As neural-adaptive electronic wearables become more common, they are quietly reshaping technology, cognition, and society.

Get the latest international news and world events from around the world.

Scientists say evolution works differently than we thought

As species evolve, random genetic mutations arise. Some of these mutations become fixed, meaning they spread until every individual in a population carries the change. The Neutral Theory of Molecular Evolution argues that most mutations that reach this stage are neutral. Harmful mutations are quickly eliminated, while helpful ones are assumed to be extremely rare, explains evolutionary biologist Jianzhi Zhang.

Zhang and his colleagues set out to test whether this idea holds up when examined more closely. Their results pointed to a major problem. The researchers found that beneficial mutations occur far more often than the Neutral Theory allows. At the same time, they observed that the overall rate at which mutations become fixed in populations is much lower than would be expected if so many helpful mutations were taking hold.

Are Alien Machines Wiping Out Civilisations? | The Berserker Hypothesis

Are alien machines hunting civilisations, one by one, until only silence remains?

Support The Omega Signal: https://buymeacoffee.com/theomegasit.

Keep the signal strong. Every space latte powers the next transmission.

The universe should be full of alien civilisations. Billions of stars, billions of planets… yet all we hear is silence. This mystery is known as the Fermi Paradox. But what if the silence isn’t natural? What if it’s enforced?

The Berserker Hypothesis suggests that advanced civilisations may have unleashed self-replicating machines designed to seek out and exterminate intelligent life. These deadly Von Neumann probes could roam the galaxy, wiping out civilisations one by one, leaving behind only empty, lifeless worlds.

In this video, we explore:

The origins of the Berserker Hypothesis in both science fiction and science.

Emergence — Prof. Philip Clayton

Talk given by Prof. Philip Clayton as part of Summer Course 1

Date: July 20, 2006

Speakers: Prof. Philip Clayton.

Category: Chance, Chance, Emergence, Emergence, Evolution, Human Identity, Human Identity, Philosophy Of Science.

Audience: Intermediate.

Context: Course.

Course: Summer Course No. 1 — Unit 1: The Big Questions In Science and Religion.

Teens Spend Most School Phone Time on Social Media

“This moves the conversation beyond anecdotes and self-reports to real-world behavior,” said Dr. Jason Nagata.

How much time during school hours do teens spend on social media? This is what a recent study published in JAMA hopes to address as a team of researchers investigated connections between adolescent phone use during school. This study has the potential to help researchers, academic administrators, students, and parents become aware of the connections between adolescent phone use and all-around health.

For the study, the researchers analyzed data regarding smartphone app usage during school hours from 640 adolescents aged 13–18 through software installed on their phones that was approved by all participants and their parents. The goal of the study was to ascertain phone app usage during school hours, with data being obtained from September 2022 to May 2024. In the end, the researchers found that teens spent about 1.16 hours each school day on smartphones, mostly using social media apps, with higher use among older students and those from underprivileged households.

Why SpaceX Is Worth Trillions With Only $15B of Revenue

SpaceX’s valuation has the potential to reach $1.5 trillion due to its innovative technologies, including reusable rockets, Starship, and Starlink, which could revolutionize the space industry and unlock massive growth opportunities in areas such as satellite connectivity, data centers, and computing ## Questions to inspire discussion.

Starship Production & Economics.

🚀 Q: What is SpaceX’s Starship production target and cost reduction goal? A: SpaceX plans to manufacture 1,000 Starships per year by 2030 (with aspirational goals of 10,000 per year), reducing launch costs to $10/kg through fully reusable vehicles achieving 99% reliability and 30 flights per booster.

🎯 Q: When will Starship begin commercial payload launches? A: Starship is currently in testing phase with proven relighting, PEZ dispenser deployment, and large payload capacity, expected to achieve commercial readiness as reliability approaches 99% through iterative flight testing.

Starlink V3 Revenue Model.

💰 Q: What revenue will Starlink V3 generate for SpaceX? A: Starlink V3 constellation will generate $250B revenue with 50% profit margins, representing 90–95% of SpaceX’s revenue over the next 5 years according to Mach33 and ARK Invest modeling.

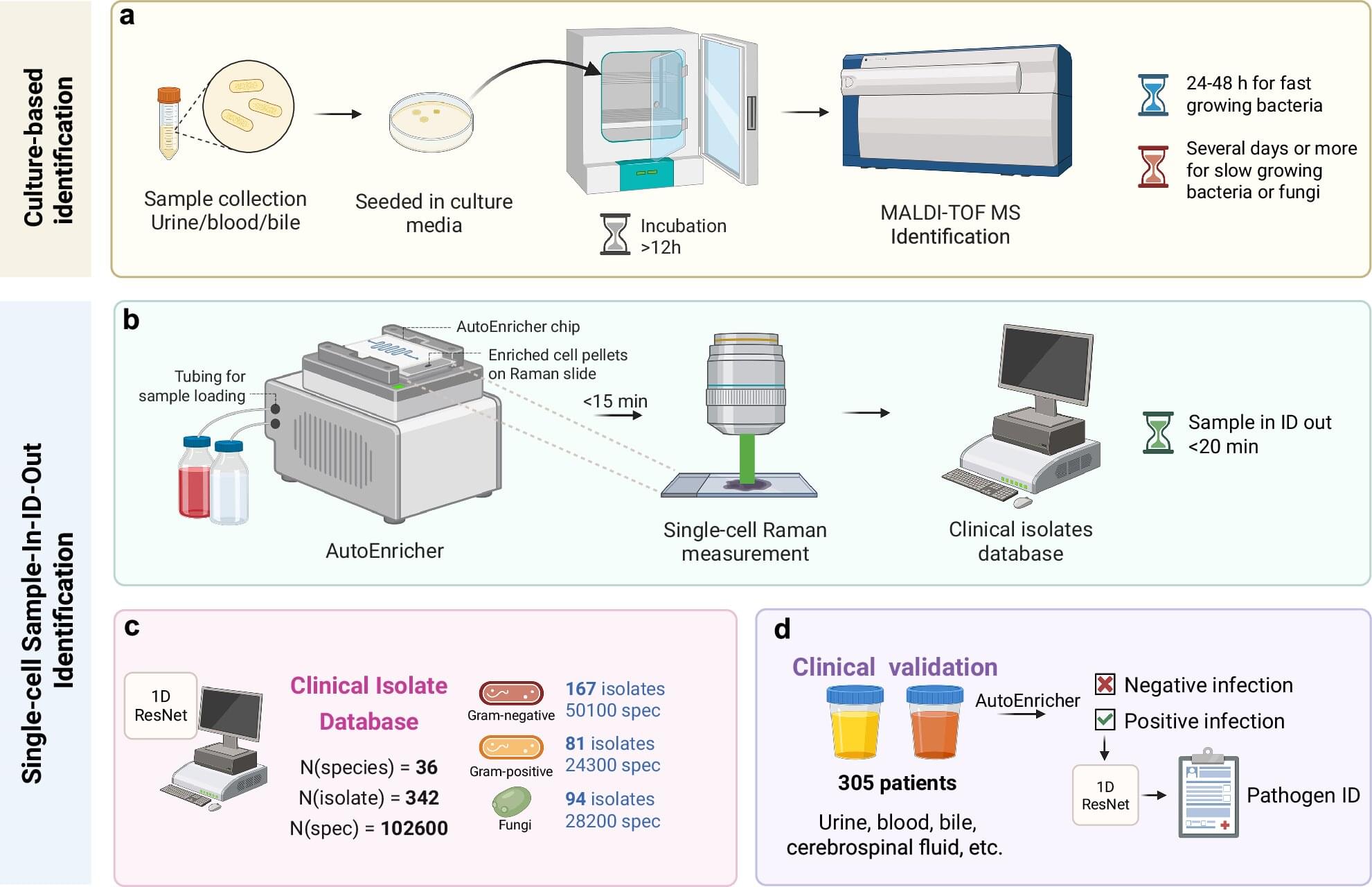

System can diagnose infections in 20 minutes, aiding fight against drug resistance

A new technique which slashes the time taken to diagnose microbial infections from days to minutes could help save lives and open up a new front in the battle against antibiotic resistance, researchers say.

Engineers and clinicians from the UK and China are behind the breakthrough system, called AutoEnricher. It combines microfluidic technology with sophisticated analysis and machine learning to enable the diagnosis of pathogens in just 20 minutes.

The team’s paper, titled “Rapid culture-free diagnosis of clinical pathogens via integrated microfluidic-Raman micro-spectroscopy,” is published in Nature Communications.

A traditional Brazilian plant shows unexpected strength against arthritis

A humble Brazilian coastal plant used in folk medicine is now backed by science as a potential natural fighter against inflammation and arthritis.

A research team in Brazil has found strong evidence that the Joseph’s Coat plant (Alternanthera littoralis) is both safe and effective at reducing inflammation, easing pain, and protecting against arthritis. The study was carried out by scientists from the Federal University of Grande Dourados (UFGD), the State University of Campinas (UNICAMP), and São Paulo State University (UNESP).

Joseph’s Coat grows naturally along Brazil’s coastline and has long been used in traditional medicine to treat inflammation, infections, and parasitic illnesses. Despite its widespread use, there had been little scientific research confirming whether these benefits were real or whether the plant was safe.