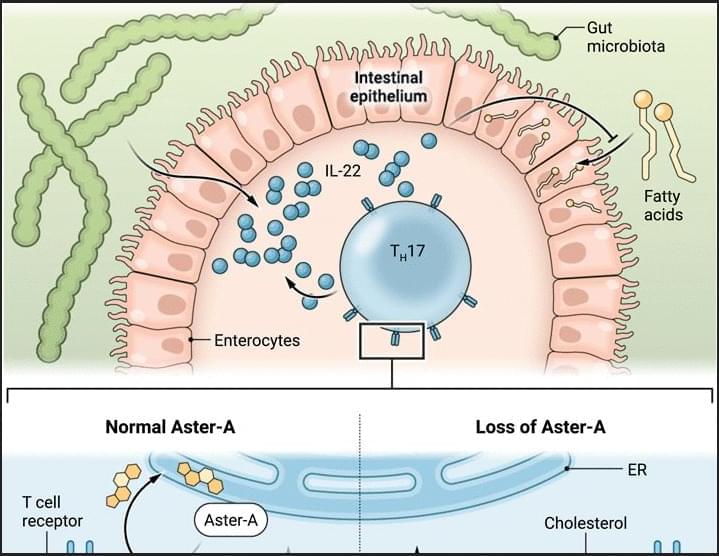

Microbes, immune cells, and enterocytes interact to regulate the intake of lipids in the mouse gut

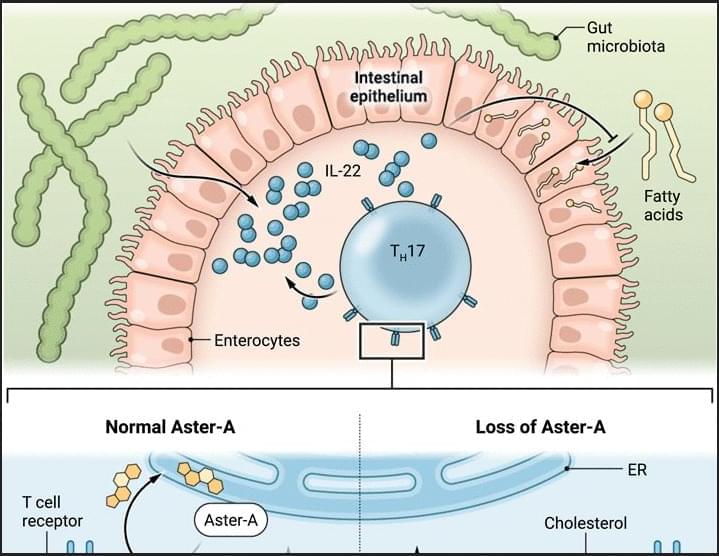

A new study has revealed how phosphorus, a nutrient essential for photosynthesis, surged into ancient oceans and started Earth’s first major rise in atmospheric oxygen more than 2 billion years ago.

Dr. Matthew Dodd, from UWA’s School of Earth and Oceans, is lead author of the study published in Nature Communications. “By fueling blooms of photosynthetic microbes, these phosphorus pulses boosted organic carbon burial and allowed oxygen to accumulate in the air, a turning point that ultimately made complex life possible,” Dr. Dodd said.

The research combined a global archive of ancient carbonate rocks with modeling to simulate Earth’s climate system and show that ocean phosphorus and atmospheric oxygen rose and fell together during the Great Oxidation Event.

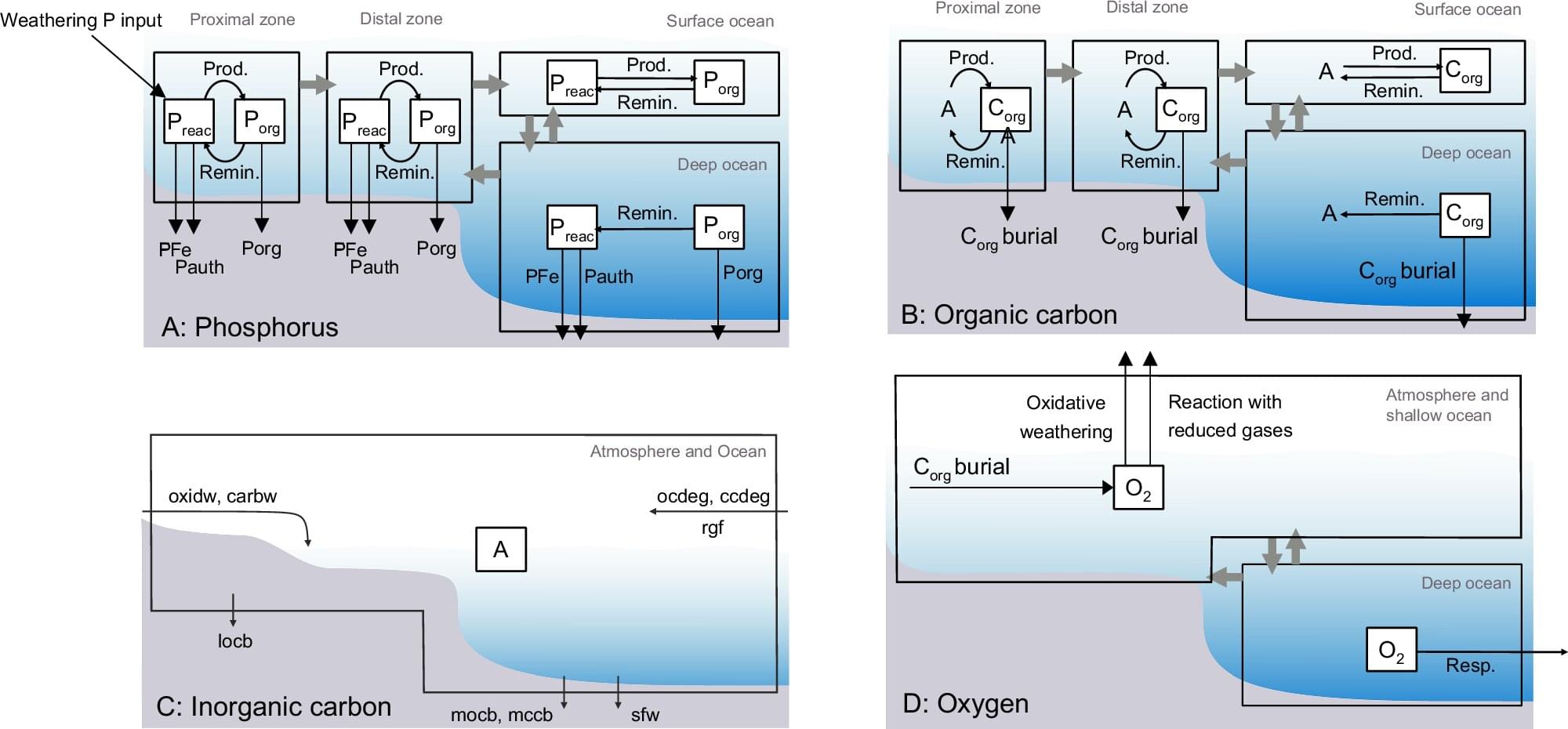

Photo-induced force microscopy began as a concept in the mind of Kumar Wickramasinghe when he was employed by IBM in the early years of the new millennium. After he came to the University of California, Irvine in 2006, the concept evolved into an invention that would revolutionize research by enabling scientists to study the fundamental characteristics of matter at nanoscale resolution.

Since the earliest experimental uses of PiFM around 2010, the device, which reveals the chemical composition and spatial organization of materials at the molecular level, has become a tool of choice for researchers in fields as diverse as biology, geology, materials science and even advanced electronics manufacturing.

“This is the story of a technology that was inspired by work at IBM, was invented and developed at UC Irvine, then got spun off, and now we have instruments on all continents across the world except for Antarctica,” says Wickramasinghe, Henry Samueli Endowed Chair and Distinguished Professor emeritus of electrical engineering and computer science who now holds the title of UC Irvine Distinguished Research Professor. “Almost anywhere serious research is happening, there are people out there who are using PiFM to discover new things.”

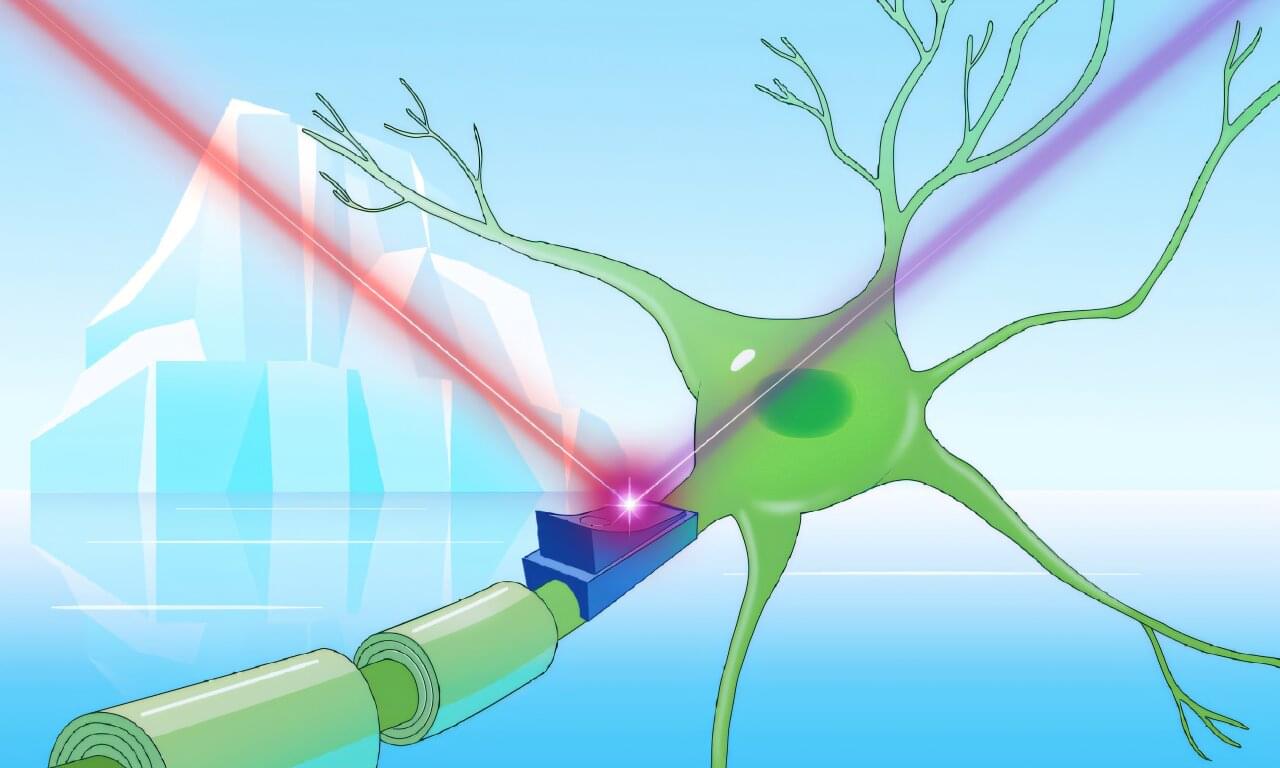

Imagine the magnificent glaciers of Greenland, the eternal snow of the Tibetan high mountains, and the permanently ice-cold groundwater in Finland. As cold and beautiful as these are, for the structural biologist Kirill Kovalev, they are more importantly home to unusual molecules that could control brain cells’ activity.

Kovalev, EIPOD Postdoctoral Fellow at EMBL Hamburg’s Schneider Group and EMBL-EBI’s Bateman Group, is a physicist passionate about solving biological problems. He is particularly hooked by rhodopsins, a group of colorful proteins that enable aquatic microorganisms to harness sunlight for energy.

“In my work, I search for unusual rhodopsins and try to understand what they do,” said Kovalev. “Such molecules could have undiscovered functions that we could benefit from.”

Because oxygen-bearing sulfate minerals trap and preserve signals from Earth’s atmosphere, scientists closely study how they form. Sulfates are stable over billions of years, so their oxygen isotopes are seen as a time capsule, reflecting atmospheric conditions while they were evolving on early Earth—and possibly on its planetary neighbor Mars.

A new study led by a University of Utah geochemist examines how sulfate forms when pyrite, commonly known as “fool’s gold,” is oxidized in environments teeming with microbes versus those without them. The researchers focused on Spain’s Rio Tinto, a contaminated river passing through a region where iron and copper were mined for thousands of years.

The paper titled, “Triple-oxygen isotopic evidence of prolonged direct bioleaching of pyrite with O2,” appears in Earth and Planetary Science Letters.

Modern chemistry is increasingly focused on developing sustainable processes that reduce energy consumption and minimize waste. Photocatalysis, which uses light to promote chemical reactions, offers a promising alternative to more aggressive conventional methods. However, most existing photocatalysts are homogeneous—they dissolve in the reaction medium and cannot be easily recovered or reused—and they typically rely on blue or ultraviolet light, which is more energy-demanding and penetrates poorly into reaction mixtures, limiting their large-scale and biological applications.

Researchers at the Center for Research in Biological Chemistry and Molecular Materials (CiQUS) have developed an innovative, more sustainable method that uses red light—a low-energy, deeply penetrating light source —together with recyclable solid catalysts to promote chemical reactions cleanly and efficiently. The study highlights the potential of covalent organic frameworks (COFs) as red-light-active heterogeneous photocatalysts, a field that remains largely unexplored. This combination of reusable materials and mild light represents a significant step toward greener chemical methodologies.

The work is published in the Journal of the American Chemical Society.

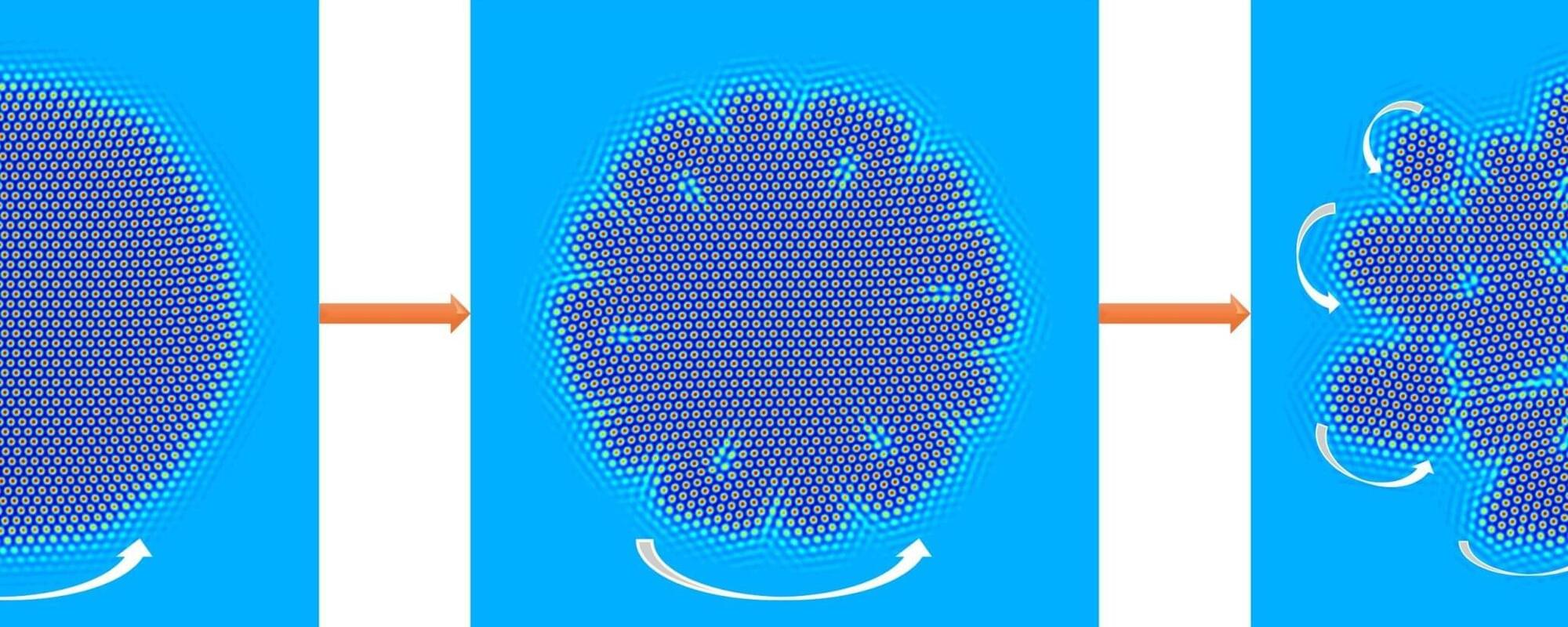

It sounds bizarre, but they exist: crystals made of rotating objects. Physicists from Aachen, Düsseldorf, Mainz and Wayne State (Detroit, U.S.) have jointly studied these exotic objects and their properties. They easily break into individual fragments, have odd grain boundaries and evidence defects that can be controlled in a targeted fashion.

In an article published in the Proceedings of the National Academy of Sciences, the researchers outline how several new properties of such transverse interaction systems can be predicted by applying a comprehensive theory.

Transverse forces can occur in synthetic systems, such as in certain magnetic solids. They exist in systems of living organisms too, however. In an experiment observing a host of starfish embryos conducted at American university MIT, it was found that, through their swimming movements, the embryos influence each other in a manner leading them to rotate around one another.

Networks are systems comprised of two or more connected devices, biological organisms or other components, which typically share information with each other. Understanding how information moves between these connected components, also known as nodes, could help to advance research focusing on numerous topics, ranging from artificial intelligence (AI) to neuroscience.

To measure the directional flow of information in systems, scientists typically rely on a mathematical construct known as transfer entropy, which essentially quantifies the rate at which information is transmitted from one node to another. Yet most strategies for calculating transfer entropy developed so far rely on approximations, which significantly limits their accuracy and reliability.

Researchers at AMOLF, a fundamental physics institute in the Netherlands, recently developed a computational algorithm that can precisely quantify transfer entropy in a wide range of complex networks. Their algorithm, introduced in a paper published in Physical Review Letters, opens new exciting possibilities for the study of information transfer in both biological and engineered networks.