This may be good news for those who have damaged joints due to sports or old age.

😃

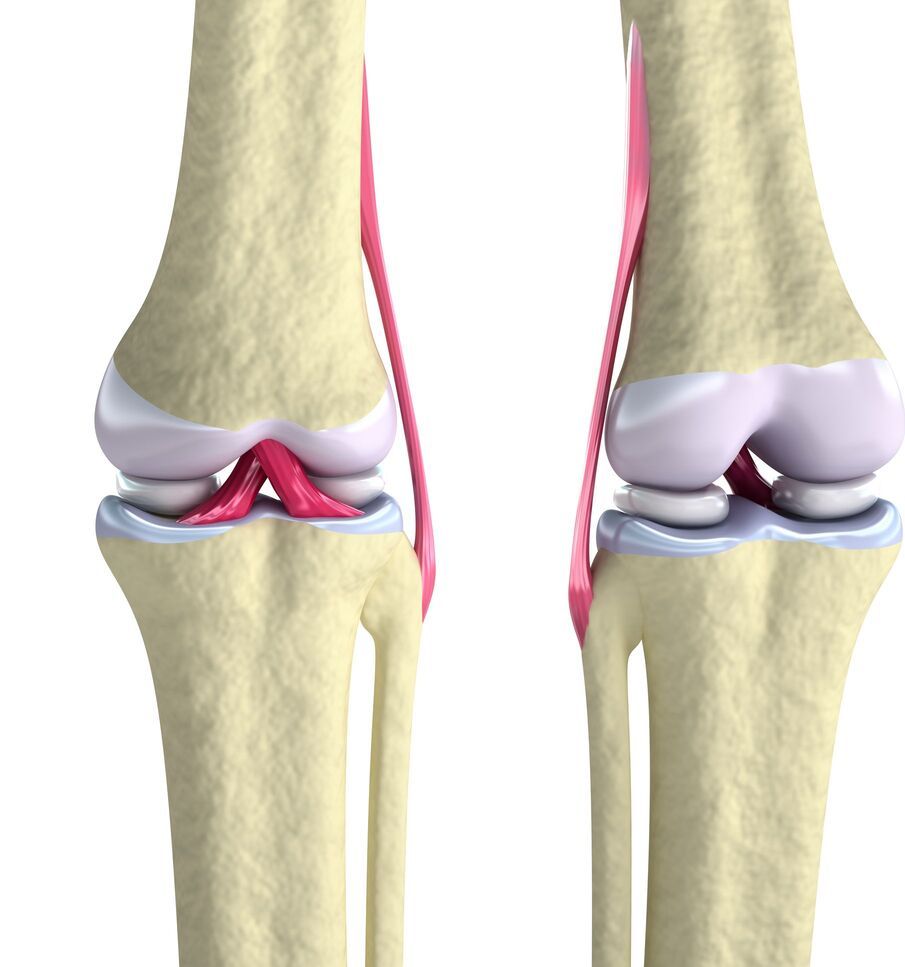

Human knees are notoriously vulnerable to injury or wearing out with age, often culminating in the need for surgery. Now researchers have created new hybrid bioinks that can be used to 3D print structures to replace damaged cartilage in the knee.

The meniscus is the rubbery cartilage that forms a C-shaped cushion in your knee, preventing the bones of your upper and lower leg from rubbing against each other. This stuff is susceptible to damage from sports injuries, but can also wear out with age – and if it gets particularly bad, sometimes the only thing left to do is surgically remove some of the damaged meniscus.

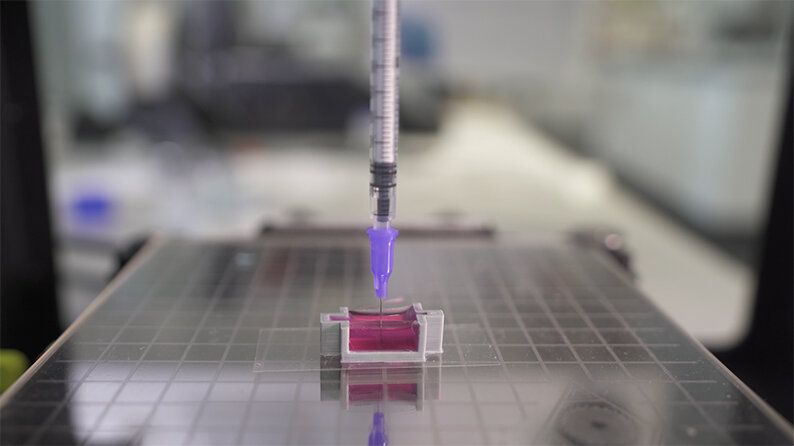

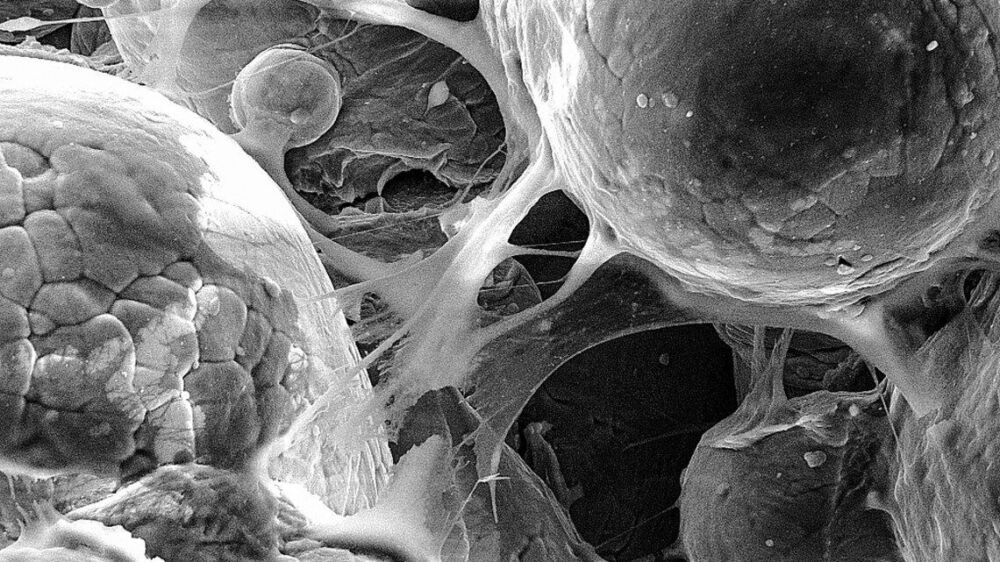

For the new proof-of-concept study, researchers at the Wake Forest Institute for Regenerative Medicine (WFIRM) demonstrated a new method for 3D bioprinting that creates both the cartilage and the supporting structures. The team used the Integrated Tissue and Organ Printing System (ITOPS), which has been used in past studies to print complex tissues such as bones, muscles and even ears.