A team of Penn State researchers has used a new 3D-printing method to produce a complex metal build that was once only possible with welding: fusing two metals together into a single structure.

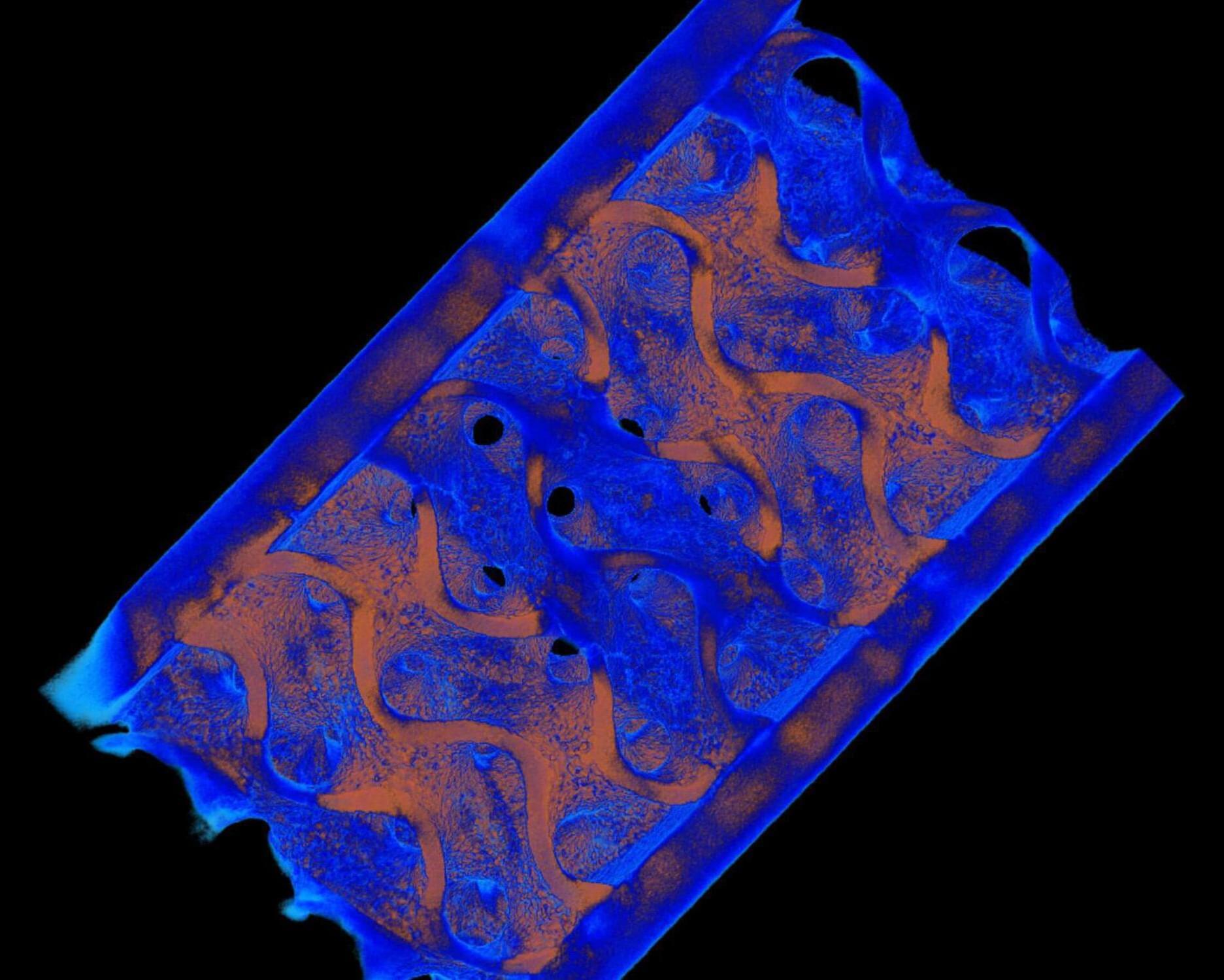

Using an advanced additive manufacturing process known as multi-material laser powder bed fusion—enabled by a newly acquired system in Penn State’s Center for Innovative Materials Processing Through Direct Digital Deposition (CIMP-3D)—the researchers printed a complex structure out of a blend of low-carbon stainless steel and bronze, which consists of 90% copper and 10% tin.

The researchers have published their approach in npj Advanced Manufacturing.