A new method to recycle wind turbine blades without using harsh chemicals resulted in the recovery of high-strength glass fibers and resins that allowed Washington State University researchers to repurpose the materials to create stronger plastics.

The innovation provides a simple and environmentally friendly way to recycle wind turbine blades to create useful products.

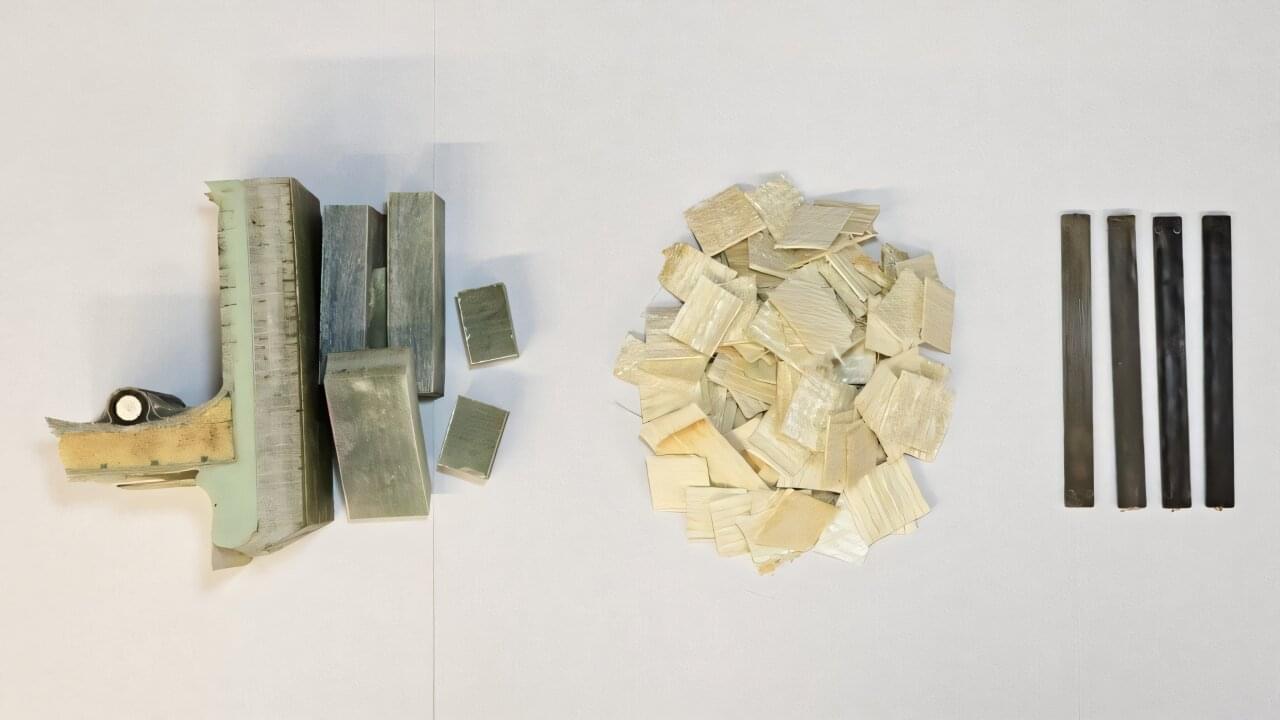

Reporting in the journal, Resource, Conservation, and Recycling, the team of researchers cut the lightweight material that is commonly used in wind turbine blades, called glass fiber-reinforced polymer (GFRP), into approximately two inch-sized blocks. They then soaked the flakes in a bath of low-toxicity organic salt in pressurized, superheated water for about two hours to break down the material. They then repurposed its components to make stronger plastics.