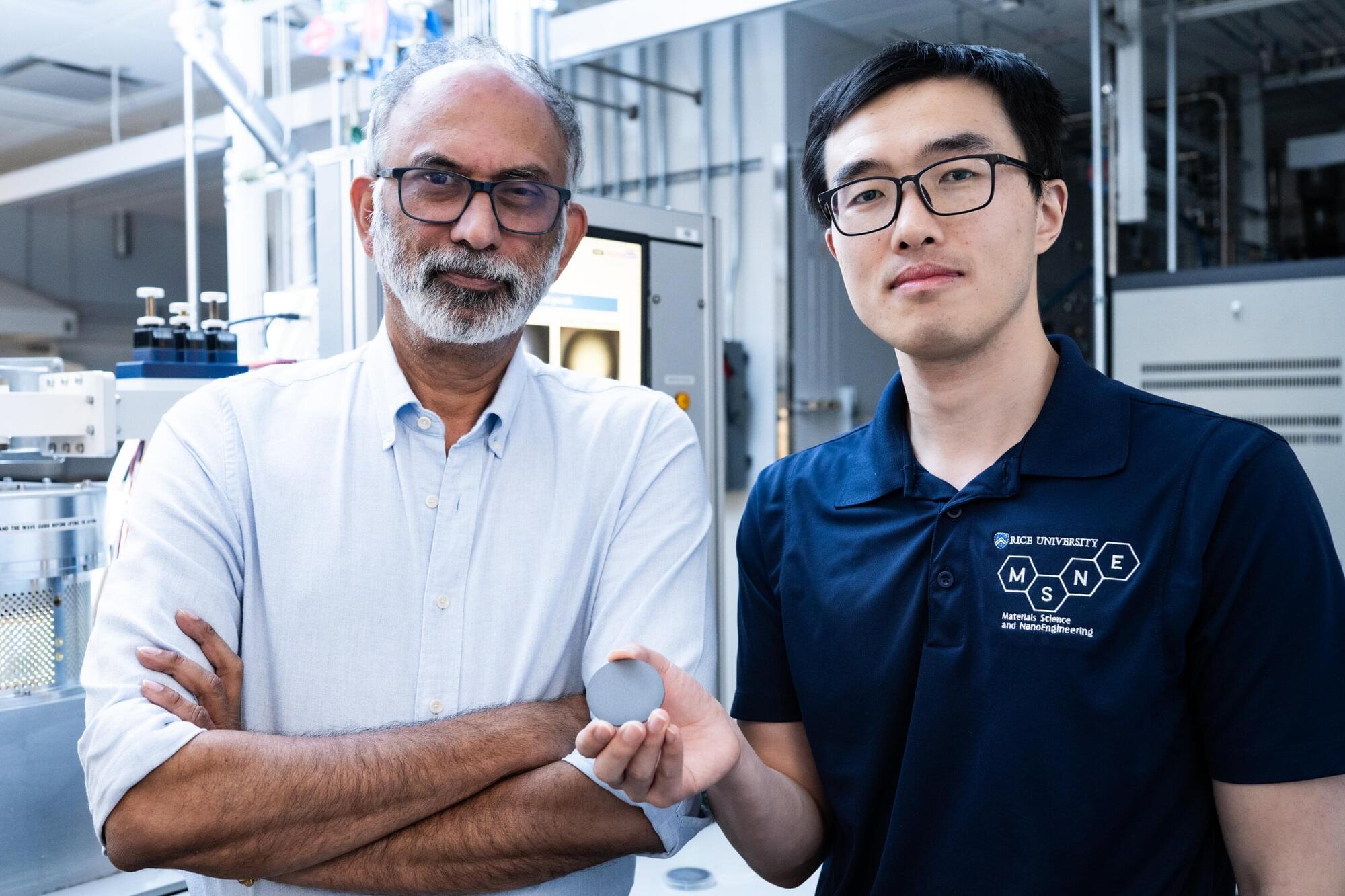

A collaboration between the groups of Professor Mónica H. Pérez-Temprano at the Institute of Chemical Research of Catalonia (ICIQ) and Professor Anat Milo at Ben-Gurion University of the Negev has uncovered how the characteristics of specific substrates require certain reaction conditions that determine the course of a chemical reaction, in the context of C–H deuteration reactions.

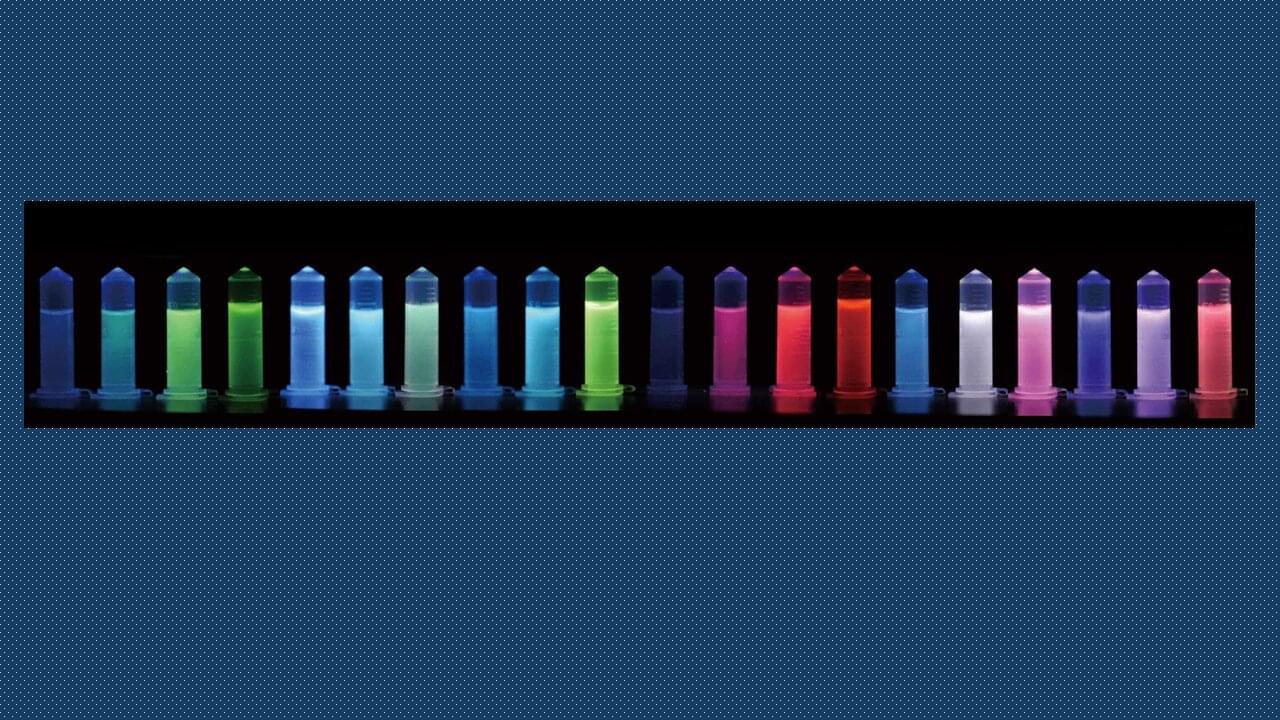

The study, published in Nature Catalysis, combines detailed experiments with data science rooted in reaction intermediates. By correlating molecular features with reaction outcomes, the researchers reveal that the choice of deuterium source—such as heavy water (D2O), deuterated methanol (CD3OD), or acetic acid-d4 (AcOD-d4)—does more than merely influencing the degree of deuterium incorporation. It can actively alter the reaction pathway, revealing hidden mechanistic complexity that intuition alone could not predict.