Watch this studio 3D print a castle. 🤯 👍

Credit: Trideo.

Circa 2020

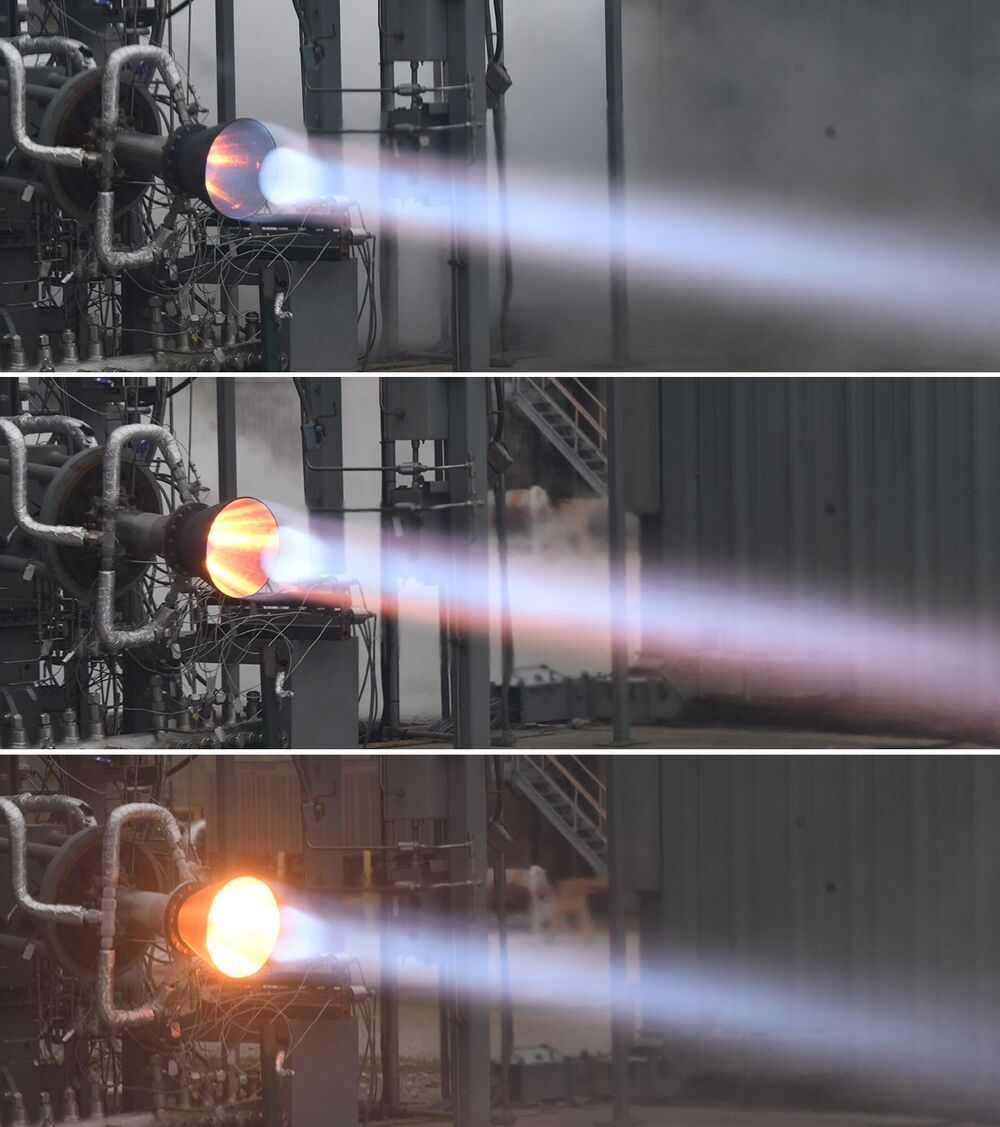

Learn how a young team of additive manufacturing engineers helped bring 3D printed parts to the design of the GE9X, the world’s largest jet engine.

Stefka Petkova enjoys building things. It’s a passion she’s had since she was a small child when her dad, an electrician who liked to work on cars, kept the door to his workshop open. “I was exposed to that as a very young child and just got a lot of encouragement,” says Petkova, who she spent many afternoons watching him weld and wire automobiles.

Her childhood tinkering led her to study mechanical engineering at the University of North Florida, near America’s Space Coast, where she joined the school’s space club. She traveled with the club to Cocoa Beach to watch the liftoff of Space Shuttle Atlantis in 2011, NASA’s final flight in its Space Shuttle Program. “At the Atlantis launch, we were able to go in the overhaul facility, touch the space tiles protecting the shuttles and talk to the engineers,” she says. “It was an amazing experience.”

3D-printed parts can make rocket engines lighter, less expensive and more efficient.

At Marshall, we’re working with our industry partners to test the latest advances in additive manufacturing technologies:

NASA is partnering with Aerojet Rocketdyne to advance 3D printing technologies, known as metal additive manufacturing, and its capabilities for liquid rocket engines in landers and on-orbit stages/spacecraft.

Why luxury brands like Hermès, Iris Van Herpen, and Stella McCartney are turning to mushrooms for an eco-alternative to leather.

The wondrous fungi-inspired creations in Dutch couture designer Iris Van Herpen’s Spring 2021 collection are like nothing else in the fashion world. Undulating crowns of brass coils top delicate micro-plissé gowns with bodices formed from sinuous silk tendrils. An early adopter of 3D printing and advocate for sustainability, van Herpen has emerged as a kind of oracle within the fashion industry. She spent lockdown in Amsterdam reading biologist Merlin Sheldrake’s book, Entangled Life: How Fungi Make Our Worlds, Change Our Minds & Shape Our Futures, which describes the hidden world of mycelium, the sprawling underground root-like networks of fungi (the visible part we know as mushrooms are akin to fruit on trees).

I still don’t get how there seems to be No organized effort anywhere to achieve the ability to 3D print a perfect genetic match of all organs by 2025 — 2030. You would think some government somewhere would want to work round the clock on this.

NIBIB-funded engineers at the University of Buffalo have fine-tuned the use of stereolithography for 3D printing of organ models that contain live cells. The new technique is capable of printing the models 10–50 times faster than the industry standard-;in minutes instead of hours-; a major step in the quest to create 3D-printed replacement organs.

Conventional 3D printing involves the meticulous addition of material to the 3D model with a small needle that produces fine detail but is extremely slow —taking six or seven hours to print a model of a human part, such as a hand, for instance. The lengthy process causes cellular stress and injury inhibiting the ability to seed the tissues with live, functioning cells.

The method developed by the SUNY Buffalo group, led by Rougang Zhao, PhD, Associate Professor of Biomedical Engineering in the Jacobs School of Medicine & Biomedical Sciences, takes a different approach that minimizes damage to live cells. The rapid, cell friendly technique is a significant step towards creating printed tissues infused with large numbers of living cells.

Tomographic 3D printing is a revolutionary technology that uses light to create three-dimensional objects. A projector beams light at a rotating vial containing photocurable resin, and within seconds the desired shape forms inside the vial. The light projections needed to solidify specific 3D regions of the polymer are calculated using tomographic imaging concepts.

The technology was first demonstrated by researchers at the University of California, Berkeley and Lawrence Livermore National Labs in 2019, and a Swiss group at École Polytechnique Fédérale de Lausanne (EPFL) in 2020. It is significantly faster than traditional 3D printing in layers, can print around existing objects, and does not require support structures.

Though incredible, the technology can get messy in the lab. The vial’s round shape makes it refract rays like a lens. To counter this, experts use a rectangular index-matching bath that provides a flat surface for rays to pass through correctly. The vial of resin must be dipped in and out of the bath for each use—creating a slimy situation.

Desktop Metal today announced the launch of wood 3D printing tool, Forust. Founded in 2019, the company specializes in 3D printing for interior design. The company’s “non-destructive” printing methods have managed to largely fly under the radar, with minimal press coverage until now — making them a pretty ideal acquisition candidate.

In fact, the gross assets acquisition actually occurred back in October 2020, according to a filing, which pegs it at a price at $2.5 million, including $2 million in cash considerations. Since then, it seems, the two have been working together ahead of an official launch.

In a press release issued today, Desktop Metal is positioning Forust as the name of the new manufacturing process now in the company’s portfolio. The technology utilizes cellulose dust and lignin, byproducts from the wood and paper industries, respectively.