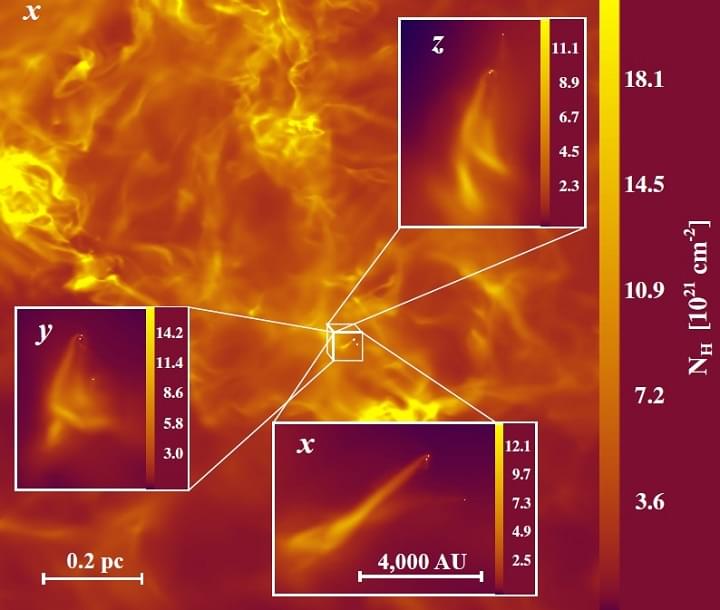

A study led by Paolo Padoan, ICREA research professor at the Institute of Cosmos Sciences of the University of Barcelona (ICCUB), is challenging the understanding of planetary disk formation around young stars.

The paper, published in Nature Astronomy, reveals that the environment plays a crucial role in determining the size and lifetime of these planetary disks, which are the sites of planet formation.

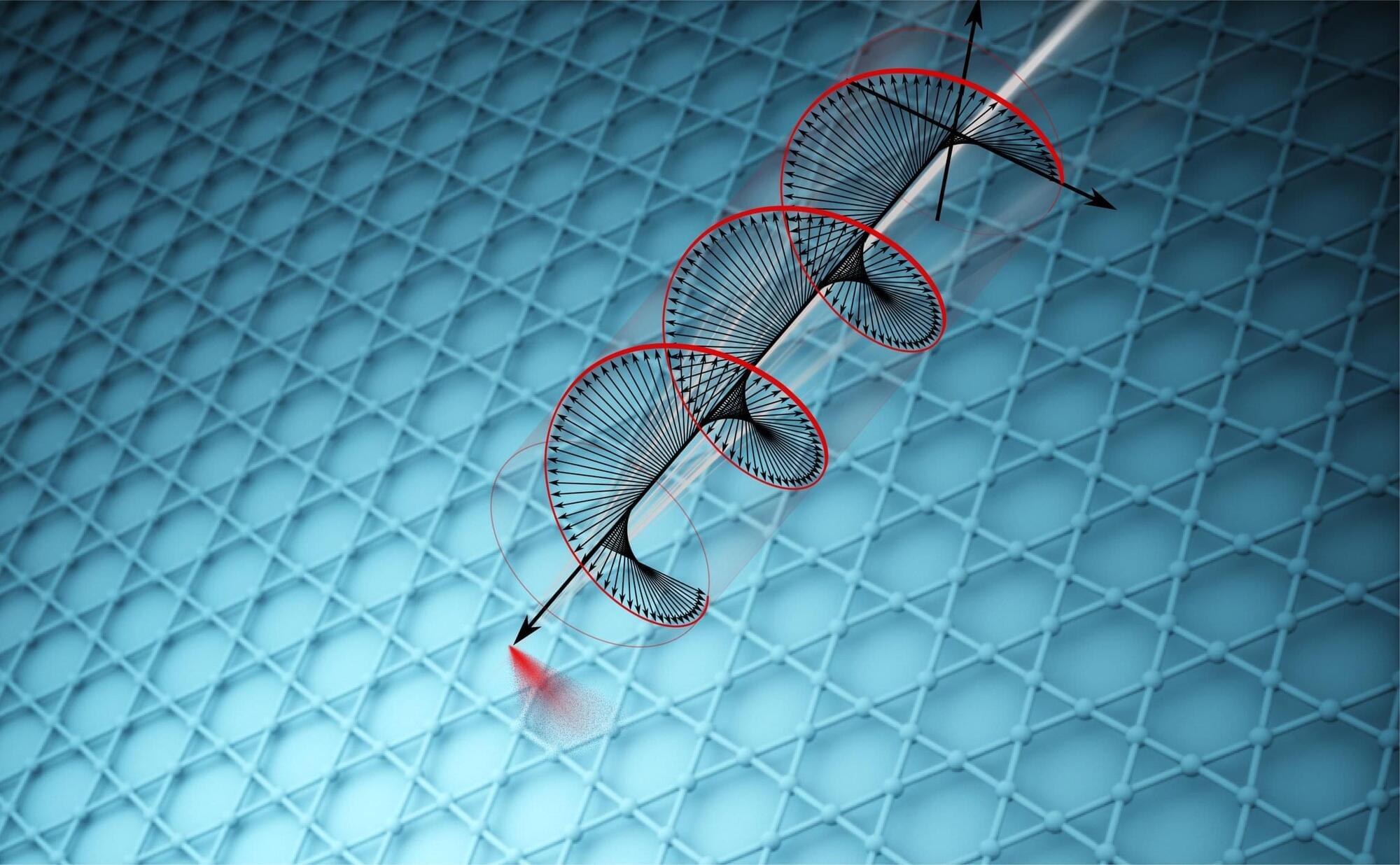

When a star forms, it is surrounded by a spinning disk of gas and dust. Over time, this material eventually forms the planets. Traditionally, scientists believed that once a disk forms, it simply loses too much over time as it feeds the star and the growing planets.