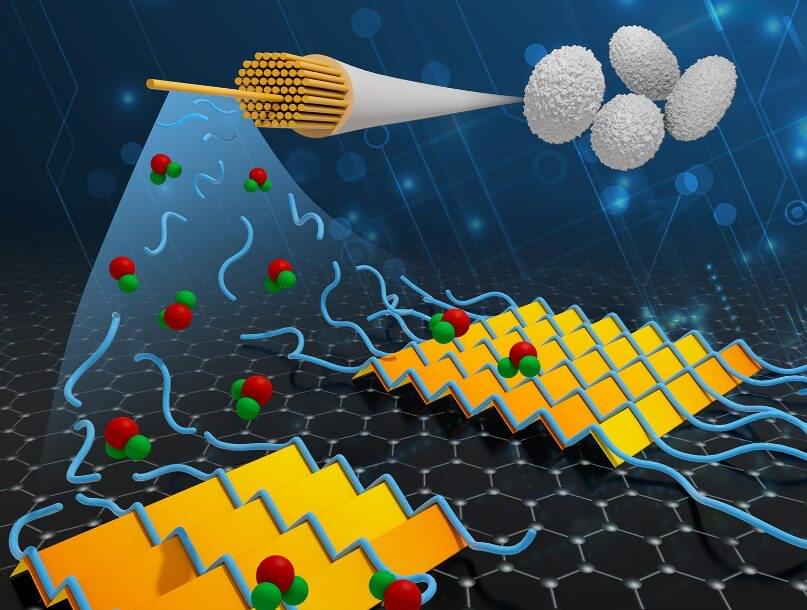

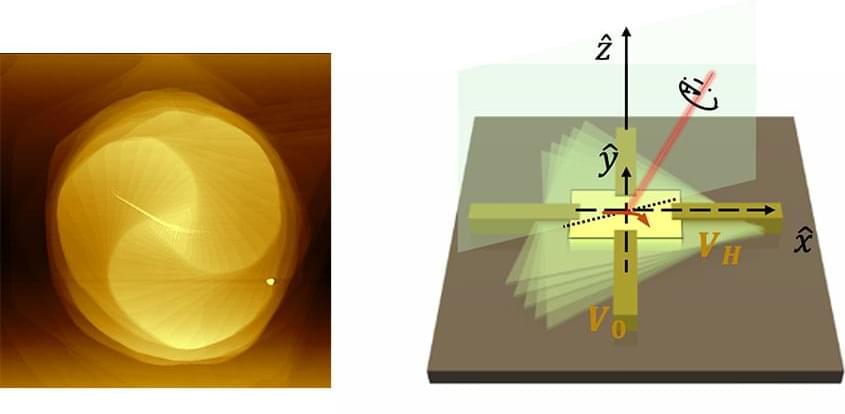

The team of chemists and composite materials researchers discovered a broadly applicable method of bonding plastics and synthetic fibers at the molecular level in a procedure called cross-linking. The cross-linking takes effect when the adhesive is exposed to heat or long-wave UV light making strong connections that are both impact-resistant and corrosion-resistant. Even with a minimal amount of cross-linking, the materials are tightly bonded.

“It turns out the adhesive is particularly effective in high-density polyethylene, which is an important plastic used in bottles, piping, geomembranes, plastic lumber, and many other applications,” says Professor Abbas Milani, director of UBC’s Materials and Manufacturing Research Institute, and the lead researcher at the Okanagan node of the Composite Research Network. “In fact, commercially available glues didn’t work at all on these materials, making our discovery an impressive foundation for a wide range of important uses.”

UVic Organic Chemistry Professor Jeremy Wulff, whose team led the design of the new class of cross-linking materials, collaborated with the UBC Survive and Thrive Applied Research to explore how it performed in real-world applications.