Year 2019 😁

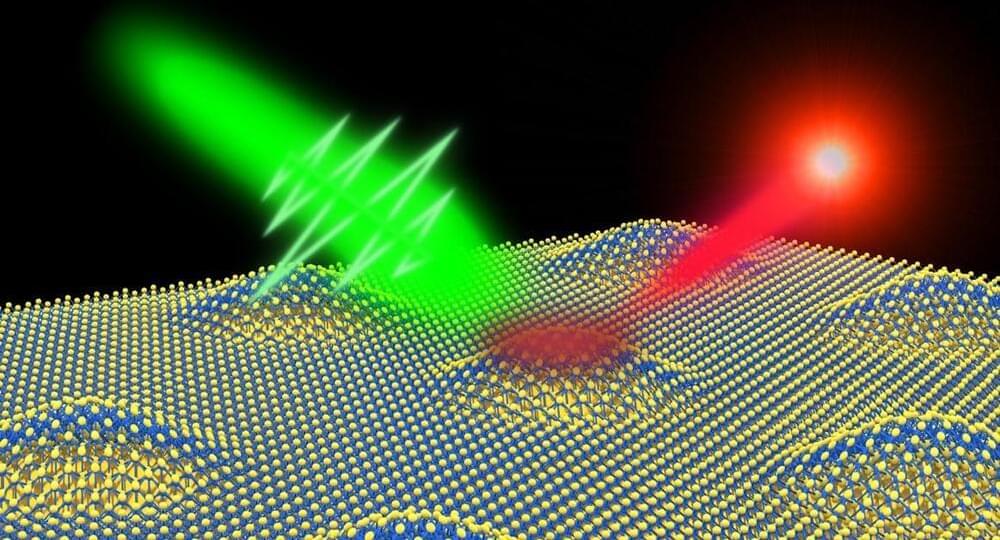

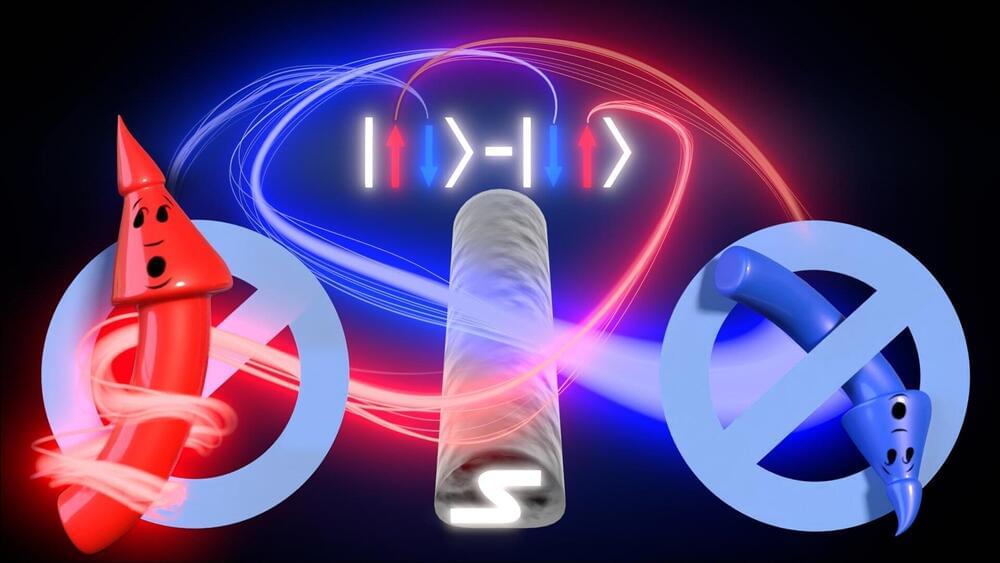

Semiconducting carbon nanotubes (CNTs) printed into thin films offer high electrical performance, significant mechanical stability, and compatibility with low-temperature processing. Yet, the implementation of low-temperature printed devices, such as CNT thin-film transistors (CNT-TFTs), has been hindered by relatively high process temperature requirements imposed by other device layers—dielectrics and contacts. In this work, we overcome temperature constraints and demonstrate 1D–2D thin-film transistors (1D–2D TFTs) in a low-temperature (maximum exposure ≤80 °C) full print-in-place process (i.e., no substrate removal from printer throughout the entire process) using an aerosol jet printer. Semiconducting 1D CNT channels are used with a 2D hexagonal boron nitride (h-BN) gate dielectric and traces of silver nanowires as the conductive electrodes, all deposited using the same printer.