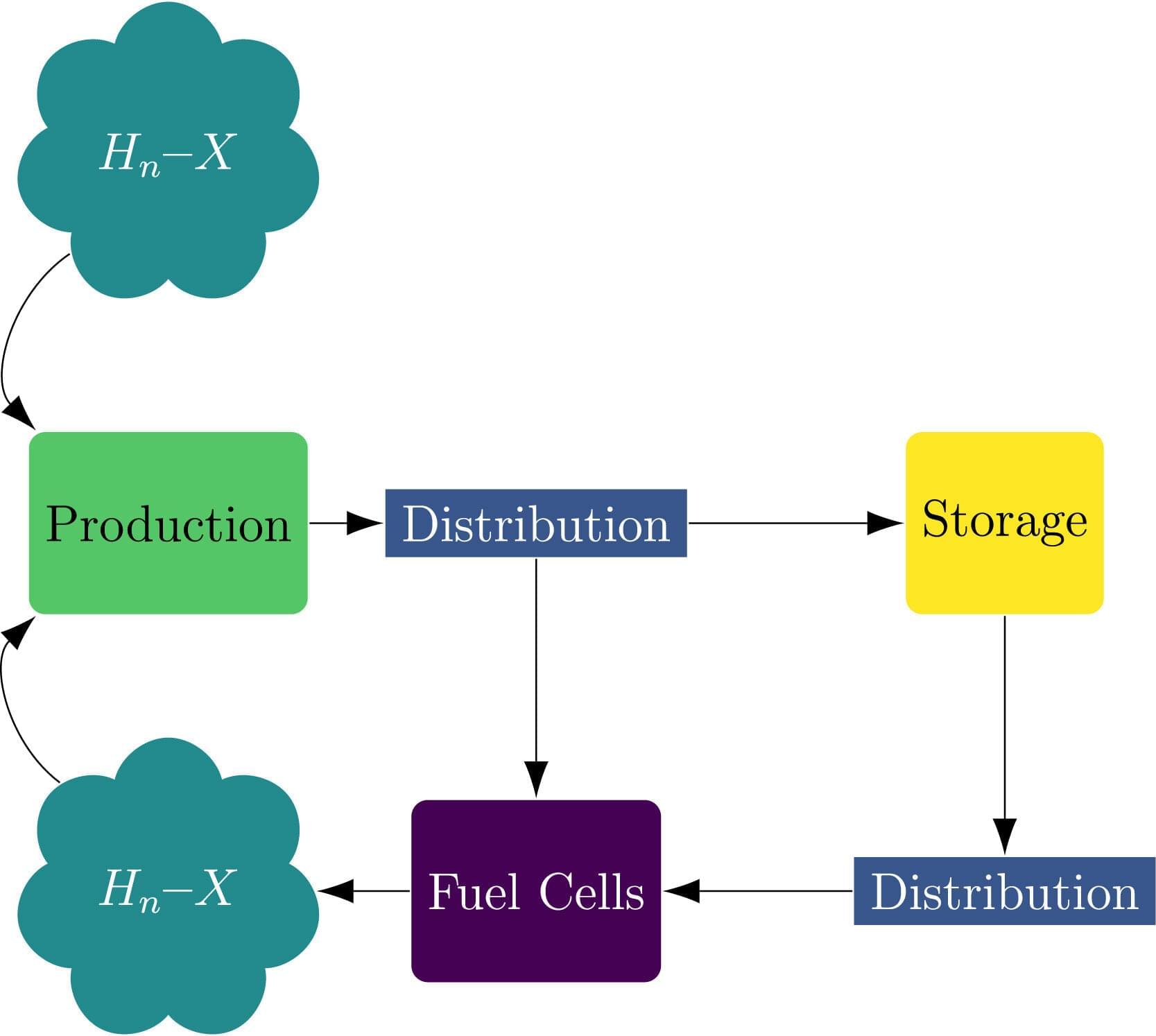

Florida State University researchers have discovered a pathway within a certain type of molecule that limits chemical reactions by redirecting light energy. The study could enable development of more efficient reactions for pharmaceuticals and other products.

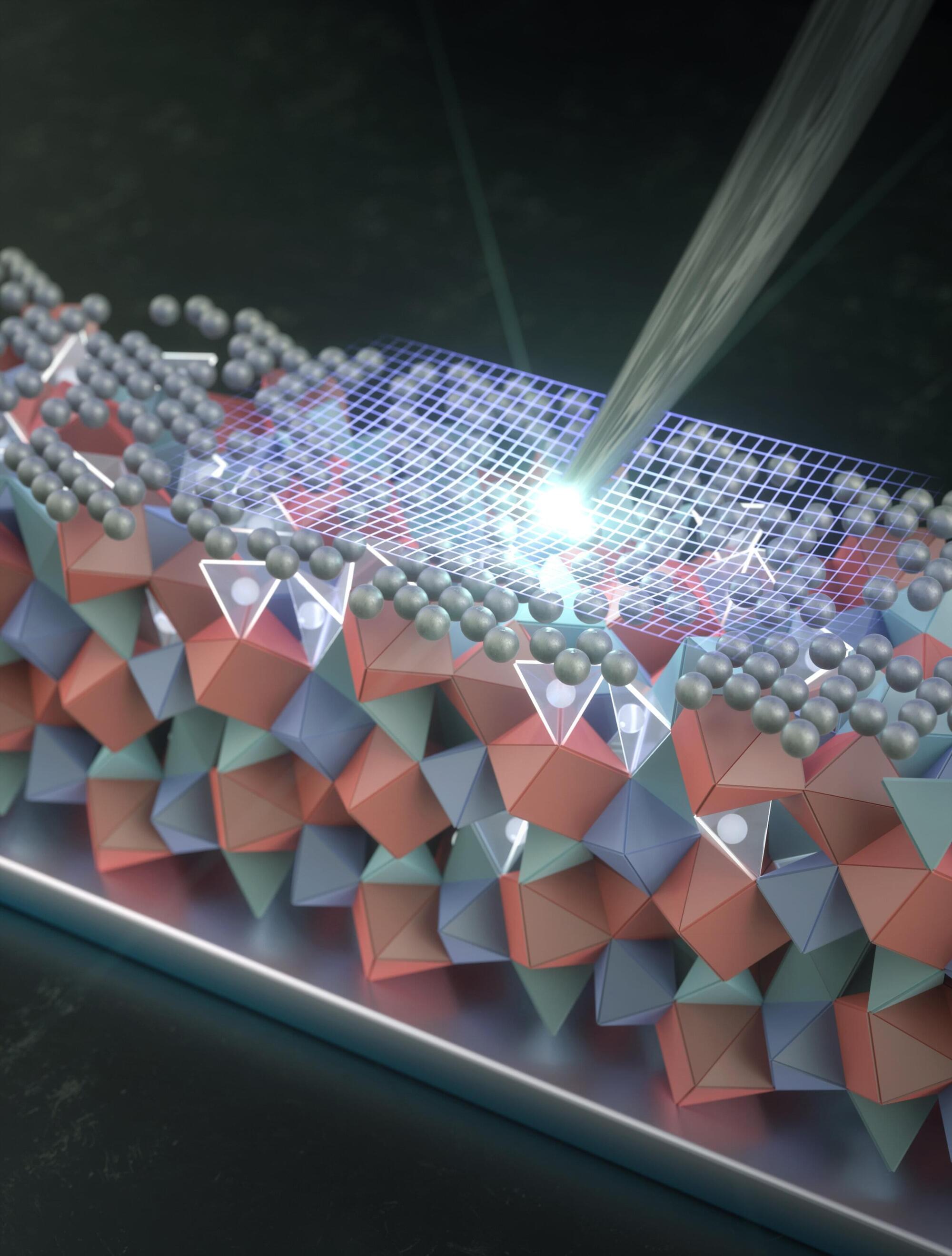

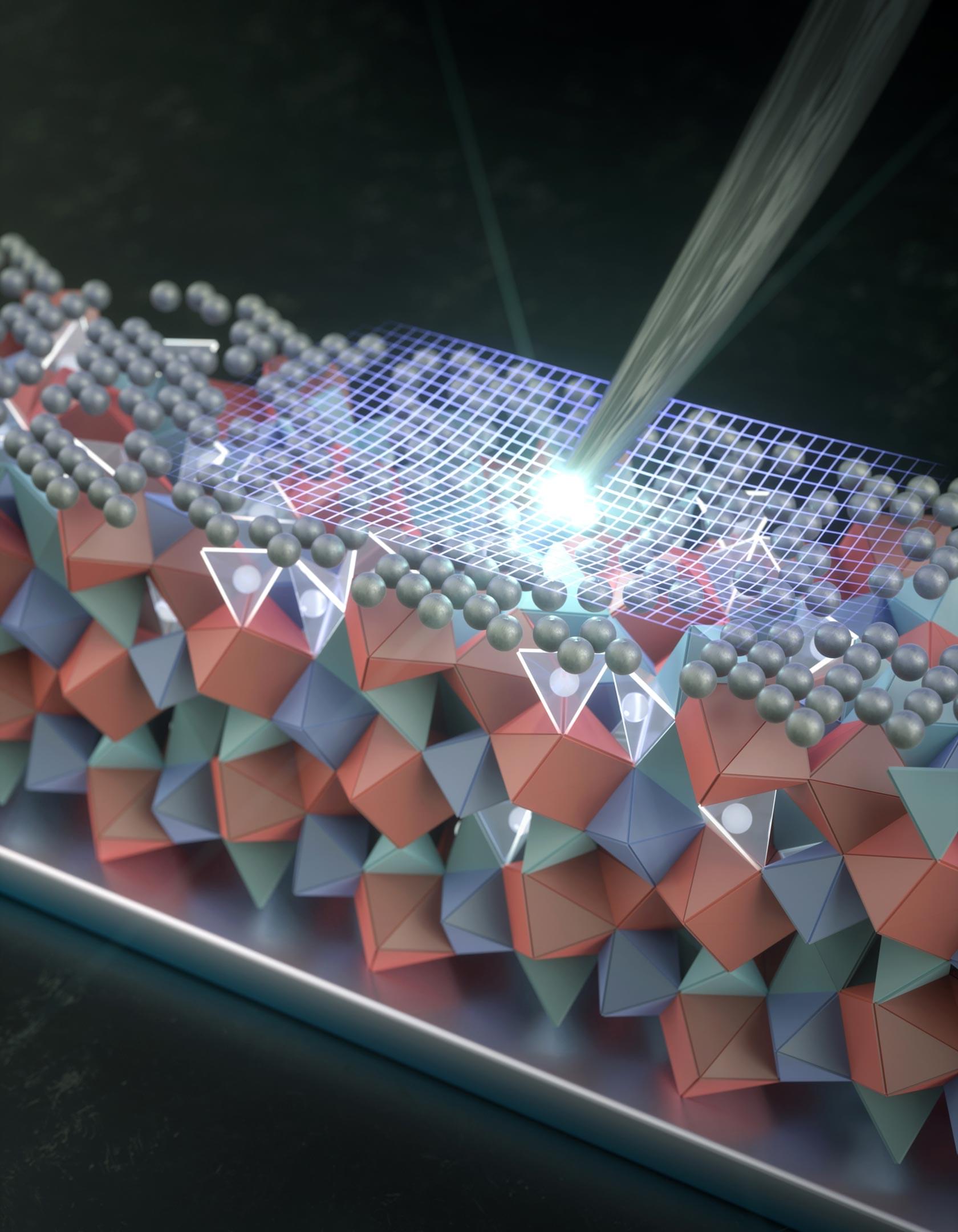

The researchers examined ligand-to-metal photocatalysts. Ligands are a molecule bound to a larger molecule; in this case, to a metal. Photocatalysts are materials that use light to accelerate a chemical reaction. Theoretically, these molecules should be readily able to harness light energy toward chemical reactivity. But in experiments, chemists only found inefficient reactions.

The FSU research, published in the Journal of the American Chemical Society, shows why: The molecule quickly moves into a less energetic state before the absorbed energy can break chemical bonds. The energy is drained too quickly into the wrong place, so bond-breaking is limited.