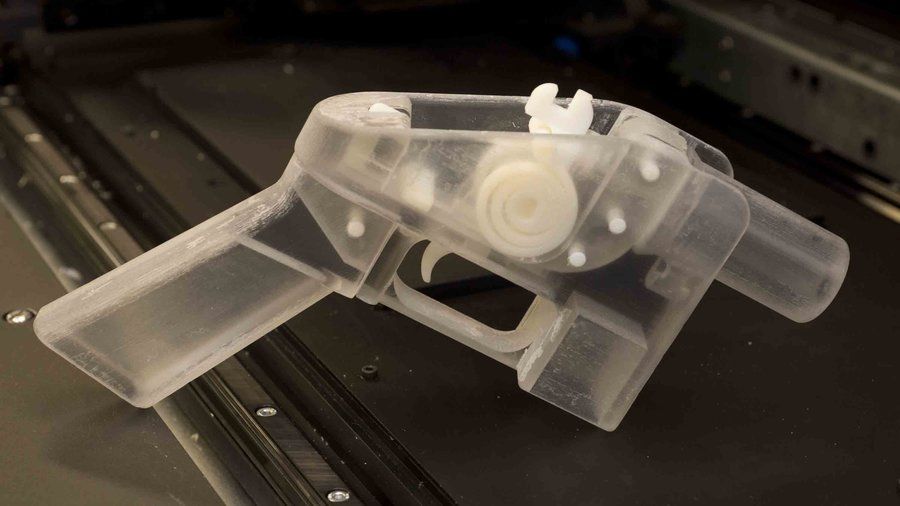

High-tech warfare at knife-fight ranges: that’s the ugly future of urban combat. If you thought Baghdad was bad, with its roughly six million people, imagine a “megacity” of 10 or 20 million, where the slums have more inhabitants than some countries. Imagine a city of the very near future where suspicious locals post every US military movement on Twitter with digital photos and GPS-precise coordinates. Imagine roadside bombs that fly because the bad guys downloaded blueprints for a kamikaze mini-drone and built it with their 3D printer.

As the US pulls out of the mountains and deserts of Afghanistan, the Navy and Air Force may be looking to the wide-open Pacific, but the Army is increasingly concerned about the cramped alleyways of Third World cities. (The Marines, as usual, have a foot in both worlds). Chief of Staff Ray Odierno’s personal Strategic Studies Group — now led by hybrid warfare expert David Johnson — is working on the subject, as is the Army’s think tank and teaching institution, Training and Doctrine Command (TRADOC). This August, after months of seminars, simulations, and study, the Army War College will host a “deep future wargame” set in a megacity, probably a coastal one, circa 2035.

“We talk about the danger of failed states: Imagine a failed megacity,” offers Col. Kevin Felix of TRADOC’s Army Capability Integration Center (ARCIC), which plays a leading role in organizing the wargame. Even a partial breakdown of security and public services could put thousands of people in peril — or under the rule of drug gangs, as in Brazil’s infamous favelas; or of terrorist groups, like Hezbollah in parts of Lebanon. In those parts of the city, Felix told me, “there may be order, but I wouldn’t define it as law and order.”