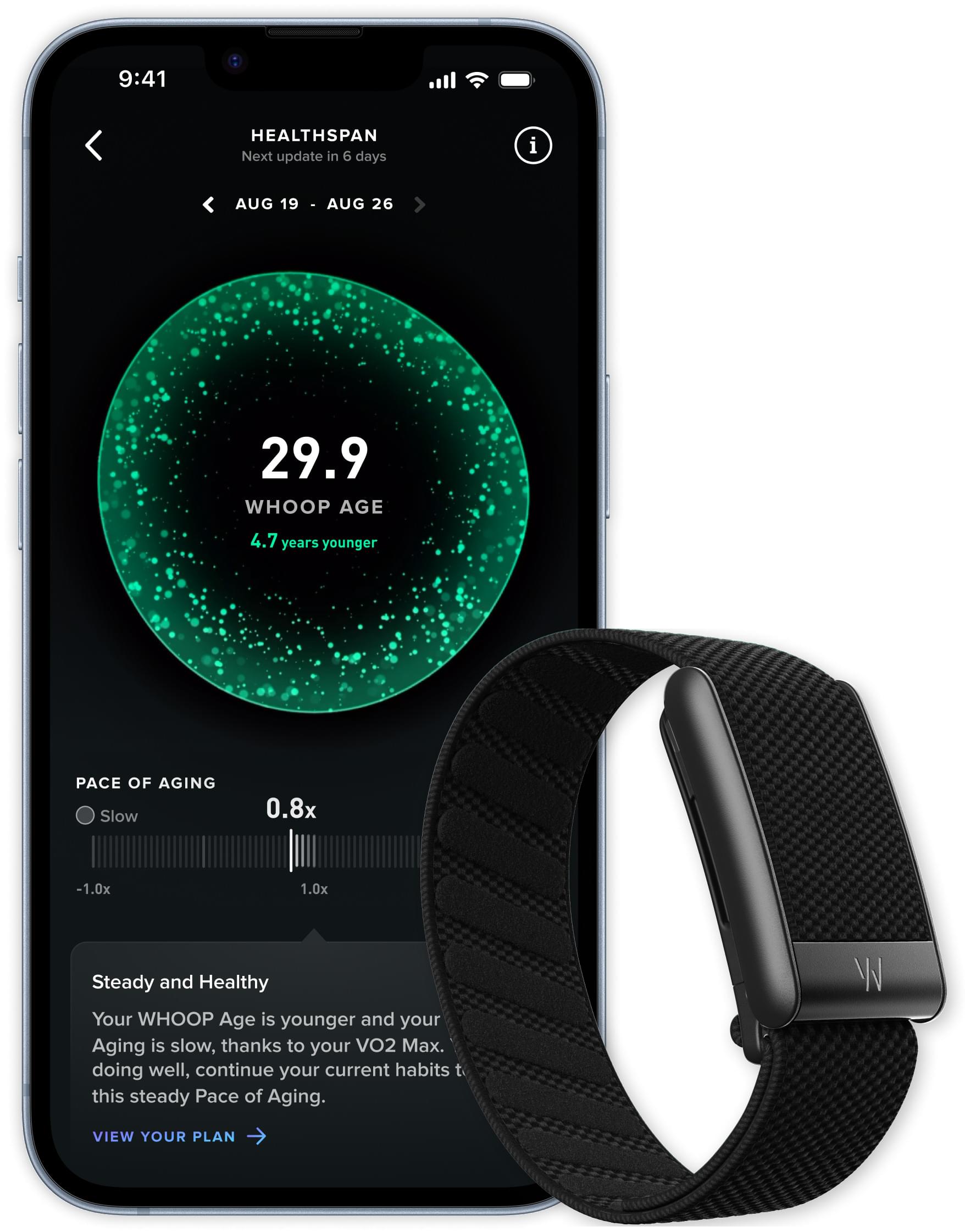

In the tech industry’s first telling, the post-smartphone world is a simple question of what and when: glasses? Watches? Pins? Armbands? Implants? It’s portrayed as a simple matter of progress — in consumer technology, things must be replaced by newer and better things — but also as a reaction to the burdens and distractions of the previous great gadget, from which new gadgets will set us free.

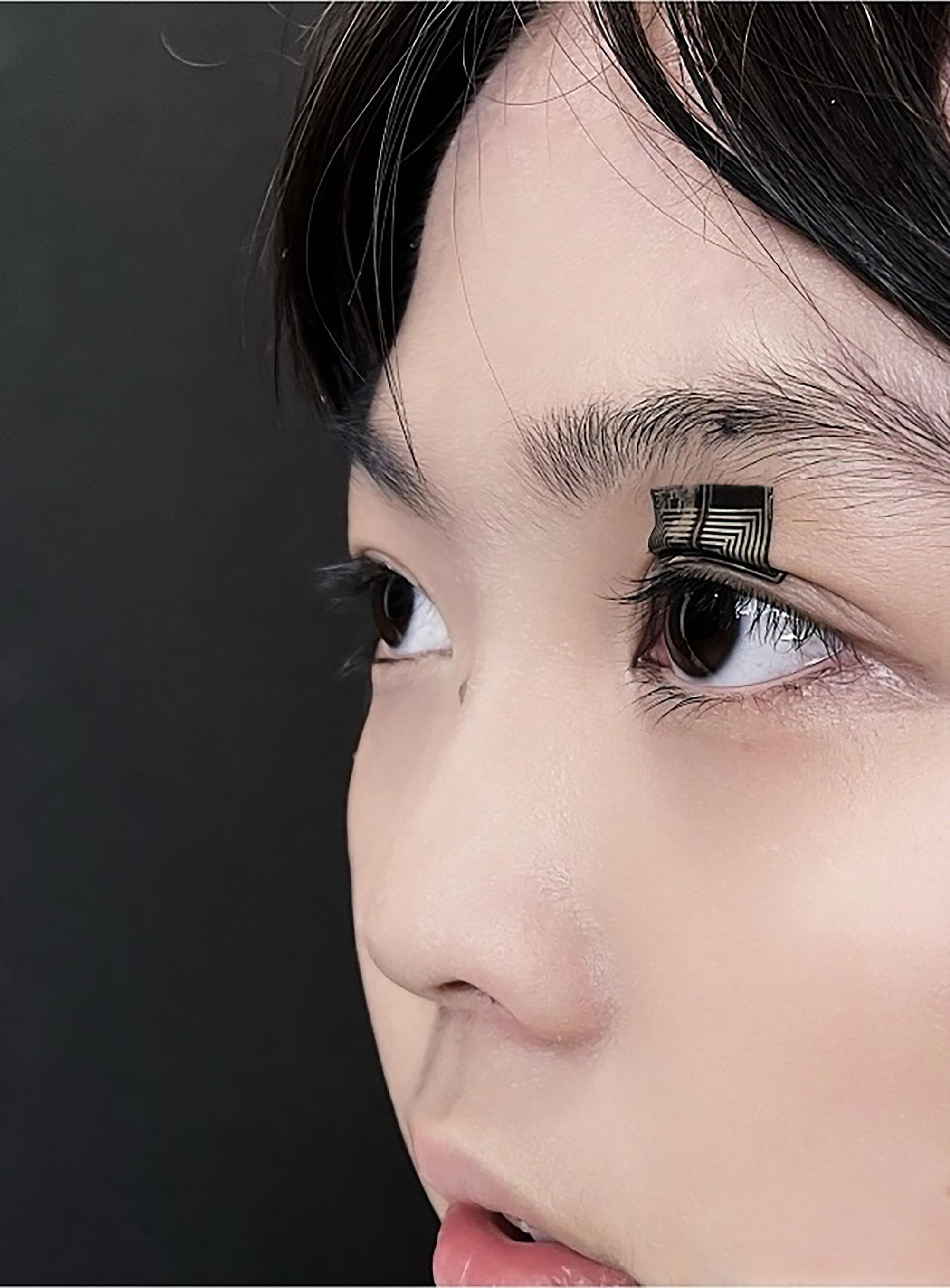

A survey of the post-phone landscape as it exists, though, reveals a complication in this consumerist liberation story. Someday, a new gadget may usher us into the post-smartphone world; in the meantime, the industry will have us trying everything else at once: on our faces, in our ears, around our necks, and on our appendages. Our phones — and the always-on, data-and-attention-hungry logic they represent — aren’t being replaced. They’re being extended.