Brave new world let’s create happiness for everyone by putting microelectrode arrays in our brains but be careful not to create a situation like death by ecstacy by Larry Niven.

In the brain, pleasure is generated by a handful of brain regions called, “hedonic hotspots.” If you were to stimulate these regions directly, you would likely feel pleasurable sensations. However, not all of the hedonic hotspots are the same–some generate the raw sensations of pleasure whereas others are responsible for consciously interpreting and elaborating on the raw pleasure produced by the other hotspots. In this video, in addition to exploring the neuroscience of pleasure, we’ll see how understanding pleasure, happiness, meaning, and purpose can help us live better lives.

Follow @senseofmindshow for more neuroscience explainers.

Follow on Social Media: https://linktr.ee/senseofmind.

-

Chapters.

00:00 Hedonic hotspots: the brain’s pleasure generators.

00:56 The evolution of pleasure.

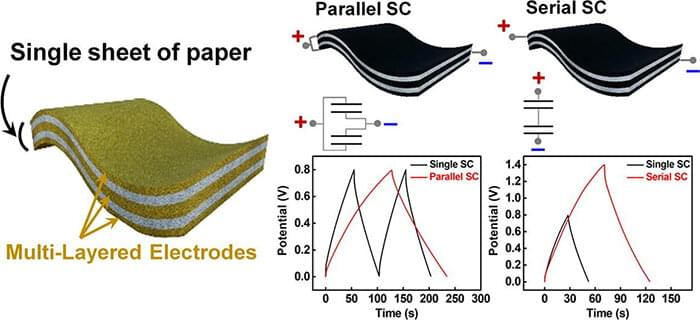

01:46 How the brain generates pleasure.

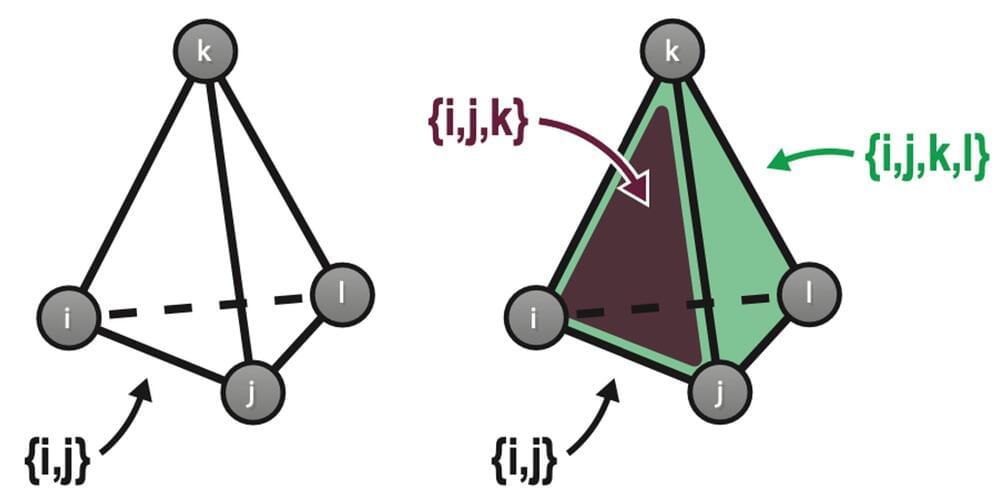

03:07 The subcortical (‘core’) pleasure network.

04:08 The cortical (‘higher’) pleasure network.

05:09 The orbitofrontal cortex’ role and the abstract to concrete pleasure gradient.

08:13 How to be happier by understanding the neuroscience of pleasure.

11:40 Summary.

-