In a recent leap forward for quantum computing and optical technologies, researchers have uncovered an important aspect of photon detection. Superconducting nanowire single-photon detectors (SNSPDs), pivotal in quantum communication and advanced optical systems, have long been hindered by a phenomenon known as intrinsic dark counts (iDCs). These spurious signals, occurring without any real photon trigger, significantly impact the accuracy and reliability of these detectors.

Understanding and mitigating iDCs are crucial for enhancing the performance of SNSPDs, which are integral to a wide range of applications, from secure communication to sensitive astronomical observations.

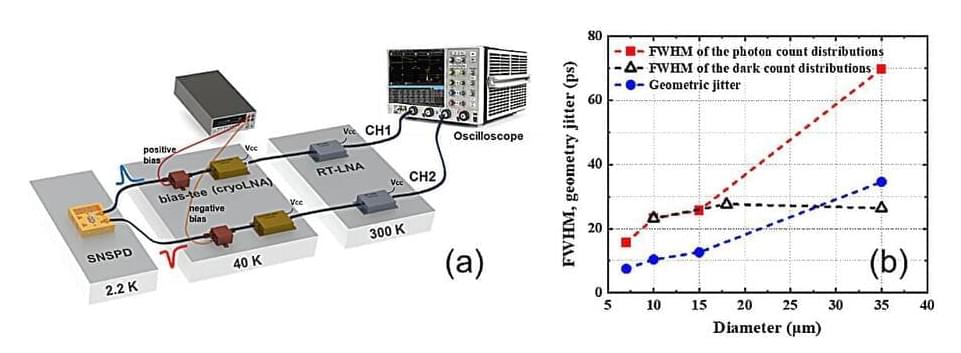

A team headed by Prof. Lixing You and Prof. Hao Li from Shanghai Institute of Microsystem and Information Technology (SIMIT), Chinese Academy of Sciences (CAS) employed a novel differential readout method to investigate the spatial distribution of iDCs in SNSPDs with and without artificial geometric constrictions. This approach allowed for a precise characterization of the spatial origins of iDCs, revealing the significant influence of minute geometric constrictions within the detectors.