“The toughness of this material near liquid helium temperatures (20 kelvin, −253°C) is as high as 500 megapascals square root metres,” said Robert Ritchie, Professor of Mechanical Engineering at Berkeley and study co-author. “In the same units, the toughness of a piece of silicon is one, the aluminium airframe in passenger airplanes is about 35, and the toughness of some of the best steels is around 100. So, 500, it’s a staggering number.”

The team’s new findings, alongside other recent work on HEAs, may force the materials science community to reconsider long-held notions about how physical characteristics give rise to performance.

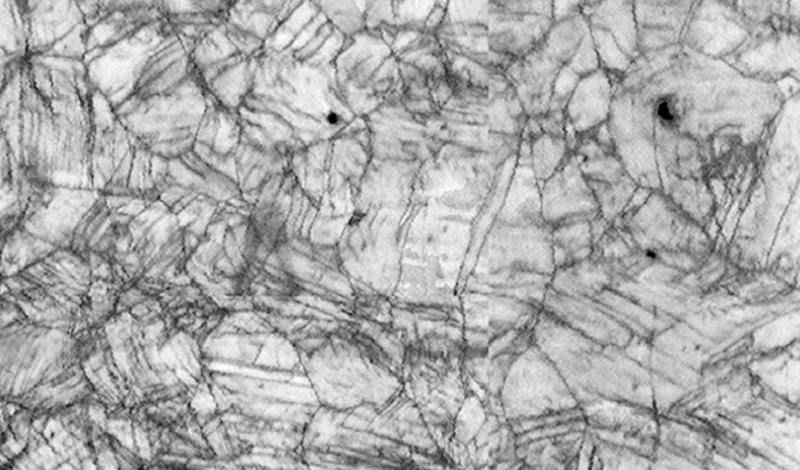

“It’s amusing, because metallurgists say that the structure of a material defines its properties, but the structure of the CrCoNi is the simplest you can imagine – it’s just grains,” explained Ritchie.