https://paper.li/e-1437691924#/

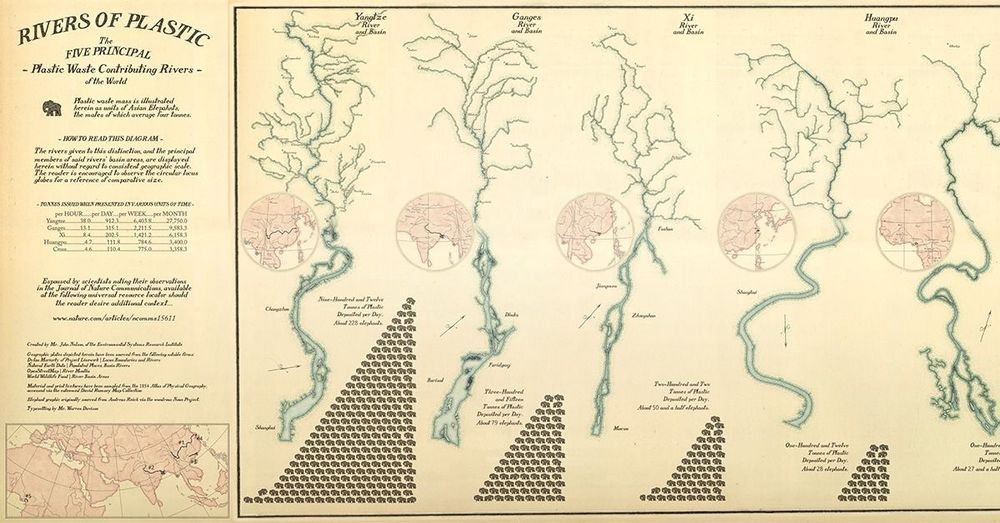

Every year, 8 million metric tons of plastic enters the world’s oceans – much of it through our river systems. See which rivers are polluting the most.

https://paper.li/e-1437691924#/

Every year, 8 million metric tons of plastic enters the world’s oceans – much of it through our river systems. See which rivers are polluting the most.

In the search for people working on cheaper supercapacitors, she found herself in the lab of Noureen Siraj, Ph.D., an assistant professor of chemistry at the University of Arkansas, Little Rock. One of Siraj’s students, Samantha Macchi, had already been working on such a project for about a year and a half, figuring out how to make supercapacitor electrodes from common materials like used tea leaves, molasses, and a basic kitchen microwave oven — humble beginnings for a high-tech device. Siraj and Macchi brought Bollimpalli onto the project to learn about the work, which she later presented at ISEF. Meanwhile, Macchi and Siraj published the resulting research in January in the journal Chemistry Select.

Bollimpalli was initially assigned to a different project in the lab, but when she found out about the work on supercapacitors, she asked to switch tasks. Siraj, who is used to having high school students learn about her team’s work, quickly obliged.

“She quickly learned all the protocols, and she actually was able to explain. She brought an understanding that is missing in a lot of the high school students,” Siraj tells Inverse. “She really is good at absorbing the information.” They worked together tirelessly to help Bollimpalli nail the presentation she would later give at ISEF.

Building cracks and deterioration are common points of concern for asset owners and managers alike, but a new technology may soon alleviate these industry issues.

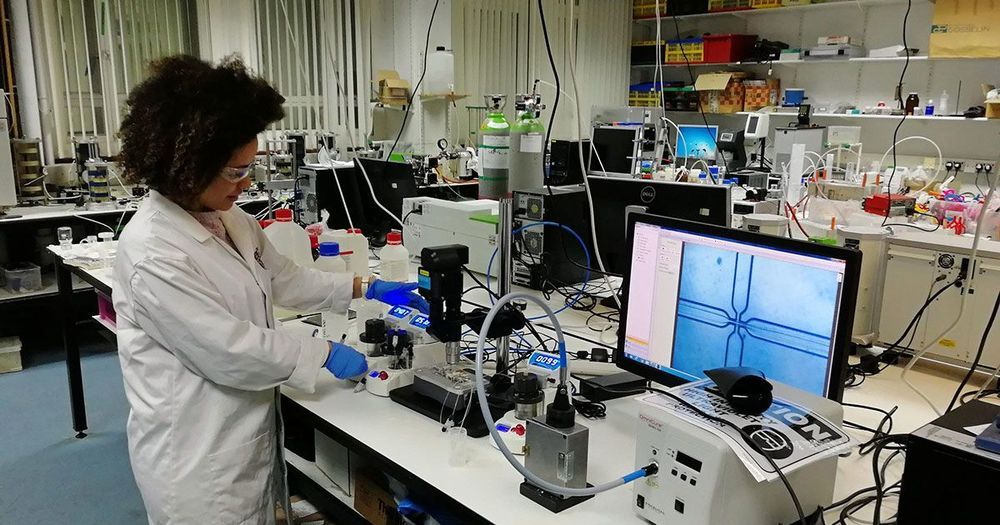

Researchers at the University of Cambridge are using micro-encapsulation technologies developed by Dolomite Microfluidics to develop self-healing construction materials.

The university’s Department of Engineering’s Geotechnical and Environmental Research Group said last month that it is developing microcapsules containing ‘healing’ agents such as minerals, epoxy, or polyurethane which can be added to building materials to allow the self-repair of small cracks that develop over time.

Illinois researchers have introduced a new cutting-edge reusable adhesive that activates in seconds, works underwater, and is strong enough to deadlift 11 pounds: shape memory polymers (SMPs).

The team—associate professor in mechanical science and engineering Seok Kim, graduate student Jun Kyu Park, and former graduate student Jeffrey D. Eisenhaure (Ph. D. ME ‘17, now with Northrop Grumman)—has proved that SMPs can retain dry adhesion properties while submerged. Their study, “Reversible underwater dry adhesion of a shape memory polymer,” was recently published by the scientific journal Advanced Materials Interfaces.

Classified as a smart material, SMPs have the ability to manually transition between their original state and a deformed state. By manipulating the state of their SMPs, Kim and his team achieved successful adhesion to surfaces submerged in water as well as other liquid media such as oil.

I have heard the term Sh… Bricks, but never thought I would live the day to hear it literally. Waste is an issue, and a growing global population will create more waste, and it needs to be addressed. The supply of waste is endless. People who find innovatiive ways to use it as a raw material will prosper Once sewage is drained of water, treated, and dried – what the heck do you do with it? Well, some of it ends up as fertiliser, but a massive 30 percent of our poop leftovers is sent to landfill to rot, or just sits in storage. What a waste.

Especially when, according to researchers from Australia’s RMIT University, using these ‘biosolids’ in bricks could be a surprisingly effective way of repurposing all that former sludge.

A concrete or steel wall along the southern border of the U.S. is not impenetrable; daily news programs show how concrete walls are burrowed under or driven over with car carriers and hydraulic ramps, while steel walls are breached with grappling hooks and inexpensive metal saws. And while a fiber-optic fence is also vulnerable to a physical cut, it can be discretely buried or placed along existing infrastructure, and (unlike concrete or steel) can fundamentally detect the location of a cut with high accuracy so that border patrol agents can be dispatched to understand the breach and apprehend the humans (easily distinguished from animals) crossing over the fence.

Let’s put our money and photonics technology to more effective use.

Saint Jean Carbon has announced that it is developing a new form of graphene battery technology and will start building the first prototype of its graphene gel salt water batteries. Batteries based on this technology should charge faster, run longer and theoretically may last indefinitely. The project’s long term goal is to have a series of three full production batteries ready for launch in spring 2020.

Saint Jean Carbon stated that salt water battery technology has been in research for about 5 years. Continued advancement slowed due to limited voltage capacity in comparison with Lithium batteries. Now with the use of graphene in a highly concentrated salt water gel, graphene can now be used without worrying about the graphene re-stacking, which would reduce the intercalation rate. Salt water batteries are much safer, won’t burn and have significantly less raw material cost.

The Company plans on building a “flex” production line that will allow a number of companies to share in the facility on a fee for use basis. The Company’s first production will concentrate on three specific battery types:

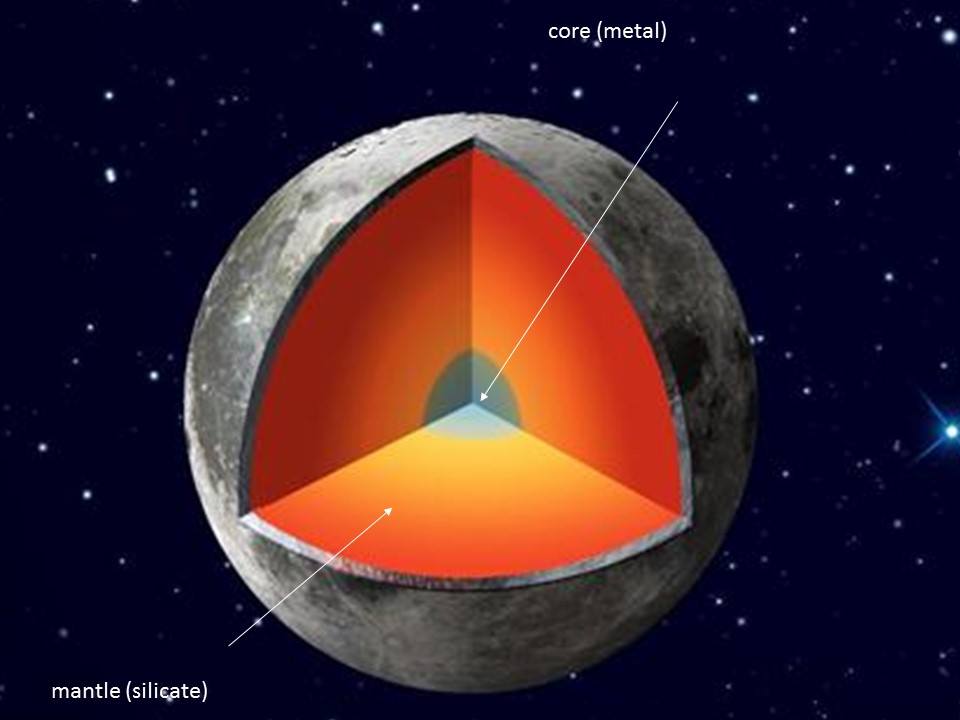

Plans for a European base on the moon have taken a major step forward.

The European Space Agency revealed it has signed up rocket maker ArianeGroup to develop plans for a moon base that could be used to mine material from the lunar surface.

The project will ‘examine the possibility of going to the Moon before 2025 and starting to work there’ — and could trigger a new space race as countries rush to harness lunar resources.