Circa 2013 face_with_colon_three

“IMAGINE printing out a paper computer and tearing off a corner so someone else can use part of it.” So says Steve Hodges of Microsoft Research in Cambridge, UK. The idea sounds fantastical, but it could become an everyday event thanks in part to a technique he helped develop.

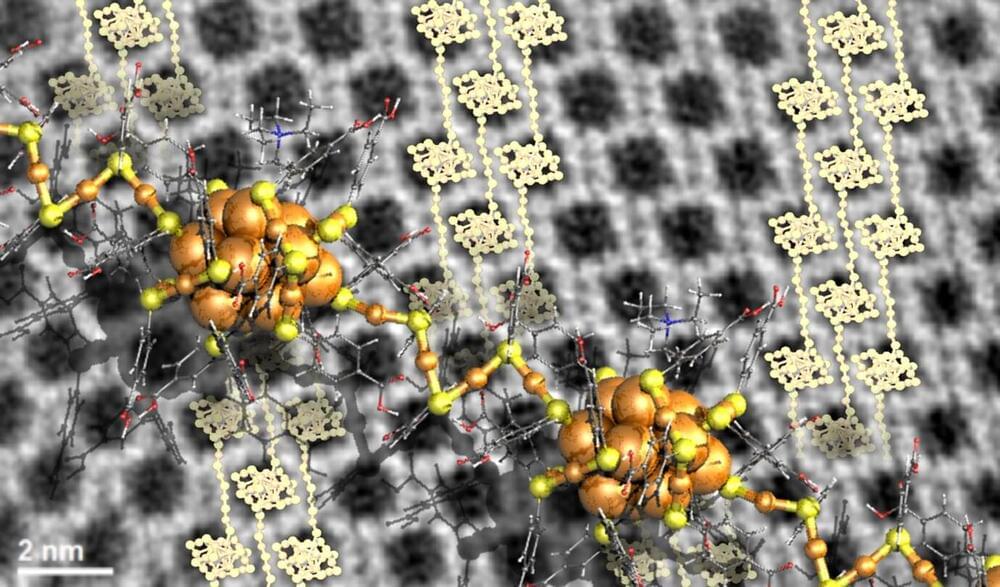

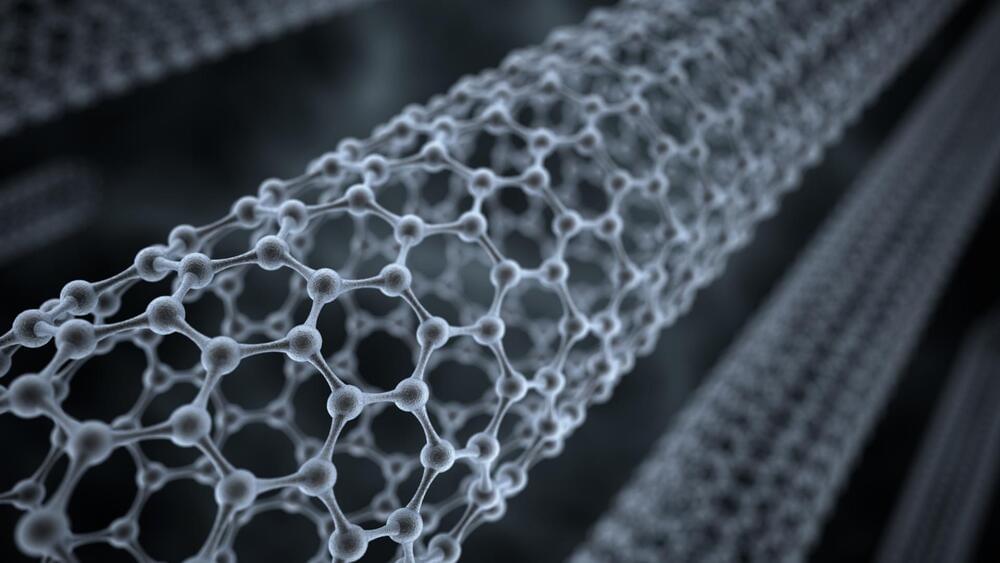

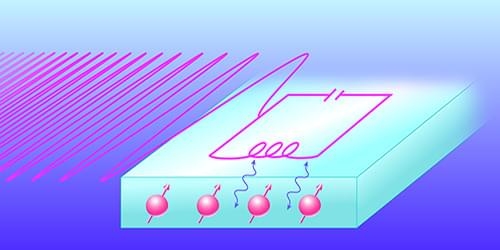

Hodges, along with Yoshihiro Kawahara and his team at the University of Tokyo, Japan, have found a way to print the fine, silvery lines of electronic circuit boards onto paper. What’s more, they can do it using ordinary inkjet printers, loaded with ink containing silver nanoparticles. Last month Kawahara demonstrated a paper-based moisture sensor at the Ubicomp conference in Zurich, Switzerland.

Kawahara says the idea is perfect for the growing maker movement of inventors and tinkerers. Hobbyists will be able to test circuit designs by simply printing them out and throwing away anything that doesn’t work. That will reduce much of electronics to a craft akin to “sewing or origami”, he says.