Most people are well aware of the effects of chronic stress in the modern world. While some stress can be a good thing, like the type of stress your body feels during an intense workout, prolonged or chronic stress can lead to a myriad of health problems, including anxiety, heart disease, and inflammation. And, at a larger scale, the high prevalence of chronic stress in the population increases the burden on public health systems.

Tracking stress responses could help people better understand and manage stress, but stress can be difficult to measure and monitor in an objective and precise manner. Stress hormones fluctuate throughout the day, but current stress assessment methods rely on subjective self-reports, heart rate, or wearable sensors that only measure cortisol in a non-continuous manner. It is difficult to get a full picture of a person’s stress response and its long-term effects with these current methods.

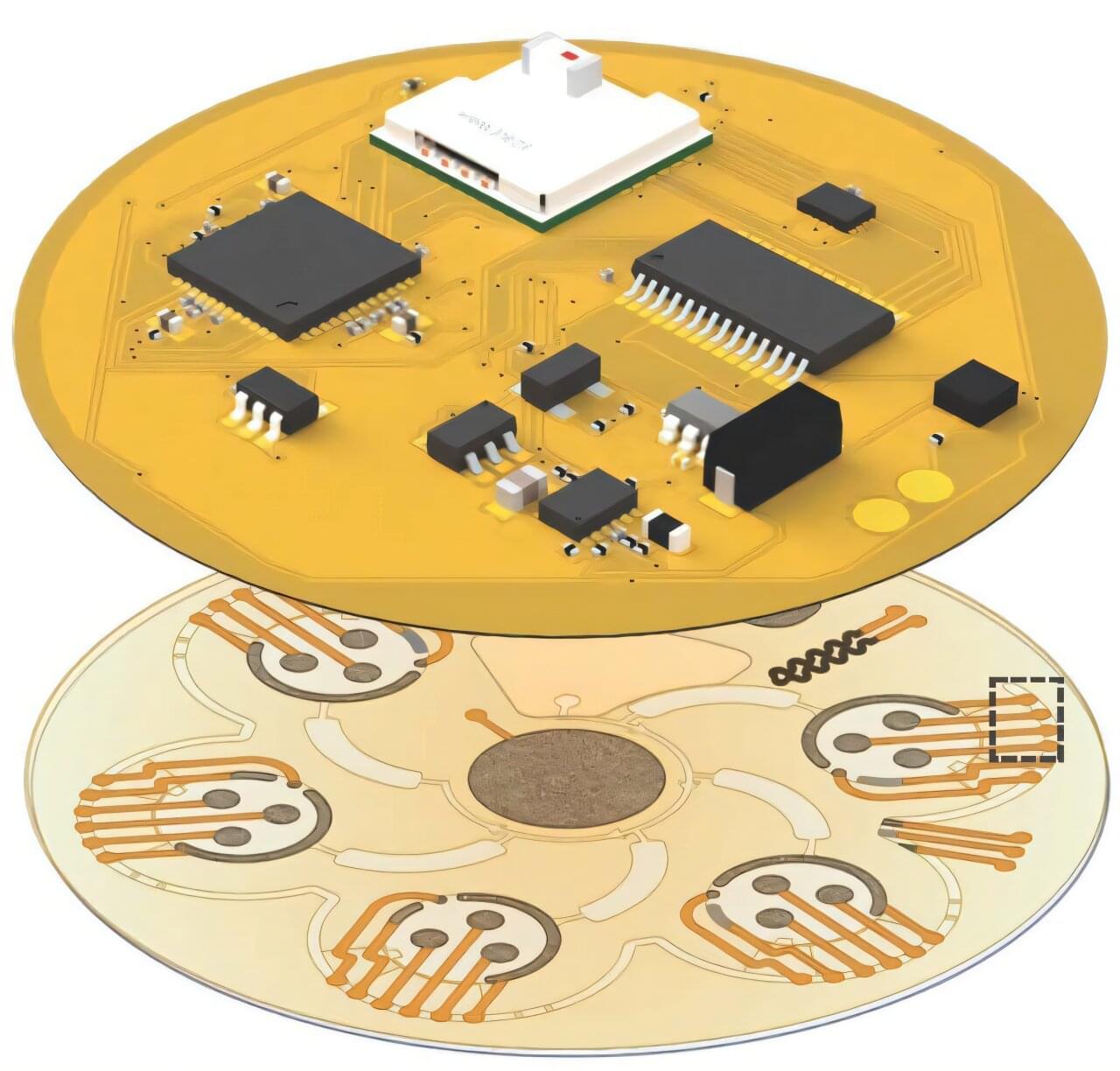

However, scientists have recently developed a device called the “Stressomic,” a wearable biosensor that can continuously monitor cortisol, epinephrine, and norepinephrine in sweat—which might just pave the way for better stress management. The device was recently tested in a study published in Science Advances. They claim that it’s capable of distinguishing between acute and chronic stress and can be worn as a simple biocompatible patch placed on the skin.