Tungsten carbide–cobalt (WC–Co) is prized for its hardness, but that same property makes it unusually difficult to shape. The current process is wasteful and expensive for the yield produced, and an economically sensible method for creating these materials is long overdue.

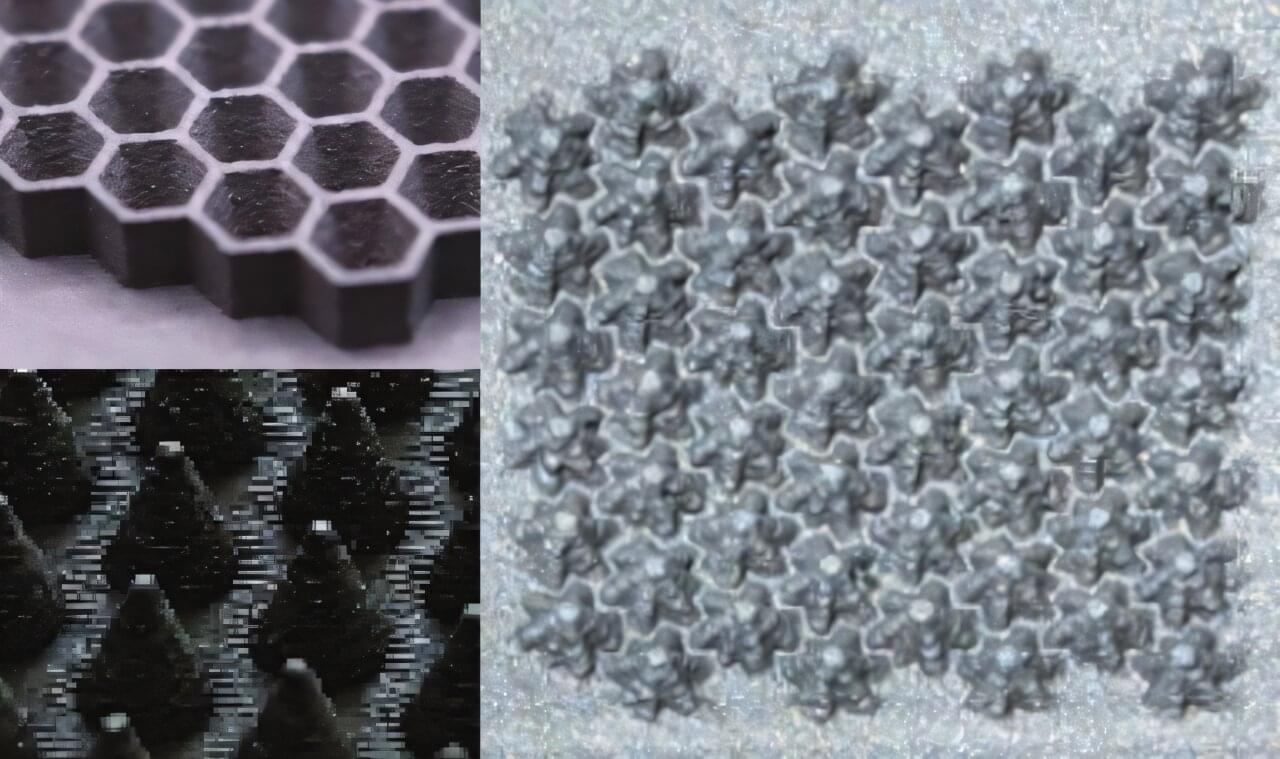

WC-Co cemented carbides are important in fields that require high wear resistance and hardness, such as cutting and construction tools. Currently, these carbides are made using powder metallurgy, utilizing high pressure and sintering machines to combine the WC and Co powders to yield a manufactured cemented carbide.

Though this method does produce highly durable and hard final products, a lot of expensive material is used, and the yield is suboptimal.