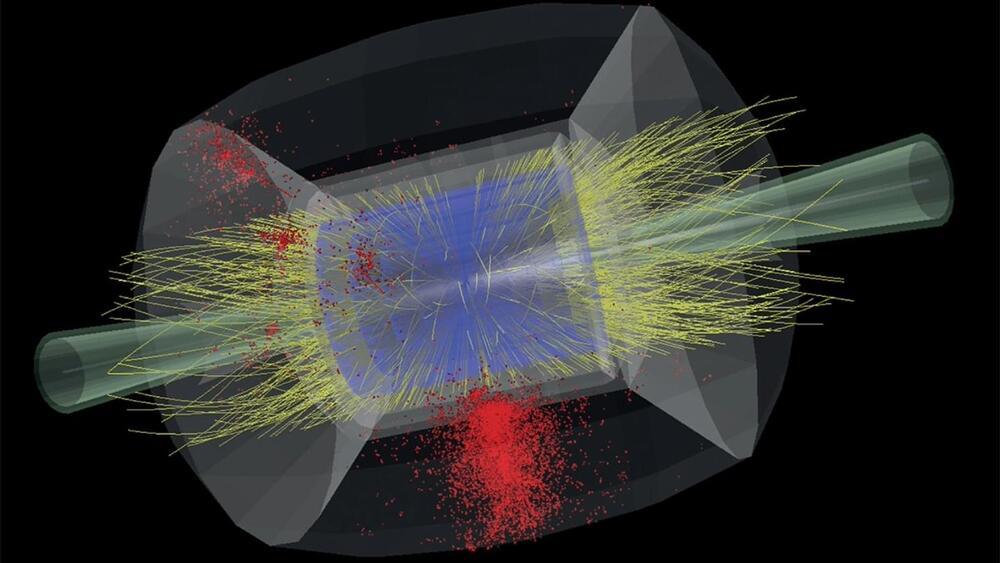

Now, scientists have not only cooled muons but also accelerated them in an experiment at the Japan Proton Accelerator Research Complex, or J-PARC, in Tokai. The muons reached a speed of about 4 percent the speed of light, or roughly 12,000 kilometers per second, researchers report October 15 at arXiv.org.

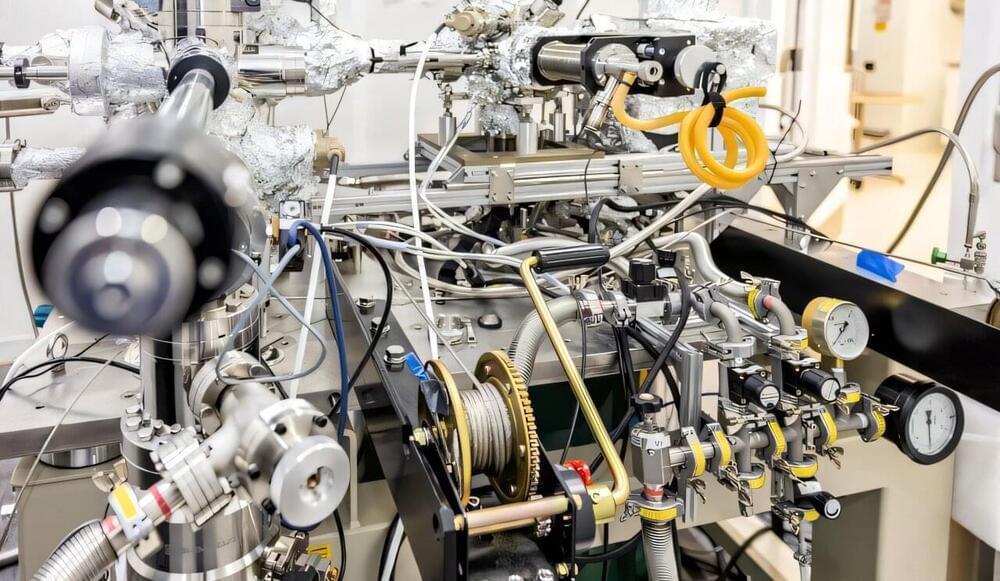

The scientists first sent the muons into an aerogel, a lightweight material that slowed the muons and created muonium, an atomlike combination of a positively charged muon and a negatively charged electron. Next, a laser stripped away the electrons, leaving behind cooled muons that electromagnetic fields then accelerated.

Muon colliders could generate higher energy collisions than machines that smash protons, which are themselves made up of smaller particles called quarks. Each proton’s energy is divvied up among its quarks, meaning only part of the energy goes into the collision. Muons have no smaller bits inside. And they’re preferable to electrons, which lose energy as they circle an accelerator. Muons aren’t as affected by that issue thanks to their larger mass.