Researchers have shown how to effectively transform one material into another using a finely shaped laser pulse.

All Hands

The new enzyme can make its way through plastic six times faster than the previous plastic-devouring enzyme developed by members of the same team, according to research published Monday in the journal PNAS.

“We were actually quite surprised it worked so well,” McGeehan told CNN, though he added that the enzyme is “still way too slow” to be helpful at any meaningful scale.

Andy takes a closer look at one of his favourite demos from the 2012 Christmas Lectures, bringing together a levitating superconductor and a bewildering Möbius strip made from over 2,000 magnets.

We’d love it if you helped us translate this video: https://www.youtube.com/timedtext_video?v=zPqEEZa2Gis

As his super-conducting boat whizzes along the track, Andy demonstrates the remarkable properties of the superconducting material (Yttrium barium copper oxide) which allows it to seemingly float both above and below the track.

Subscribe for regular science videos: http://bit.ly/RiSubscRibe

The Ri is on Twitter: http://twitter.com/ri_science

and Facebook: http://www.facebook.com/royalinstitution

and Tumblr: http://ri-science.tumblr.com/

Our editorial policy: http://www.rigb.org/home/editorial-policy

Subscribe for the latest science videos: http://bit.ly/RiNewsletter

The following is adapted from Lewis’ The Rise: Creativity, the Gift of Failure, and the Search for Mastery, published by Simon & Schuster.

“It says, ‘No entrance,’ but you just enter,” physicist Andre Geim told me about the graphite mines in the mountains where he often hikes. His comment embodied the insouciance behind his Nobel Prize–winning physics experiment and his habit of experimenting deliberately outside of his area of expertise.

Geim, a Russian-born Dutch and British citizen and a professor at the University of Manchester, and his colleague Konstantin Novoselov won the 2010 Nobel Prize in physics for their experiments involving the single-atom-thick material called graphene—the thinnest, strongest, most conductive material in existence. It is predicted to replace silicon and transform the electronics industry as we know it.

Using superconductors, scientists can levitate small creatures such as fruit flies for long periods of time.

Scientists who want to study the effects of weightlessness have always had precious few options. There’s the “vomit comet,” NASA’s Weightless Wonder plane that creates a few seconds of weightlessness during parabolic flights. Or they could convince the space agency to actually launch their experiments into the great beyond.

But there might be an easier and cheaper way: levitation.

In a recent study, physicist Richard Hill and colleagues used superconductive magnets to levitate fruit flies for an extended period of time, allowing them to study the long-term effects of weightlessness on the insects’ biology. A fruit fly is a far cry from a human, but studying insects in weightlessness here on Earth is much cheaper than doing so inside a satellite 220 miles away in space, and even fruit flies could tell scientists something about how humans and their DNA will react to long-duration spaceflight.

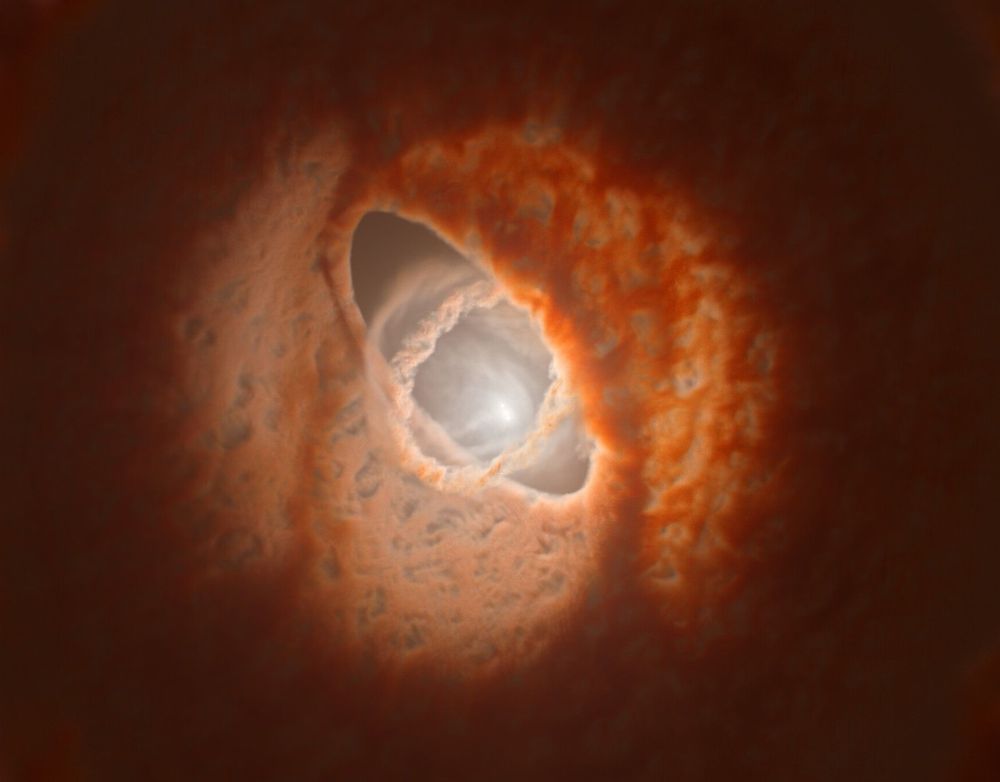

Disc is left with warped and tilted rings.

The young triple star system GW Orionis appears to be surrounded by a ring of gas and dust that has torn away and become misaligned with the rest of the system’s circumstellar disc. That is the conclusion of an international team of astronomers led by Stefan Kraus at the University of Exeter – who combined observations with numerical simulations to identify disc structures that have been confined to theory until now.

Astronomers believe that most stars are born with one or more companions, which interact in complex ways with the disc of planet-forming gas and dust surrounding the stellar system. If this disc is misaligned with the orbital planes of the host stars, previous simulations have predicted that it will warp and tear under their gravitational torque, forming distinct rings in separate planes from the rest of the disc. So far, however, astronomers have yet to identify this tearing in their observations of misaligned discs.

In their study, Kraus’ team aimed to verify this tearing process by making detailed observations of the triple star system, GW Orionis. At just around 1 million years old, the system’s circumstellar disc has yet to collapse to form planets; while at its centre, the orbital planes of its three stars are highly misaligned with each other. Over 11 years beginning in 2008, the researchers used the Very Large Telescope (VLT) and Atacama Large Millimeter Array (ALMA) telescopes in Chile to measure thermal emissions and scattered visible light originating from the system. This allowed them to map the distribution of material in the disc.

Though the Summer Olympics were postponed, there’s at least one place to see agile hurdlers go for the gold.

You just need a way to view these electron games.

Using a novel optical detection system, researchers at Rice University found that electricity generated by temperature differences doesn’t appear to be affected measurably by grain boundaries placed in its way in nanoscale gold wires, while strain and other defects in the material can change this “thermoelectric” response.

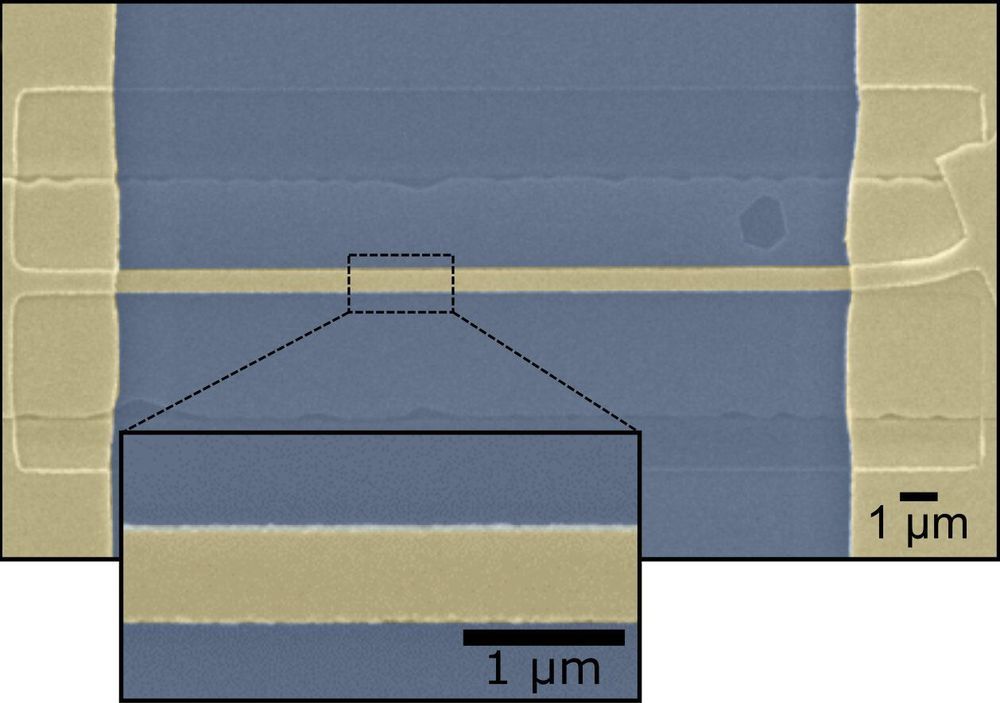

Over the past few decades, researchers have identified a number of superconducting materials with atypical properties, known as unconventional superconductors. Many of these superconductors share the same anomalous charge transport properties and are thus collectively characterized as “strange metals.”

Researchers at the University of California, Berkeley (UC Berkeley) and Los Alamos National Laboratory have been investigating the anomalous transport properties of strange metals, along with several other teams worldwide. In a recent paper published in Nature Physics, they showed that in one of these materials, BaFe2(As1− xPx)2, superconductivity and quantum criticality are linked by what is known as the Hall effect.

For decades, physicists have been unable to fully understand T-linear resistivity, a signature of strange metals that has often been observed in many unconventional superconductors. In 2016, the team at UC Berkeley and Los Alamos National Lab observed an unusual scaling relationship between the magnetic field and temperature in superconductor BaFe2(As1− xPx)2.

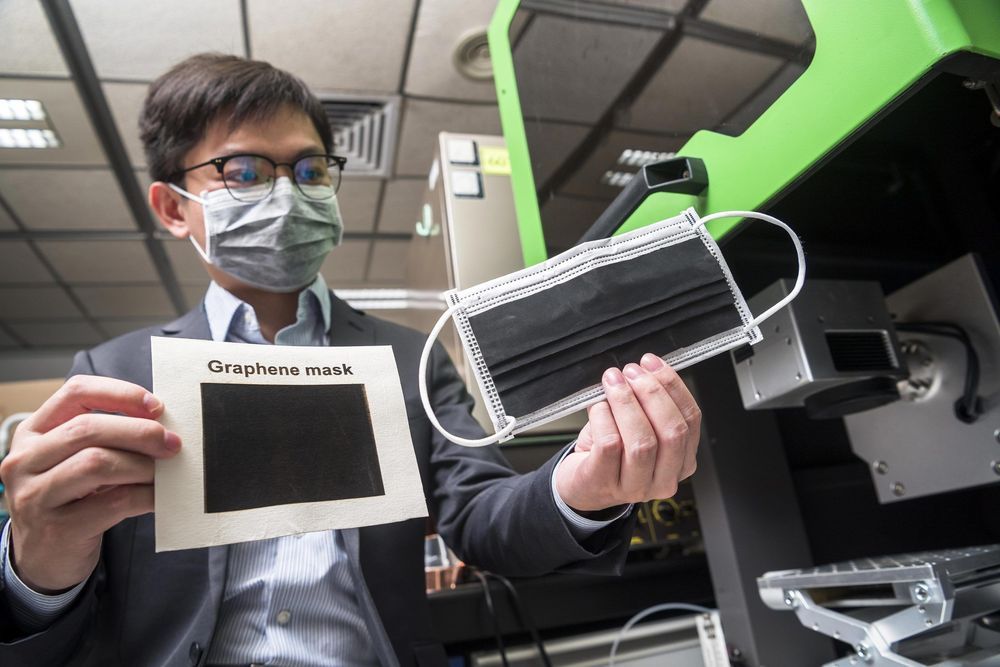

Anti-bacterial efficiency close to 100% under 10-min sunlight and promising results in deactivation of coronaviruses.

Face masks have become an important tool in fighting against the COVID-19 pandemic. However, improper use or disposal of masks may lead to “secondary transmission.” A research team from City University of Hong Kong (CityU) has successfully produced graphene masks with an anti-bacterial efficiency of 80%, which can be enhanced to almost 100% with exposure to sunlight for around 10 minutes. Initial tests also showed very promising results in the deactivation of two species of coronaviruses. The graphene masks are easily produced at low cost, and can help to resolve the problems of sourcing raw materials and disposing of non-biodegradable masks.

The research is conducted by Dr. Ye Ruquan, Assistant Professor from CityU’s Department of Chemistry, in collaboration with other researchers. The findings were published in the scientific journal ACS Nano, titled “Self-Reporting and Photothermally Enhanced Rapid Bacterial Killing on a Laser-Induced Graphene Mask.”