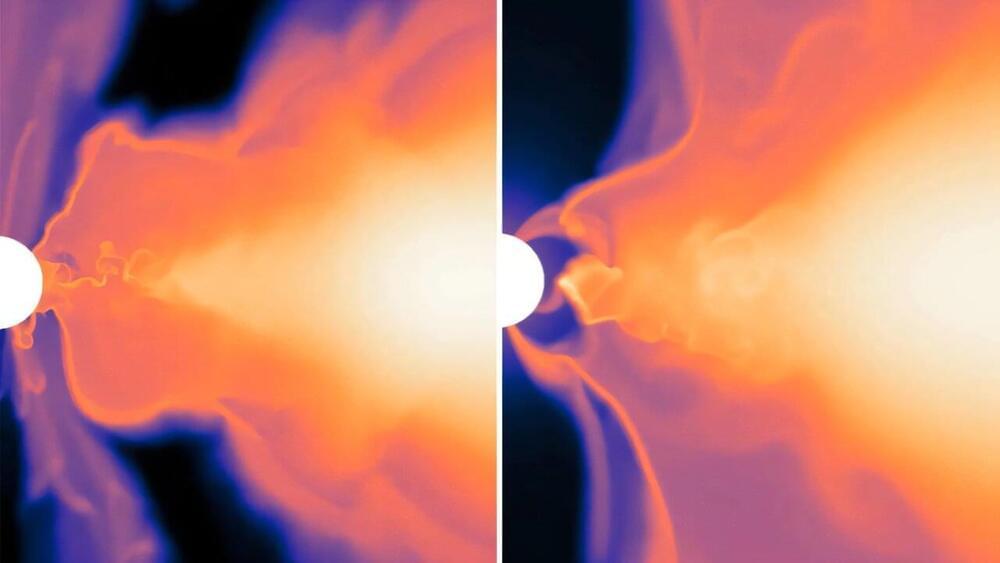

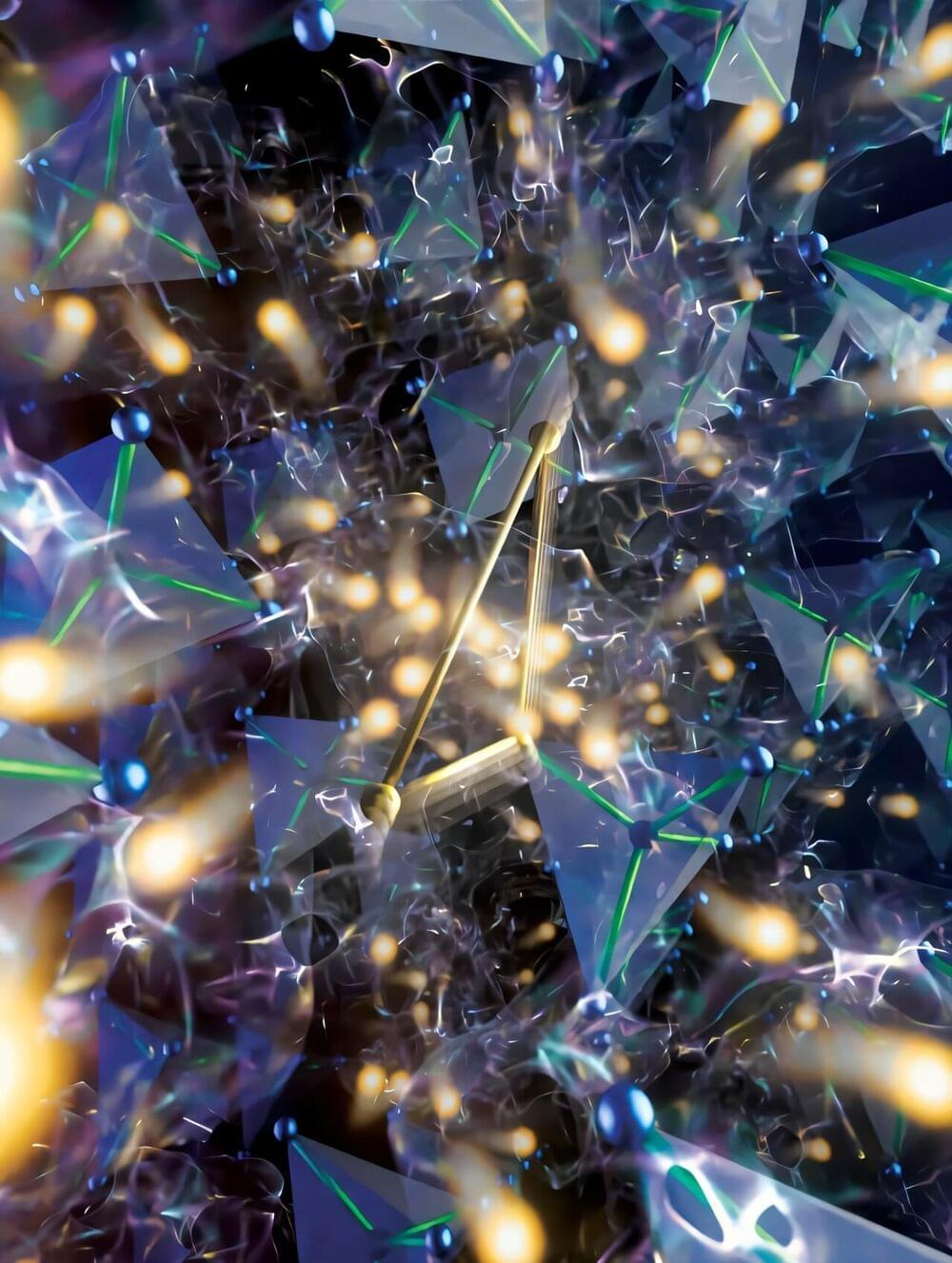

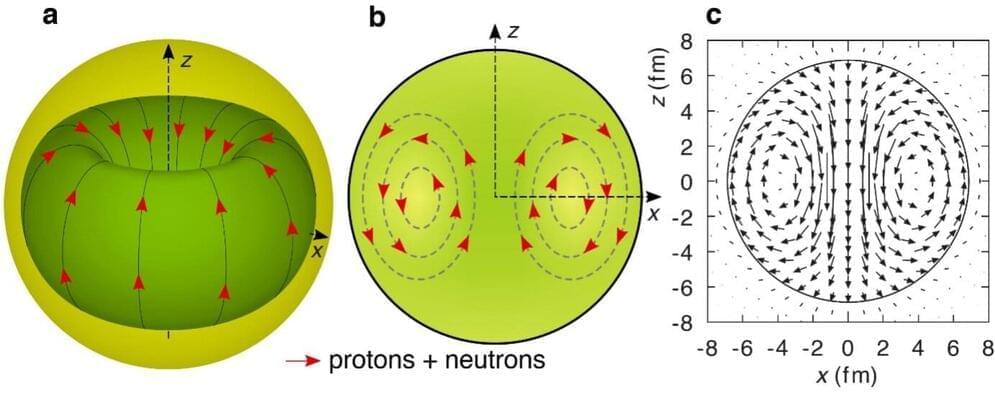

Dipole toroidal modes are a unique set of excitations that are predicted to occur in various physical systems, ranging from atomic nuclei to metamaterials. What characterizes these excitations, or modes, is a toroidal distribution of currents, which results in the formation of vortex-like structures.

A classic example is smoke rings, the characteristic “rings” of smoke produced when puffs of smoke are released into the air through a narrow opening. Physics theories have also predicted the existence of toroidal dipole excitations in atomic nuclei, yet observing these modes has so far proved challenging.

Researchers at Technische Universitat Darmstadt, the Joint Institute for Nuclear Research, and other institutes recently identified candidates for toroidal dipole excitations in the nucleus 58 Ni for the very first time. Their paper, published in Physical Review Letters, opens new possibilities for the experimental observations of these elusive modes in heavy nuclei.