The equivalent of as many as 1,300 plastic grocery bags per person is landing in places such as oceans and roadways, according to a new study of U.S. plastic trash.

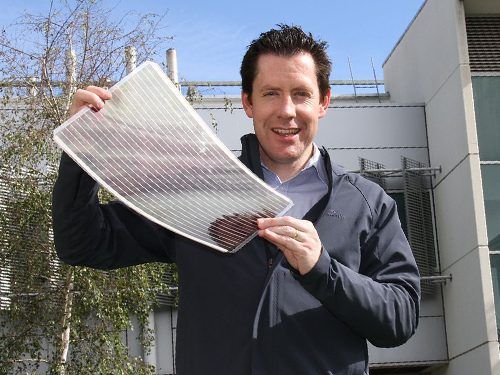

Circa 2015.

LEDs have come a long ways. From the early 70s when a bulky LED watch cost thousands of dollars to LG’s announcement last month that it had created an OLED TV as thin as a magazine, these glowing little bits of magic have become wonderfully cheap and impossibly small. But guess what: they’re about to get much smaller.

A team scientists from the University of Washington just built the world’s thinnest possible LED for use as a light source in electronics. It’s just three atoms thick. No, not three millimeters. Not three nanometers. Three atoms.

“These are 10,000 times smaller than the thickness of a human hair, yet the light they emit can be seen by standard measurement equipment,” said Jason Ross, a UW materials scientist and graduate student who helped with the research. “This is a huge leap of miniaturization of technology, and because it’s a semiconductor, you can do almost everything with it that is possible with existing, three-dimensional silicon technologies.”

Circa 2018

The world’s first-ever hiking boots to use graphene have been unveiled by The University of Manchester and British brand inov-8.

Building on the international success of their pioneering use of graphene in trail running and fitness shoes last summer, the brand is now bringing the revolutionary technology to a market recently starved of innovation.

Just one atom thick and stronger than steel, graphene has been infused into the rubber of inov-8’s new ROCLITE hiking boots, with the outsoles scientifically proven to be 50% stronger, 50% more elastic and 50% harder wearing.

Boston Dynamics announced that it has developed a robot arm for its “Spot” robot and also a charging station. Both will be available for purchase this spring.

The robot Spot made quite a splash on the internet last year, thanks to its YouTube videos. The four-legged yellow-bodied robot was shown marching its way autonomously and untethered through a wide variety of terrain in ways reminiscent of a dog; hence its name. The robot dog is available for sale. Those interested can purchase one directly from Boston Dynamics for $75,000. CEO Rob Playter told members of the press recently that the company has sold 260 of the robots as of last June. Those robots are currently being tested (and in some cases, used) in mining, healthcare, construction and other sectors—mostly in situations that are dangerous for people. The company has also created a host of add-ons for the robot to assist in a wide variety of applications. The company is now adding to that list by making available both a robot arm and a charging station.

The robot arm affixes to the top front of Spot, resembling a long neck with an articulated joint. A gripper is mounted on the end of the arm, vaguely reminiscent of a head with a mouth. The robot arm is capable of six degrees of motion and comes with its own user interface (UI). The arm can be programmed ahead of time to carry out tasks, such as using doorknobs, turning hand cranks, or lifting, carrying and moving materials. Alternatively, the arm can be controlled by a user watching the action. The arm is programmable via an associated developer API toolkit.

Scientists have created a super white paint that is the yin to Vantablack’s yang.

While ultra black materials can today absorb more than 99.96 percent of sunlight, this new super white coat can reflect 95.5 percent of all the photons that hit it.

Instead of warming up under direct light, objects painted with this new acrylic material can remain cooler than their surrounding temperature even under the Sun, which could allow for a new energy-efficient way to control temperature inside buildings.

Circa 2019

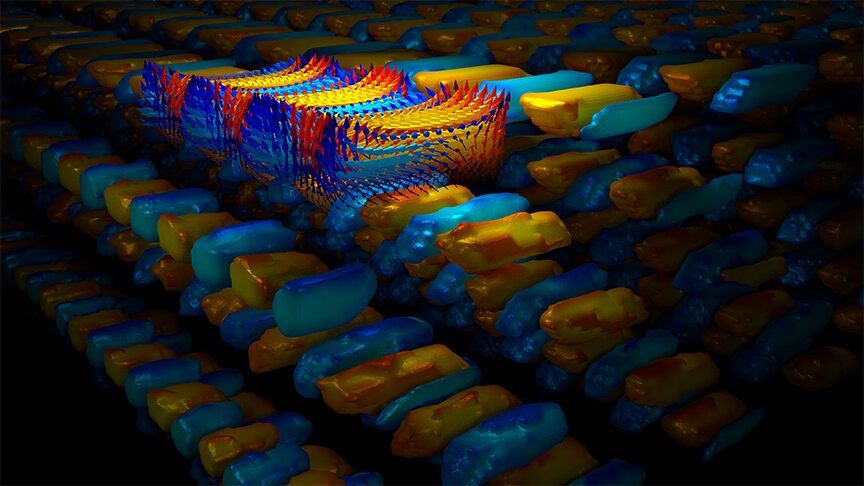

“Frustration” plus a pulse of laser light resulted in a stable “supercrystal” created by a team of researchers led by Penn State and Argonne National Laboratory, together with University of California, Berkeley, and two other national laboratories.

This is one of the first examples of a new state of matter with long-term stability transfigured by the energy from a sub-pico-second laser pulse. The team’s goal, supported by the Department of Energy, is to discover interesting states of matter with unusual properties that do not exist in equilibrium in nature.

“We are looking for hidden states of matter by taking the matter out of its comfortable state, which we call the ground state,” says the Penn State team leader Venkatraman Gopalan, professor of materials science. “We do this by exciting the electrons into a higher state using a photon, and then watching as the material falls back to its normal state. The idea is that in the excited state, or in a state it passes through for the blink of an eye on the way to the ground state, we will find properties that we would desire to have, such as new forms of polar, magnetic and electronic states.”

Photos of touching down on an asteroid.

On Tuesday, October 20th, NASA made history when the OSIRIS-REx mission successfully completed a “touch-and-go” sample collection maneuver with asteroid 101955 Bennu over 200 million miles away from Earth. And now, we have the timelapse to prove it.

NASA shared a total of 82 images from spacecraft’s SamCam imager covering the approach, the touchdown at sample sight Nightingale, and the “back-away burn.” The slideshow was captured over the course of approximately five minutes, and covers everything from about 82 feet (25 meters) above the asteroid, through the back-away burn, and up until the craft achieved an altitude of approximately 43 feet (13 meters), kicking up a lot of material along the way.