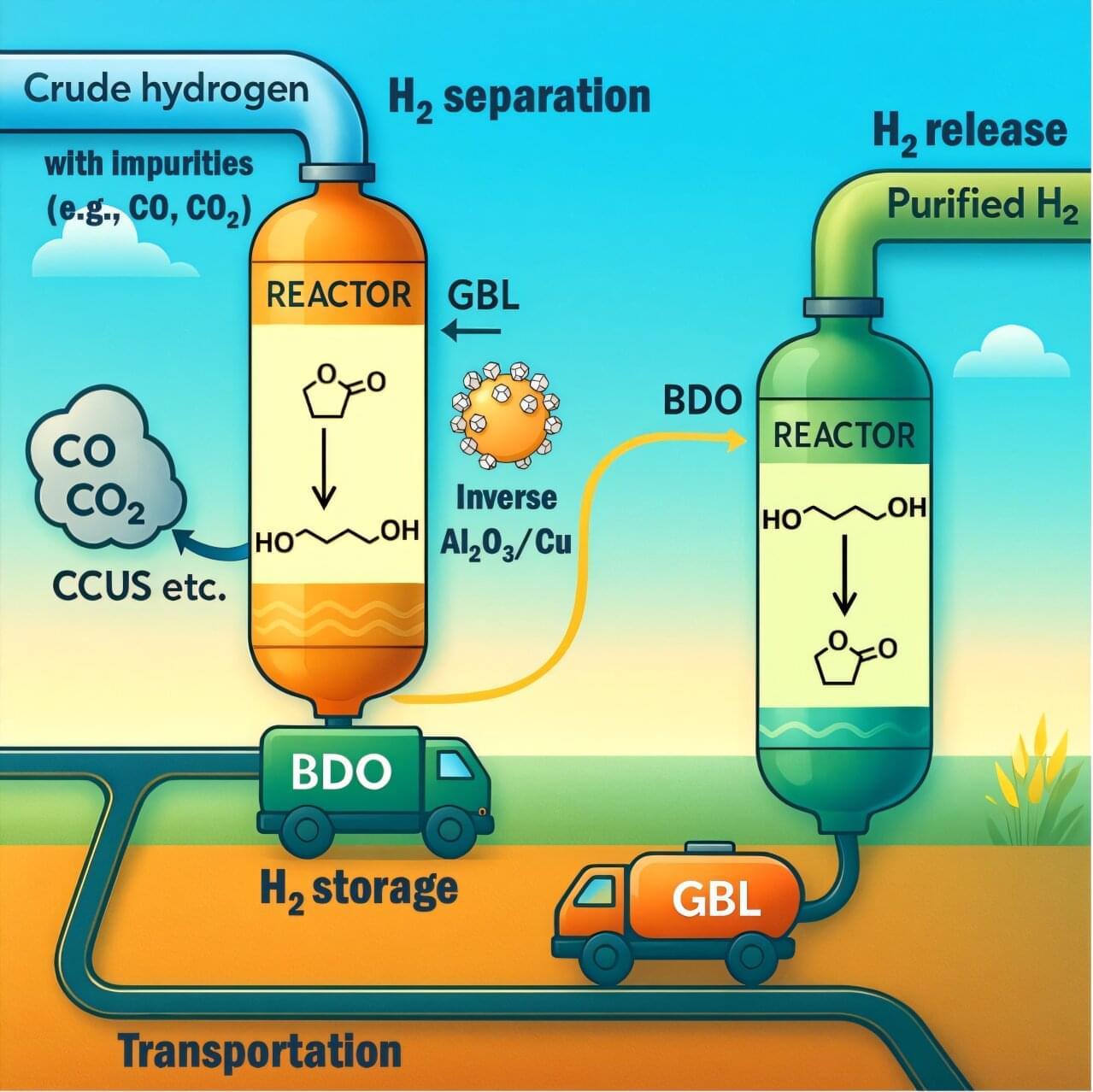

Hydrogen (H2) is an Earth-abundant molecule that is widely used in industrial settings and could soon contribute to the clean generation and storage of electricity. Most notably, it can be used to generate electricity in fuel cells, which could in turn power heavy-duty vehicles or serve as back-up energy systems.

Despite its potential for various real-world applications, hydrogen is often expensive to produce, store and safely transport to desired locations. Moreover, before it can be used, it typically needs to be purified, as hydrogen produced industrially is typically mixed with other gases, such as carbon monoxide (CO), carbon dioxide (CO₂), nitrogen (N₂) and light hydrocarbons.

Researchers at Fudan University and other institutes in China recently devised a new strategy to separate hydrogen from impurities at low temperatures, while also enabling its safe storage and transportation. Their proposed method, outlined in a paper published in Nature Energy, relies on a reversible chemical reaction between two organic compounds that act as hydrogen carriers, enabling the reversible absorption and release of hydrogen.