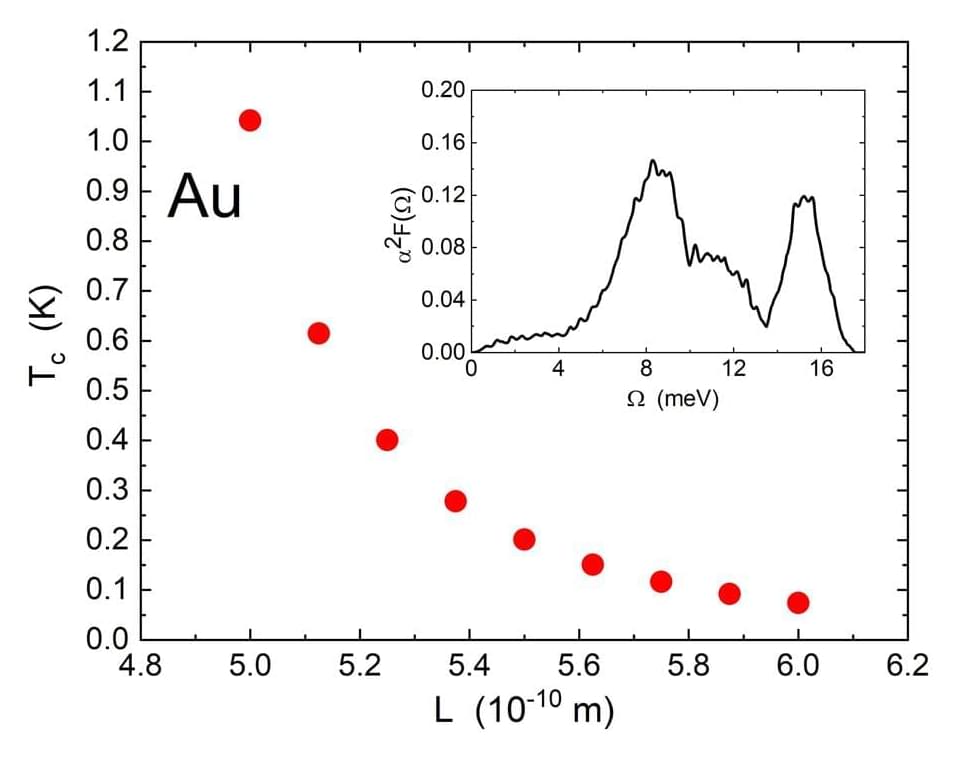

New materials designed by a University of Illinois Chicago graduate student may help scientists meet one of today’s biggest challenges: building superconductors that operate at normal temperatures and pressures.

A new hydrogel semiconductor from the University of Chicago offers a groundbreaking solution for bioelectronics, blending tissue-like properties with high electronic functionality, enhancing medical device integration and effectiveness.

The perfect material for interfacing electronics with living tissue is soft, stretchable, and as water-loving as the tissue itself, making hydrogels an ideal choice. In contrast, semiconductors, the key materials for bioelectronics such as pacemakers, biosensors, and drug delivery devices, are rigid, brittle, and hydrophobic, making them impossible to dissolve in the way hydrogels have traditionally been built.

Breakthrough in Bioelectronics.

Using muon spin rotation at the Swiss Muon Source SmS, researchers at the Paul Scherrer Institute (PSI) have discovered that a quantum phenomenon known as time-reversal symmetry breaking occurs at the surface of the Kagome superconductor RbV3Sb5 at temperatures as high as 175 K. This sets a new record for the temperature at which time-reversal symmetry breaking is observed among Kagome systems.

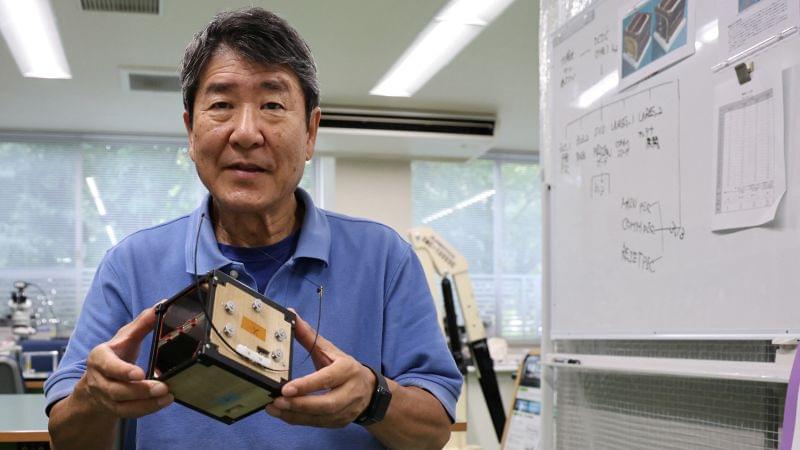

The world’s first wooden satellite, built by Japanese researchers, was launched into space on Tuesday, in an early test of using timber in lunar and Mars exploration.

LignoSat, developed by Kyoto University and homebuilder Sumitomo Forestry, will be flown to the International Space Station on a SpaceX mission, and later released into orbit about 400 kilometers (250 miles) above the Earth.

Named after the Latin word for “wood,” the palm-sized LignoSat is tasked to demonstrate the cosmic potential of the renewable material as humans explore living in space.

Old article. Simple and cheap solution.

MIT researchers have come up with a promising approach to controlling methane emissions and removing it from the air, using an inexpensive and abundant clay called zeolite.

The future of wireless technology—from charging devices to boosting communication signals—relies on the antennas that transmit electromagnetic waves becoming increasingly versatile, durable and easy to manufacture. Researchers at Drexel University and the University of British Columbia believe kirigami, the ancient Japanese art of cutting and folding paper to create intricate three-dimensional designs, could provide a model for manufacturing the next generation of antennas.

Recently published in the journal Nature Communications, research from the Drexel-UBC team showed how kirigami—a variation of origami—can transform a single sheet of acetate coated with conductive MXene ink into a flexible 3D microwave antenna whose transmission frequency can be adjusted simply by pulling or squeezing to slightly shift its shape.

The proof of concept is significant, according to the researchers, because it represents a new way to quickly and cost-effectively manufacture an antenna by simply coating aqueous MXene ink onto a clear elastic polymer substrate material.

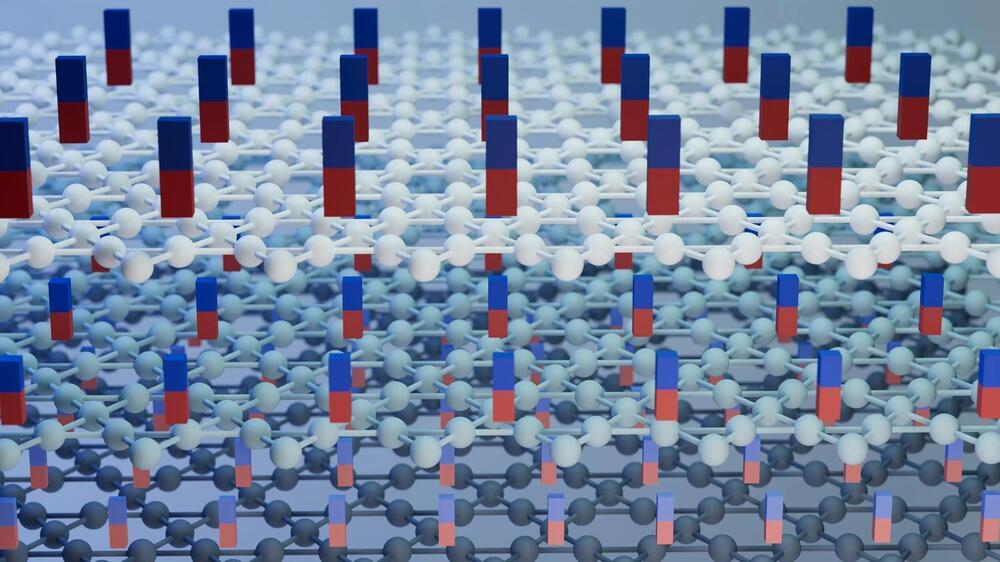

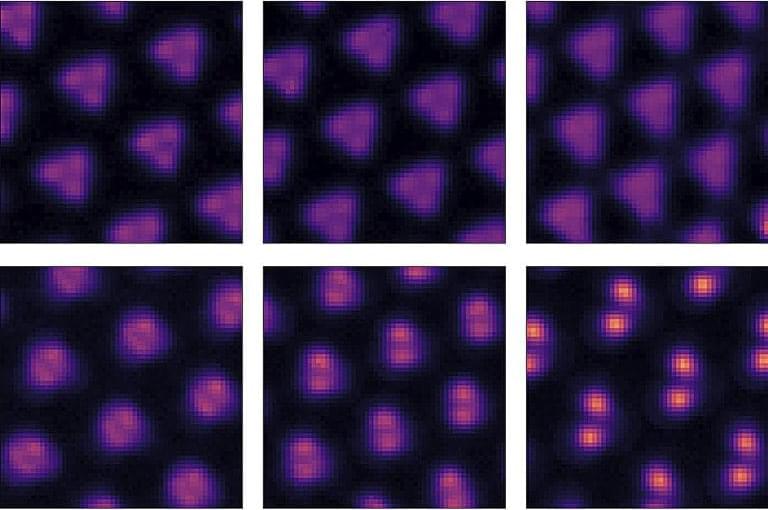

Moiré materials, such as twisted bilayer graphene, are materials generally formed by stacking two or more layers of 2D materials on top of each other with a small lattice mismatch. This slight mismatch creates a unique pattern known as the moiré pattern, which is associated with desirable optical and electronic properties.

The composition of the products varies depending on the starting materials. Pure methane reacts—with very low yield—to give ethane, propane and hydrogen. The addition of oxygen increases the conversion, resulting mainly in CO2 as well as CO, ethylene, and water.

In the presence of water, aqueous methane reacts to give acetone and tertiary butyl alcohol; in the gas phase, it gives ethane and propane. When both water and oxygen are added, the reactions are strongly accelerated. In the aqueous phase, formaldehyde, acetic acid, and acetone are formed. If ammonia is also added, acetic acid forms glycine, an amino acid also found in space.

“Under gamma radiation, glycine can be made from methane, oxygen, water, and ammonia, molecules that are found in large amounts in space,” says Huang. The team developed a reaction scheme that explains the routes by which the individual products are formed. Oxygen (∙O2−) and ∙OH radicals play an important role in this. The rates of these radical reaction mechanisms are not temperature-dependent and could thus also take place in space.

Advancements in nuclear physics may soon enable the creation of stable, superheavy nuclei, paving the way for new materials and insights into atomic stability.

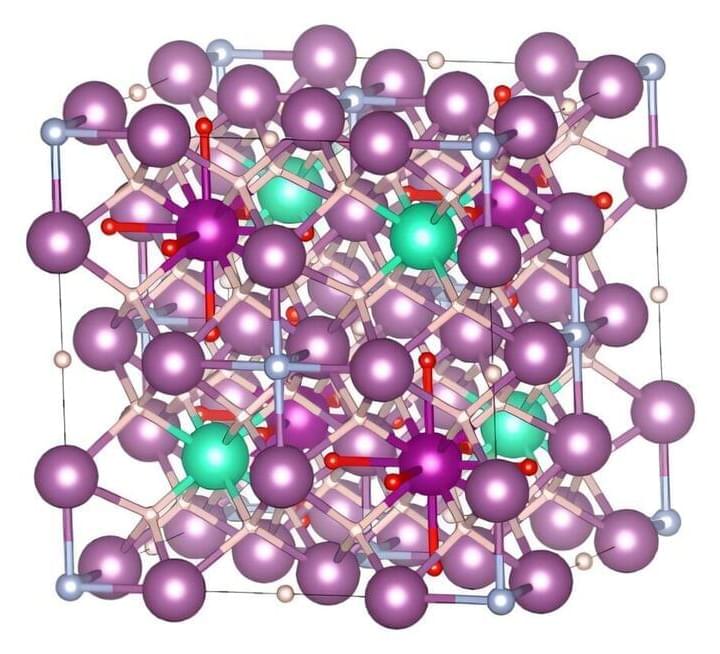

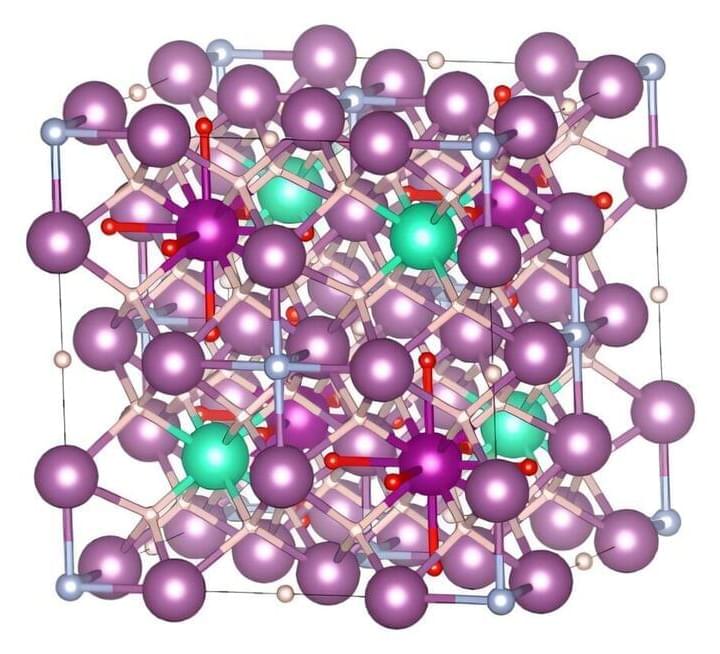

A team of scientists has made significant advancements in the quest to create new, long-lasting superheavy nuclei. These double magic nuclei, which have a precise number of protons and neutrons that form a highly stable configuration, are exceptionally resistant to decay. Their research could deepen our understanding of the forces that bind atoms and pave the way for the development of new materials with unique properties. This work brings us a step closer to the so-called “Island of Stability,” a theoretical region in the nuclei chart where it’s believed some nuclei could exist far longer than those created so far.

The study, led by Professor Feng-Shou Zhang, has predicted promising reactions between different elements that could be used in experiments to create double magic nuclei. One key discovery involves a reaction between a special type of radioactive calcium isotope and a plutonium target, which could produce the predicted double magic nuclei 298 Fl. Another potential double magic nuclei, 304 120, could be created by combining vanadium and berkelium, although this reaction is currently less likely to succeed.