With the right technology, solar energy has the potential to meet all of the world’s electricity needs, but we are still a long way off from that point. Still, governments around the world are setting high objectives for renewable energy. Many world leaders have set commitments to phase out coal power and transition away from fossil fuels, and solar panel installations are currently one of the top contenders for implementing these plans.

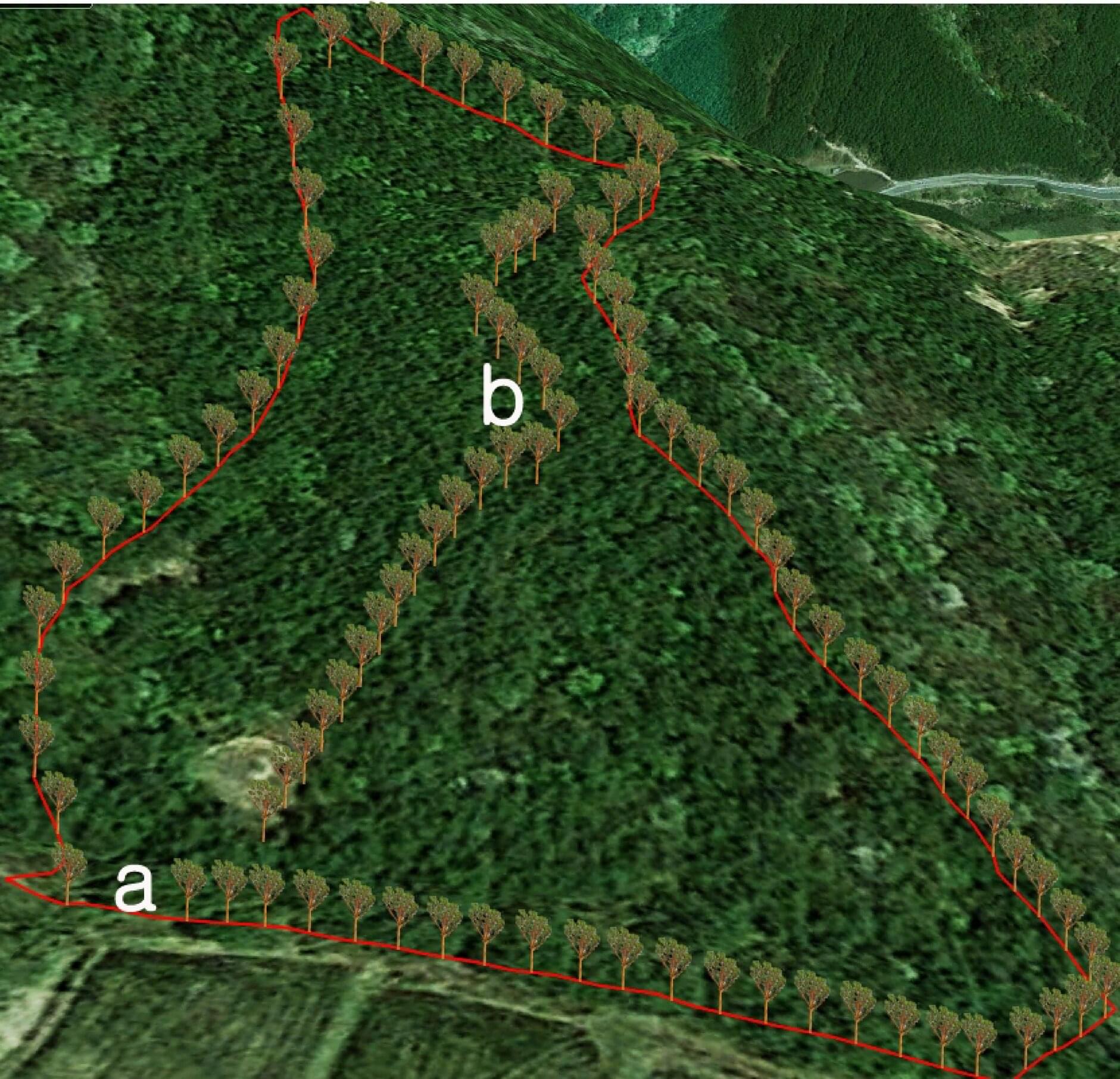

However, solar energy has a bit of a dark secret. In some places, putting up these massive solar panel installations requires cutting down hundreds or even thousands of hectares of forests over time. In South Korea, deforestation caused by solar installations affected 529 hectares of forest in 2016, 1,435 hectares in 2017, and 2,443 hectares in 2018.

Of course, there are some solar installations located in deserts or other treeless landscapes that don’t have this issue. But those that do end up cutting out an incredibly important carbon sink, first worsening the problem they are attempting to alleviate. This deforestation then causes further issues with erosion and the destruction of natural habitats.