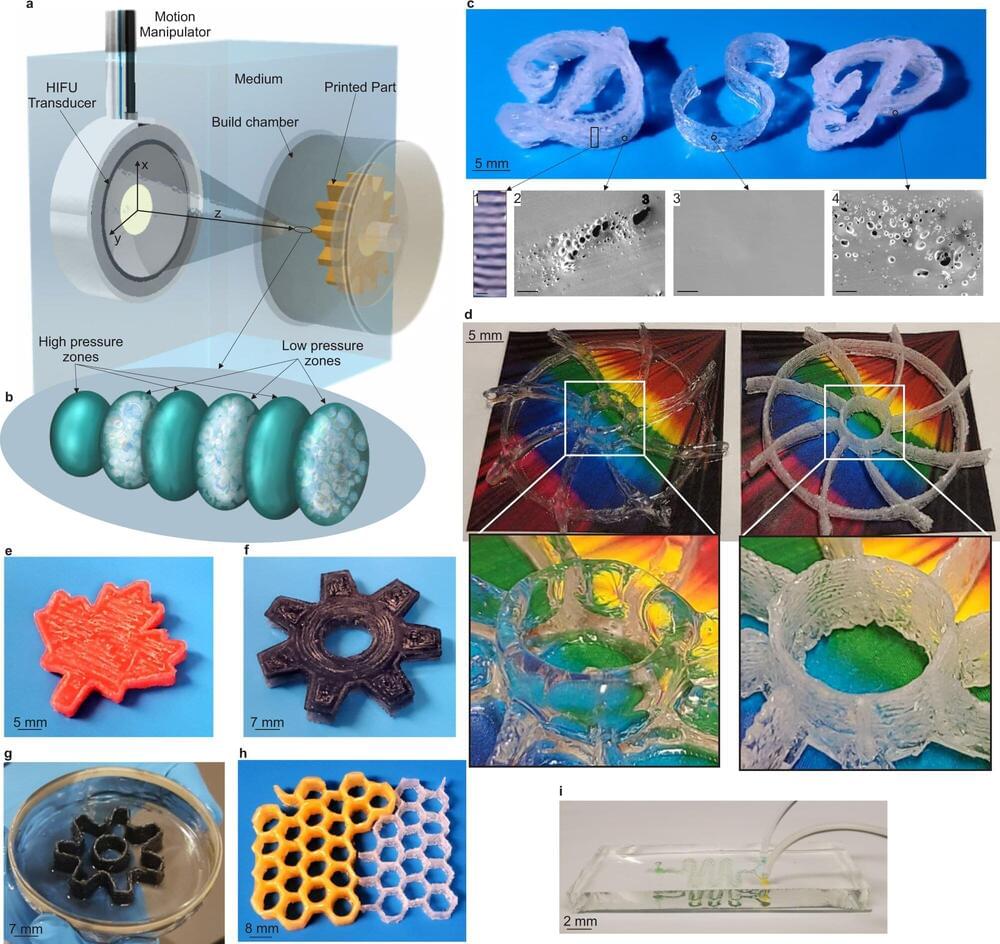

Most 3D printing methods currently in use rely either on photo (light)- or thermo (heat)-activated reactions to achieve precise manipulation of polymers. The development of a new platform technology called direct sound printing (DSP), which uses soundwaves to produce new objects, may offer a third option.

The process is described in a paper published in Nature Communications. It shows how focused ultrasound waves can be used to create sonochemical reactions in minuscule cavitation regions—essentially tiny bubbles. Extremes of temperature and pressure lasting trillionths of a second can generate pre-designed complex geometries that cannot be made with existing techniques.

“Ultrasonic frequencies are already being used in destructive procedures like laser ablation of tissues and tumors. We wanted to use them to create something,” says Muthukumaran Packirisamy, a professor and Concordia Research Chair in the Department of Mechanical, Industrial and Aerospace Engineering at the Gina Cody School of Engineering and Computer Science. He is the paper’s corresponding author.