Photovoltaics (PVs), technological systems that can convert sunlight into electricity are among the most promising and widely adopted clean energy solutions worldwide. While existing silicon-based solar cells have already achieved remarkable performances, energy engineers have been working to develop other photovoltaic technologies that could be even more durable, efficient and affordable.

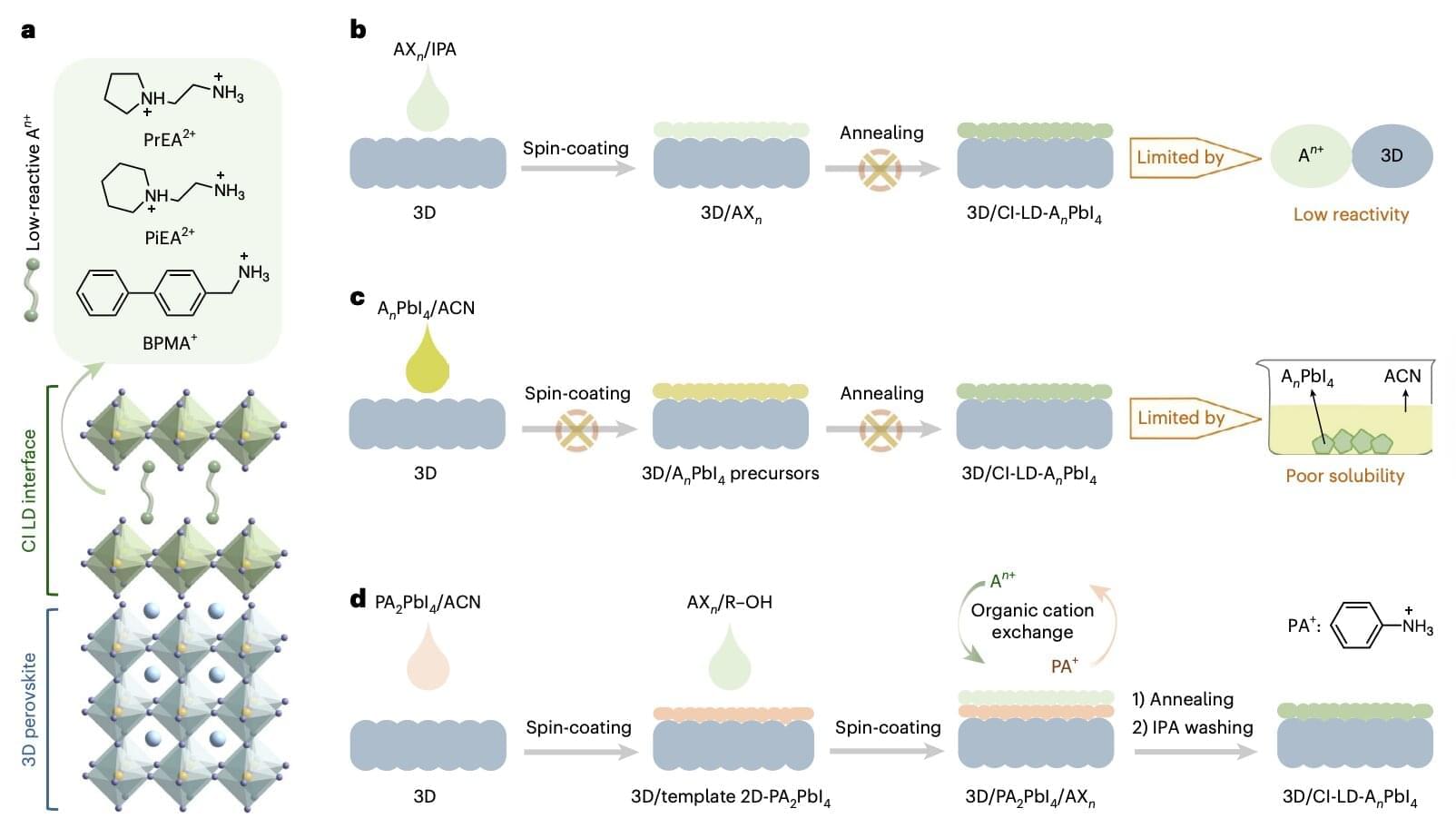

An emerging type of solar cells that could be manufactured at a lower cost, while still retaining good efficiencies, are those based on a class of materials with a characteristic arrangement of atoms, known as perovskites. These cells, known as perovskite solar cells (PSCs), have been found to attain high power conversion efficiencies and are based on materials that could be easier to synthesize when compared to silicon wafers.

Despite their potential, PSCs still face considerable limitations that have so far prevented their widespread deployment and commercialization. Most notably, improving the efficiency of these cells has been found to adversely impact their stability over time, and vice versa.