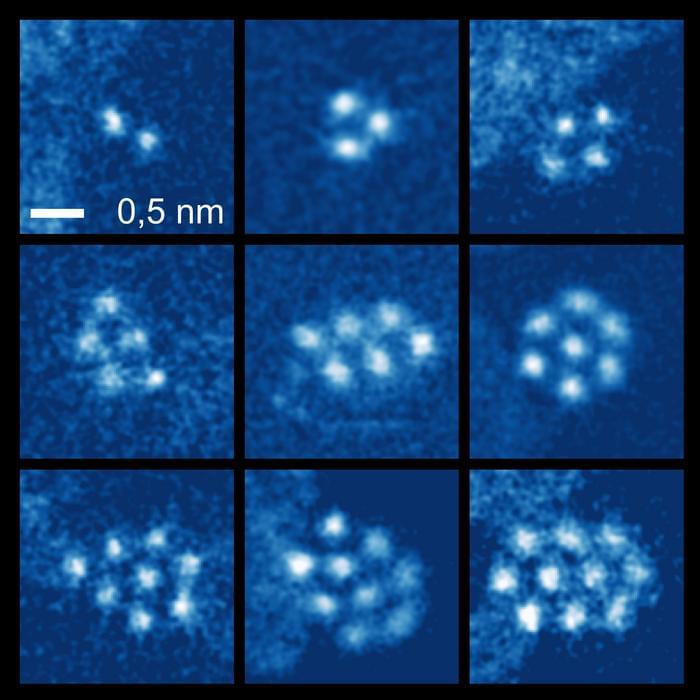

Just like a book can’t be judged by its cover, a material can’t always be judged by its surface. But, for an elusive conjectured class of materials, physicists have now shown that the surface previously thought to be “featureless” holds an unmistakable signature that could lead to the first definitive observation.

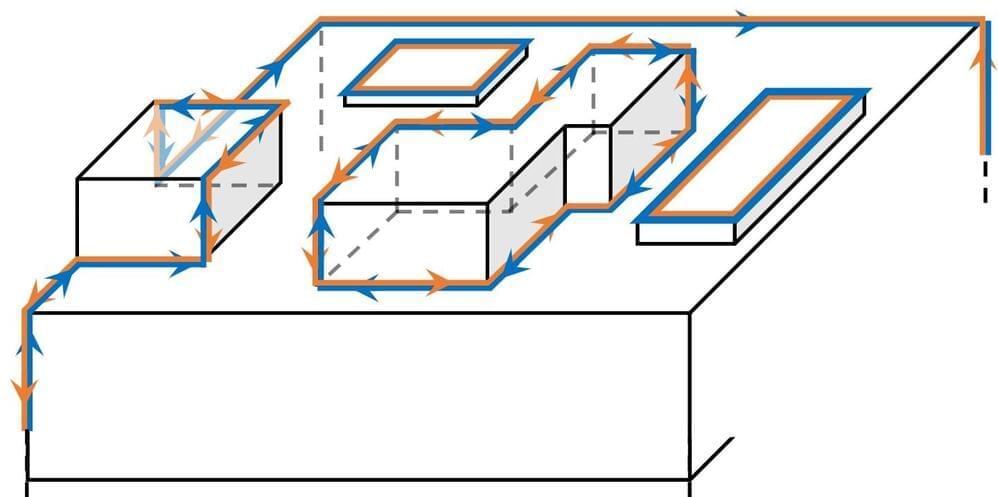

Higher-order topological insulators, or HOTIs, have attracted attention for their ability to conduct electricity along one-dimensional lines on their surfaces, but this property is quite difficult to experimentally distinguish from other effects. By instead studying the interiors of these materials from a different perspective, a team of physicists has identified a surface signature that is unique to HOTIs that can determine how light reflects from their surfaces.

As the team reports in the journal Nature Communications, this property could be used to experimentally confirm the existence of such topological states in real materials.