Looks like there is another way to use plastic bottles.

Why not use your old plastic bottles as the joining material?

Scientists have created a super white paint that is the yin to Vantablack’s yang.

While ultra black materials can today absorb more than 99.96 percent of sunlight, this new super white coat can reflect 95.5 percent of all the photons that hit it.

Instead of warming up under direct light, objects painted with this new acrylic material can remain cooler than their surrounding temperature even under the Sun, which could allow for a new energy-efficient way to control temperature inside buildings.

Circa 2019

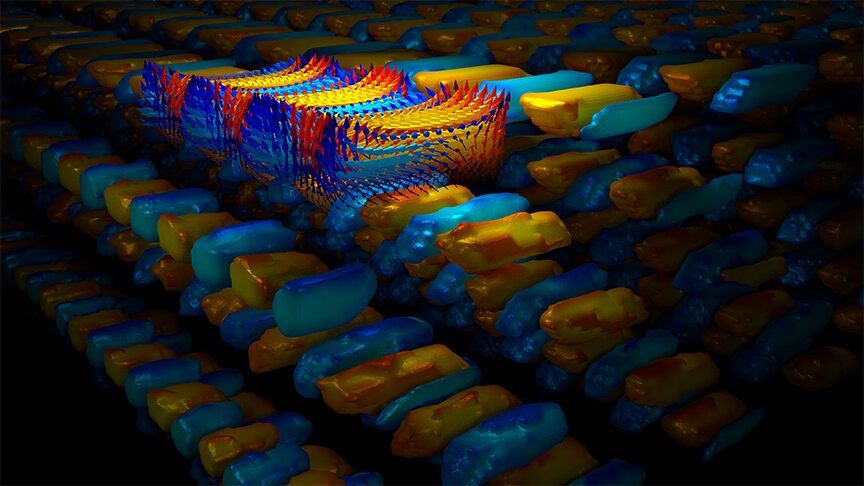

“Frustration” plus a pulse of laser light resulted in a stable “supercrystal” created by a team of researchers led by Penn State and Argonne National Laboratory, together with University of California, Berkeley, and two other national laboratories.

This is one of the first examples of a new state of matter with long-term stability transfigured by the energy from a sub-pico-second laser pulse. The team’s goal, supported by the Department of Energy, is to discover interesting states of matter with unusual properties that do not exist in equilibrium in nature.

“We are looking for hidden states of matter by taking the matter out of its comfortable state, which we call the ground state,” says the Penn State team leader Venkatraman Gopalan, professor of materials science. “We do this by exciting the electrons into a higher state using a photon, and then watching as the material falls back to its normal state. The idea is that in the excited state, or in a state it passes through for the blink of an eye on the way to the ground state, we will find properties that we would desire to have, such as new forms of polar, magnetic and electronic states.”

Photos of touching down on an asteroid.

On Tuesday, October 20th, NASA made history when the OSIRIS-REx mission successfully completed a “touch-and-go” sample collection maneuver with asteroid 101955 Bennu over 200 million miles away from Earth. And now, we have the timelapse to prove it.

NASA shared a total of 82 images from spacecraft’s SamCam imager covering the approach, the touchdown at sample sight Nightingale, and the “back-away burn.” The slideshow was captured over the course of approximately five minutes, and covers everything from about 82 feet (25 meters) above the asteroid, through the back-away burn, and up until the craft achieved an altitude of approximately 43 feet (13 meters), kicking up a lot of material along the way.

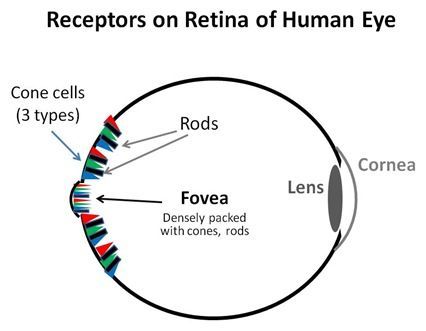

The human eye does not work like a camera, contrary to common belief. Consider the following key factors:

1) Both the cornea and the lens COMBINE to give the focusing effect. Thus it is TWO lenses, not one that allow human vision. In fact the cornea is responsible for two-thirds or more of the focusing effect. The lens compounds that focusing, projecting it from past the pupil onto the curved retina at the back of the eye.

2) The eye corrects for CHROMATIC ABERATION by having a central pit, the FOVEA, where the blue cells are concentrated along the outer rim and the red cells concentrated in the center. Blue light focusses slightly closer to an objective lens and red light slightly further. Thus the red cells are concentrated further back, at the base of the pit, so that the human eye has a natural color correction without the need for complex color corrected lenses.

3) The retina is a curved “screen” at the back of the eye, allowing human vision to encompass an entire hemisphere of 180 degrees in the forwards direction. The retina is mostly rod cells except for at the central fovea, for seeing light but not color and detail, which is why it is easier to see faint objects through a telescope by using what astronomers call “averted vision,” not looking straight at it.

There are thus several factors in trying to use metamaterial lenses to create retinal projection, including:

1) Since the cornea is curved, a tailored curved contact metalens, instead of a flat metalens is ideal.

2) That lens must be able to project a wide-angled view through the lens of the eye, in such a way that the lens distributes the image widely onto the curved retinal screen.

3) If using a third exterior projection system onto that metalens, as with a pair of glasses, googles, or another metalens on top of the first one, it will be a four-lens projection system: projector metalens, contact metalens, human cornea lens, human eye lens. These elements will have to be coordinated into a single system with the final effect.

New technology could deliver “clean, limitless, low-voltage power for small devices”.

The rippling thermal motion of a tiny piece of graphene has been harnessed by a special circuit that delivers low-voltage electrical energy. The system was created by researchers in US and Spain, who say that if it could be duplicated enough times on a chip, it could deliver “clean, limitless, low-voltage power for small devices”.

Brownian motion is the random movement of a tiny particle that is buffeted by atoms or molecules in a liquid or gas – and the idea of harnessing this motion to do useful work has a long and chequered history. In the early 1960s, the Nobel laureate Richard Feynman popularized a thought experiment known as the “Brownian ratchet”, which had been conceived in 1912 by the Polish physicist Marian Smoluchowski. This involves a paddle wheel that is connected by an axle to a ratcheted gear. Both the paddle wheel and the ratchet are immersed in fluids. The system is imagined as being small enough so that the impact of a single molecule is sufficient to turn the paddle. Because of the ratchet, the paddle can only turn in one direction and therefore it appears that the Brownian motion of the paddle can be harnessed to do the work of turning the axle.

However, Feynman showed that if the two fluids were at the same temperature, collisions throughout the system would prevent this from happening. The only way work could be done, argued Feynman, is if the fluids are a different temperature, making the Brownian ratchet a heat engine.

Astronomers at the University of Iowa have determined our galaxy is surrounded by a clumpy halo of hot gases that is continually being supplied with material ejected by birthing or dying stars. The halo also may be where matter unaccounted for since the birth of the universe may reside. Photo courtesy of Christien Nielsen/Unsplash.

ETH researchers are making chocolates shimmer in rainbow colors without the addition of colorants. They have found a way to imprint a special structure on the surface of the chocolate to create a targeted color effect.

Traditional methods for coloring chocolate have been around for a long time. But the ETH researchers are able to create the rainbow effect without artificial colorants. The effect is achieved simply through a surface imprint that produces what the scientists refer to as a structural color. The process is similar to a chameleon, whose skin surface modulates and disperses light to display specific colors.

The story begins in the shared corridor of a university building. The food scientist Patrick Rühs, the materials scientist Etienne Jeoffroy and the physicist Henning Galinski chat about chocolate during their coffee break. Although they work in different research groups, their offices are next to each other. They wonder how—and whether—it might be possible to make colored chocolate. Rühs is studying the material properties of foodstuffs, Jeoffroy specializes in complex materials and Galinski has already done in-depth research into optical materials.

Homeland Security might soon have a new tool to add to its arsenal.

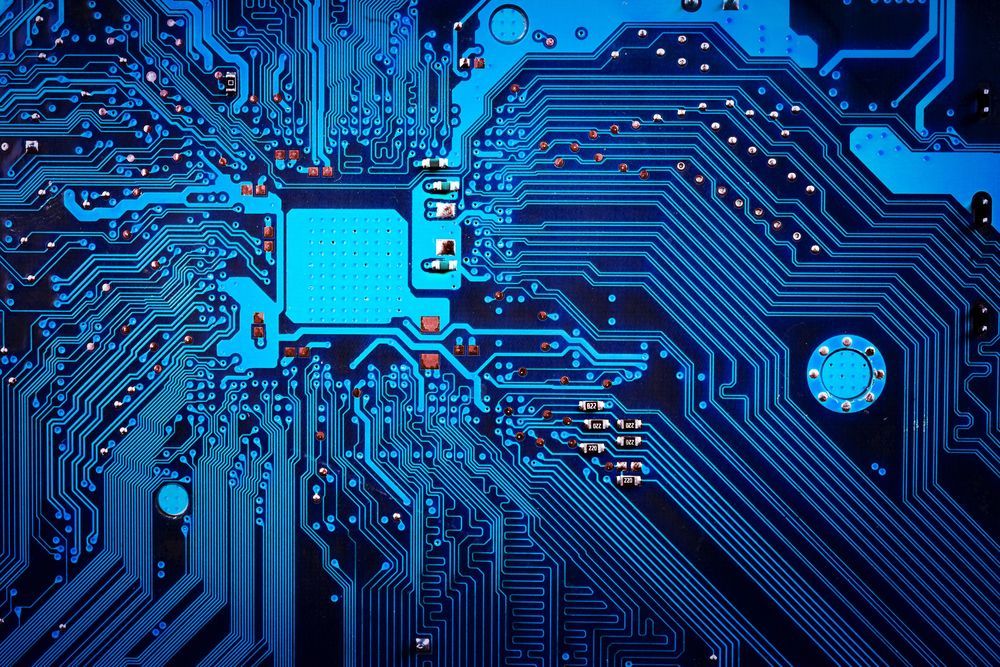

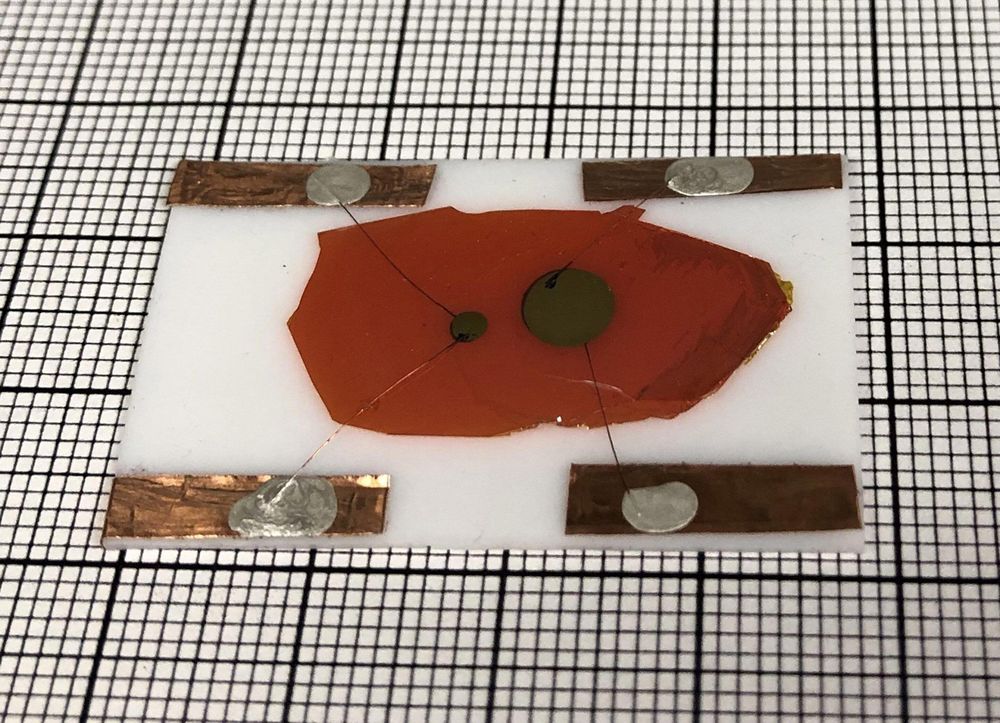

Researchers at Northwestern University and Argonne National Laboratory have developed a new material that opens doors for a new class of neutron detectors.

With the ability to sense smuggled nuclear materials, highly efficient neutron detectors are critical for national security. Currently, there are two classes of detectors which either use helium gas or flashes of light. These detectors are very large — sometimes the size of a wall.