Ohh nice! New vaccine science it seems though I’m not familiar with vaccines, this does seem like a novel approach. It’s kinda future proof to train the immune system to target proteins that are shared across all coronavirus’ I’m hoping it provides, as do they, that it provides a better solution than current vaccines.

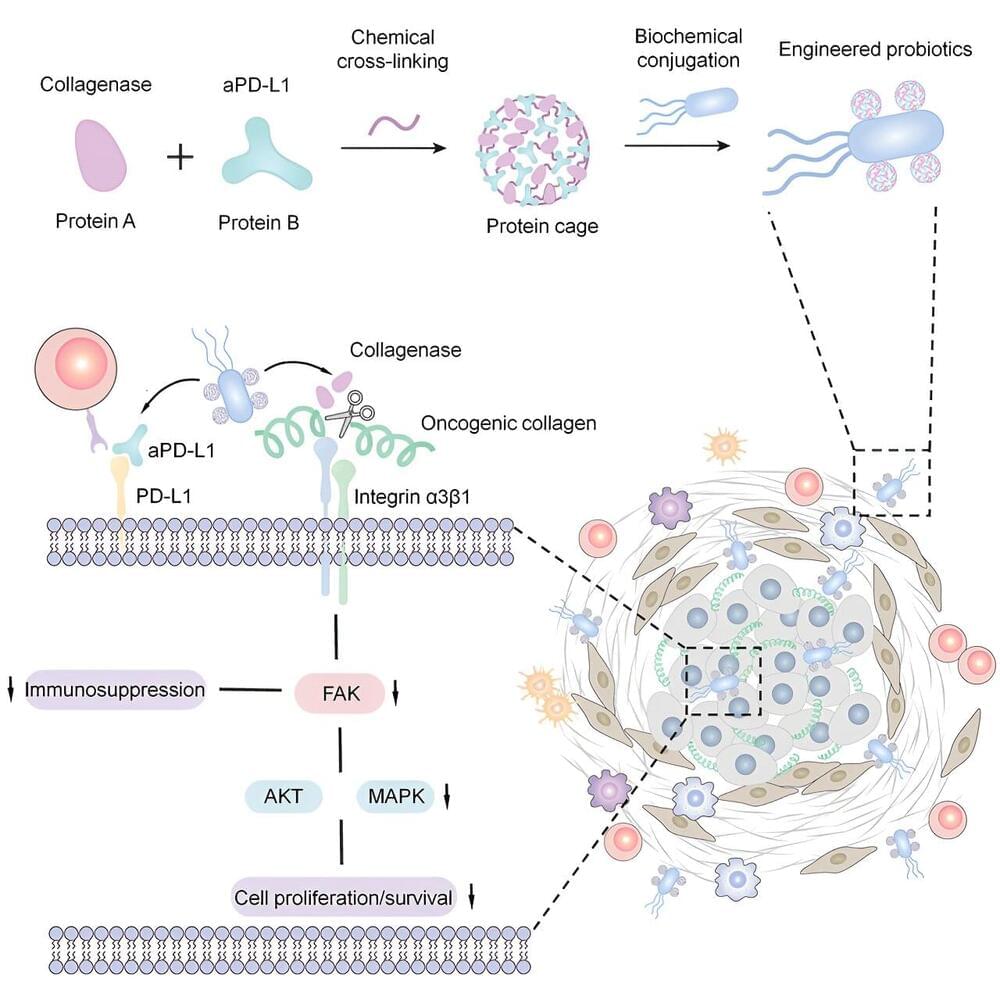

The vaccine is made by attaching harmless proteins from different coronaviruses to minuscule nanoparticles that are then injected to prime the body’s defences to fight the viruses should they ever invade.

Because the vaccine trains the immune system to target proteins that are shared across many different types of coronavirus, the protection it induces is extremely broad, making it effective against known and unknown viruses in the same family.

“We’ve shown that a relatively simple vaccine can still provide a scattershot response across a range of different viruses,” said Rory Hills, a graduate researcher at the University of Cambridge and first author of the report. “It takes us one step forward towards our goal of creating vaccines before a pandemic has even started.”