. Specifically, the researchers aspired to ascertain how gravitational interactions with Mars could influence these cycles, including climate evolution like ice ages.

In the end, the researchers found that Mars not only influences Earth’s orbital patterns and behavior, but that the solar system’s architecture influences each other’s orbital patterns, and this could have implications for searching for Earth-like exoplanets. This comes despite Mars being approximately half the size of Earth.