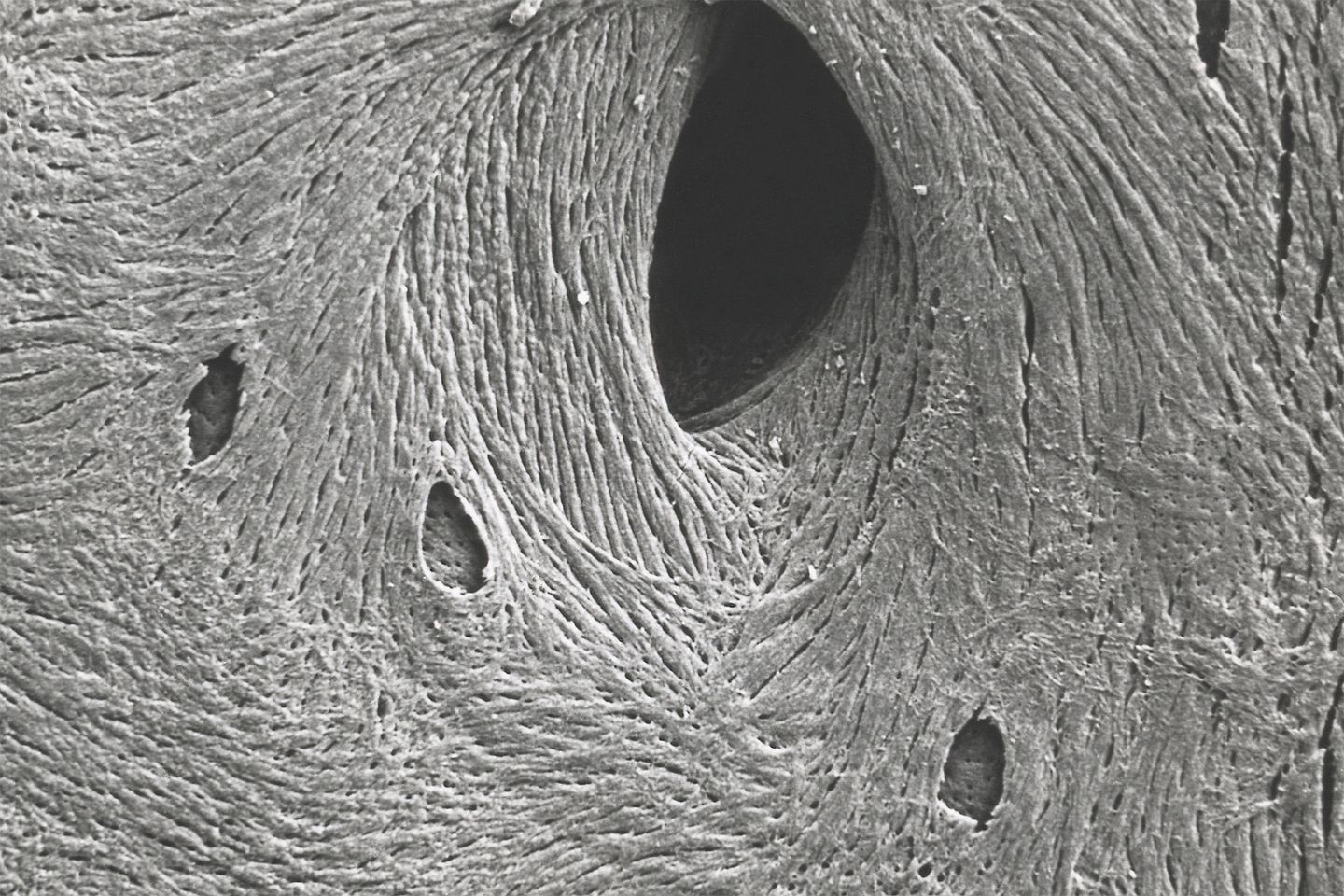

A team from the Universities of Glasgow, Strathclyde, the West of Scotland and Galway have created a device that sends nano vibrations across mesenchymal stem cells suspended in a collagen gel.

The authors of the paper, published in the Nature Biomedical Engineering journal, found that these tiny vibrations turn the cells into a 3D model of mineralised bone ‘putty’. This putty isn’t quite as hard as bone at this stage. That’s where the body comes in.

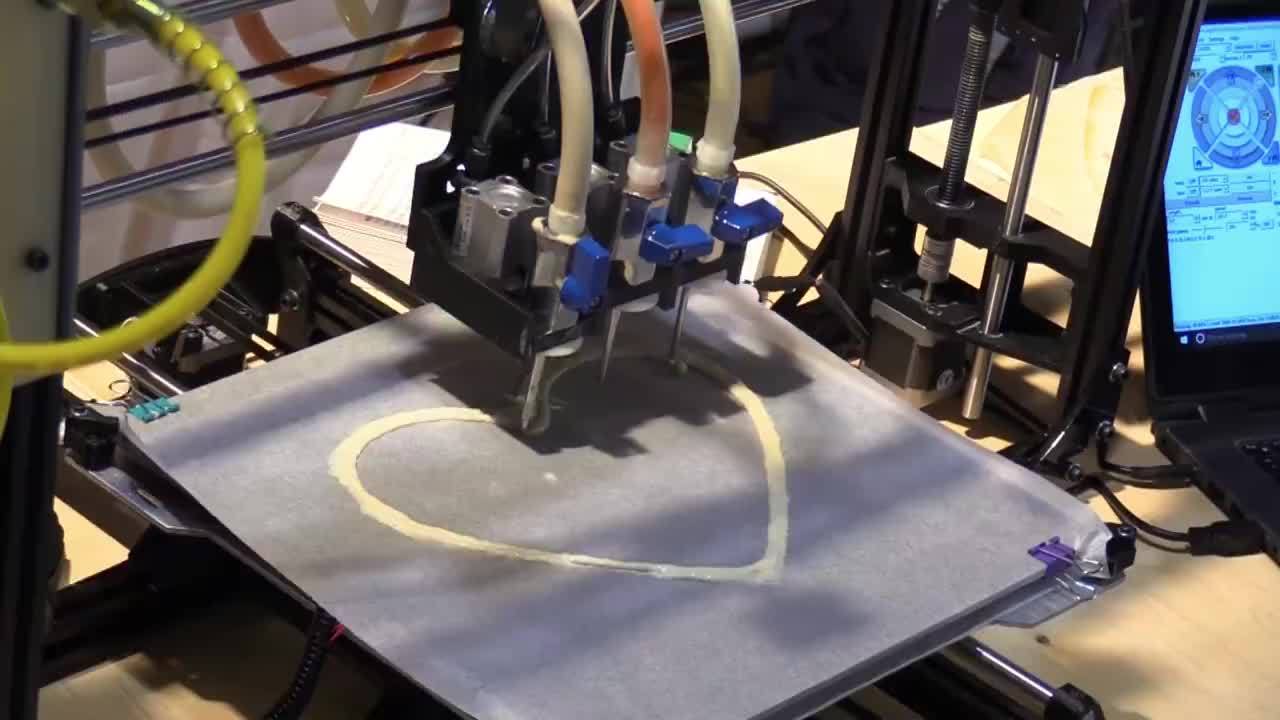

“We add the bone putty to an anatomically correct, rigid living scaffold, that we made by 3D printing collagen,” says Matthew Dalby, professor of cell engineering at the University of Glasgow, and one of the lead authors of the paper. “We put lots of cells in the body so it has a chance to integrate this new bone. We tell the cells what to do in the lab, then the body can act as a bioreactor to do the rest.”

Scientists have grown living bone in the lab by sending vibrations through stem cells. It could help amputees and people with osteoporosis.