Likened by its creators to an “ornate layered cake,” the Tor Alva has been completed in Switzerland. Hailed as the world’s tallest 3D-printed building, this remarkable structure rises to an impressive height of 30 m (98.5 ft).

Tor Alva (aka White Tower) is located in the small alpine village of Mulegns that’s currently home to just 11 people. It was created by researchers at ETH Zurich, in collaboration with cultural foundation Fundaziun Origen, to show off the capabilities of cutting-edge 3D-printing techniques.

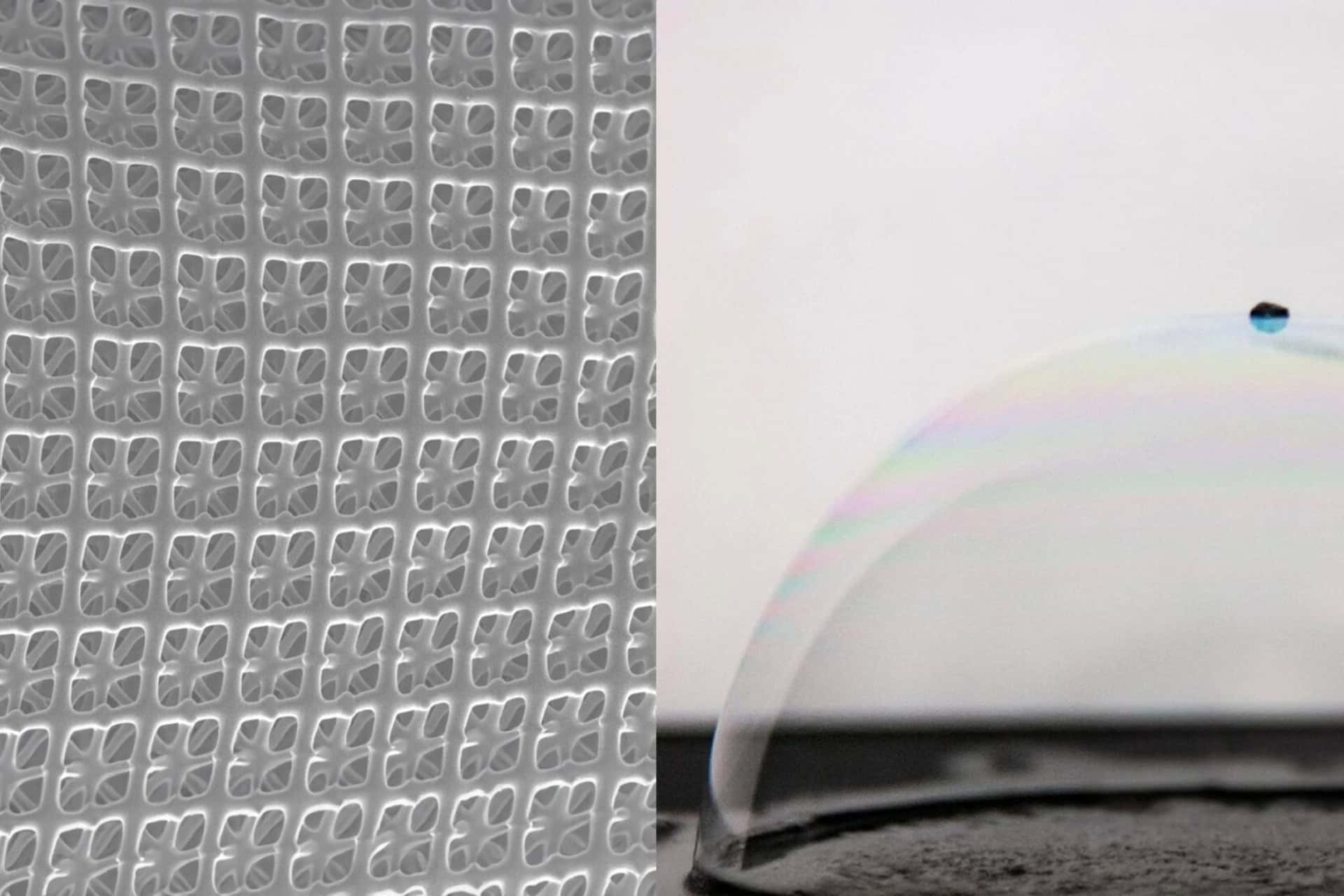

Architect Michael Hansmeyer and ETH Professor of Digital Building Technologies Benjamin Dillenburger designed its actual form, which consists of an intricate structure of 32 white concrete columns that rise over four floors and taper before fanning out to top out with a dome. The interior, meanwhile, has a capacity for 32 visitors and includes stairs on each floor, with a performance space at the top.