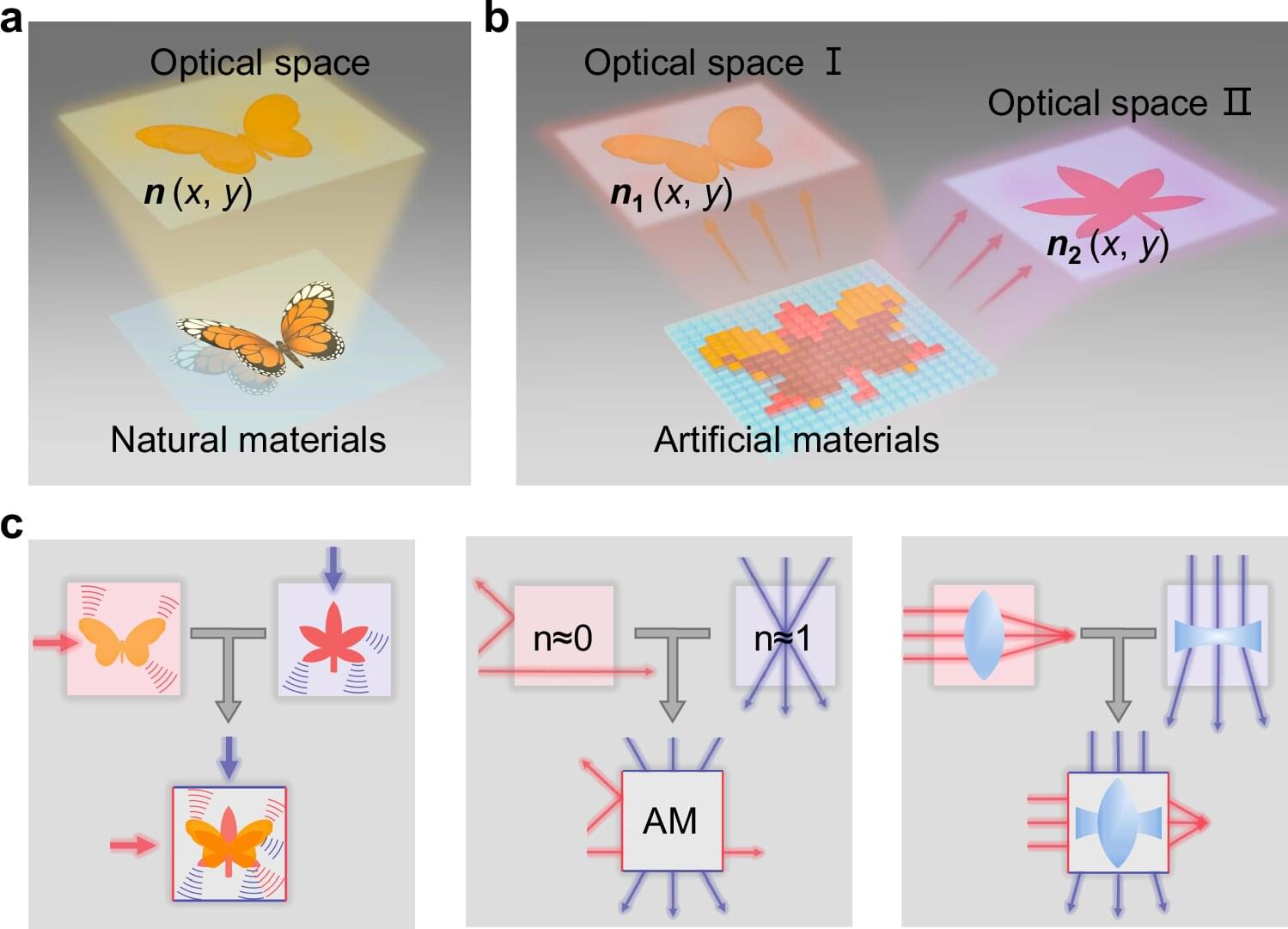

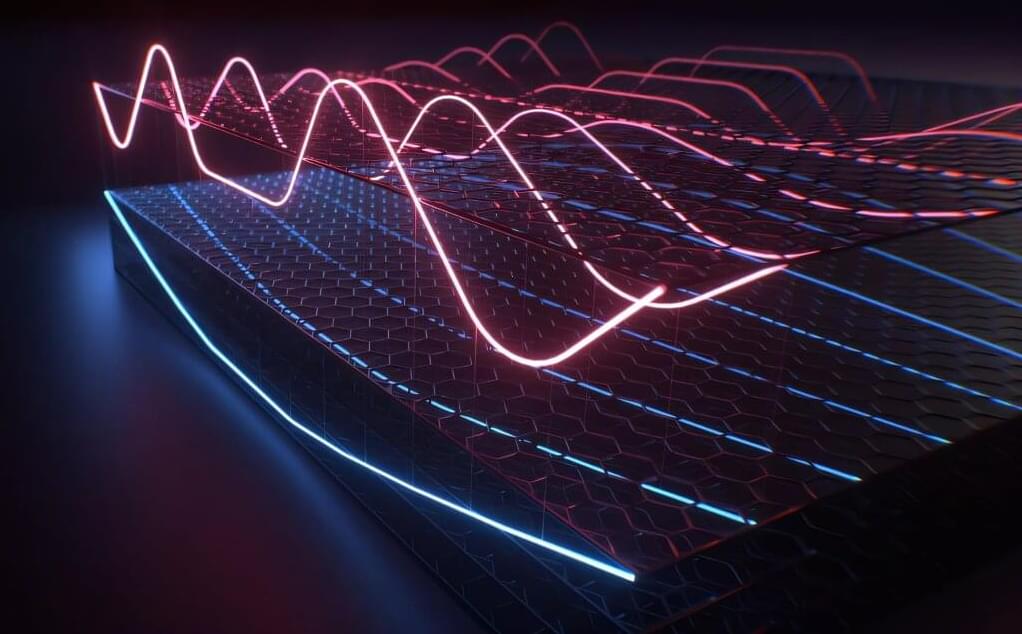

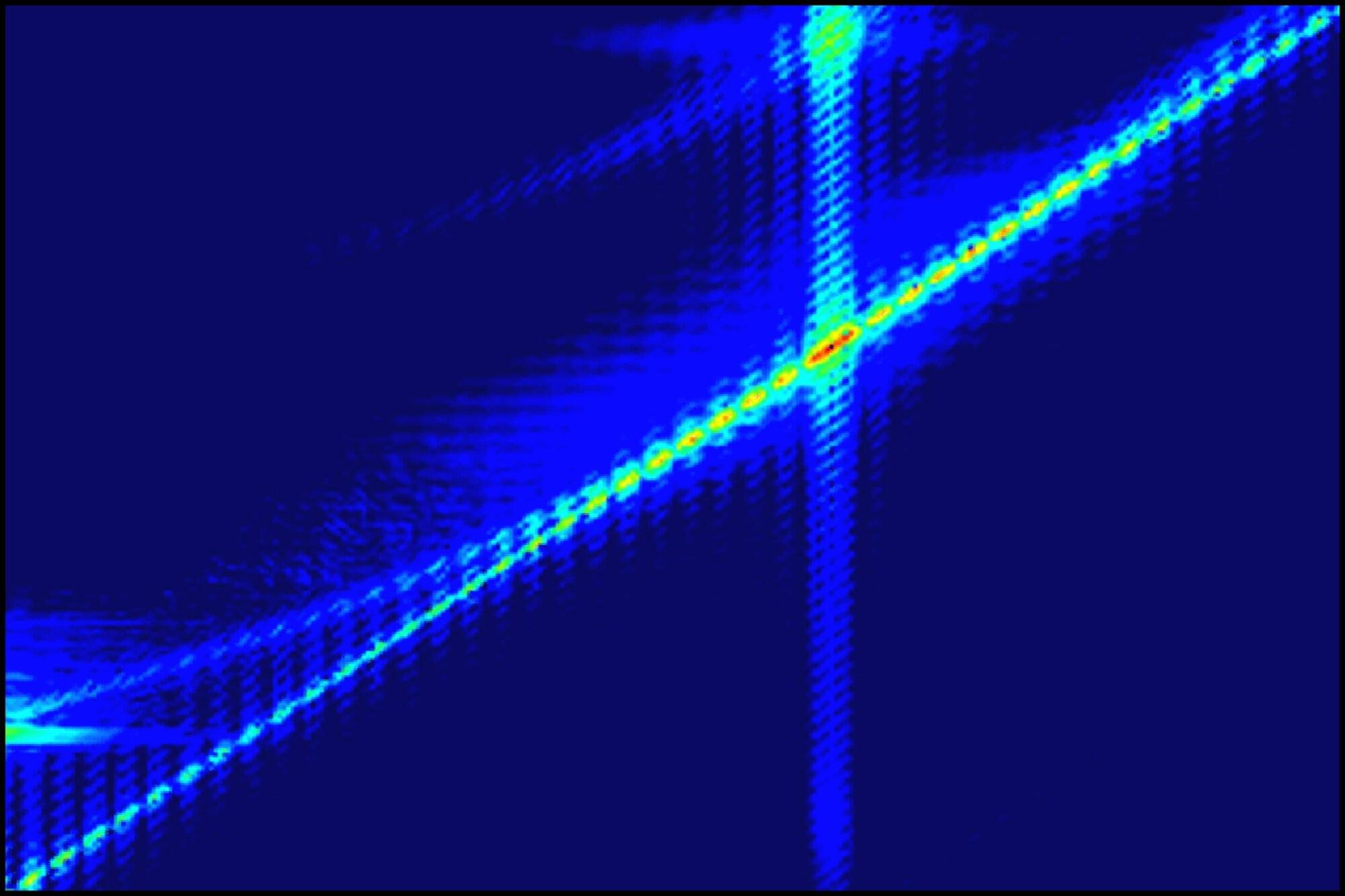

Researchers have harnessed nonlocal artificial materials to create optical systems that emulate parallel spaces, wormholes, and multiple realities. A single material acts as two distinct optical media or devices simultaneously, allowing light to experience different properties based on entry boundaries. Demonstrations include invisible optical tunnels and coexisting optical devices, opening new avenues for compact, multifunctional optical devices by introducing nonlocality as a new degree of freedom for light manipulation.

What if a single space could occupy two different objects at once, depending on how photons access this space? Scientists have brought this sci-fi concept to life, creating optical systems that mimic the exotic phenomena of parallel universes and wormholes.

In a study published in Nature Communications, researchers in China used nonlocal artificial materials to develop “photonic parallel spaces.”