Gatebox’s Boku no Yome (“My Wife”) has been released in mass production for 150,000 yen (US$1,352). The holographic character stands about 8 inches tall and talks to her husband from behind a cylindrical plastic barrier. In addition to the upfront cost for Boku no Yome, husbands must pay a subscription fee of 1,500 yen (US$13.52) per month to keep their wife from getting outdated.

Category: materials – Page 342

Ocean Cleanup steams out to sea in test run to clean Great Pacific Garbage Patch

If all goes well, it will be towed out to the Great Pacific Garbage Patch nearly 1,400 miles off the West Coast, about halfway between California and Hawaii. A support vessel will fish out the collected plastic every few weeks, according to the Associated Press. The waste will then be transported to dry land for recycling.

Shipping containers filled with the collected plastic are expected back on land within a year.

The project is lauded by many as a positive attempt to deal with the growing problem of plastic pollution in the oceans.

Hierarchical 3D printing of nanoporous gold could ‘revolutionize’ electrochemical reactor design

Nanoporous metals are superior catalysts for chemical reactions due to their large surface area and high electrical conductivity, making them perfect candidates for applications such as electrochemical reactors, sensors and actuators.

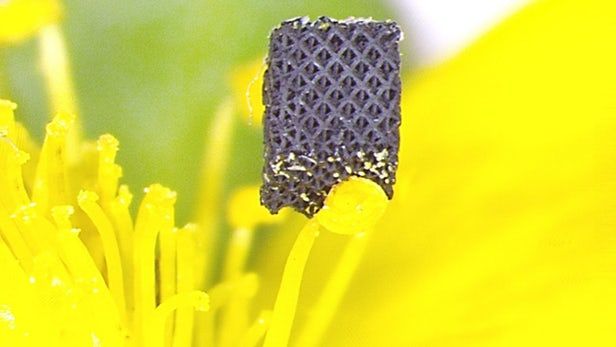

In a study published today in the journal Science Advances, Lawrence Livermore National Laboratory (LLNL) researchers, along with their counterparts at Harvard University, report on the hierarchical 3D printing of nanoporous gold, a proof of concept that researchers say could revolutionize the design of chemical reactors.

“If you consider traditional machining processes, it’s time consuming and you waste a lot of materials—also, you don’t have the capability to create complex structures,” said LLNL postdoctoral researcher Zhen Qi, a co-author on the paper. “By using 3D printing we can realize macroporous structures with application-specific flow patterns. By creating hierarchical structures, we provide pathways for fast mass transport to take full advantage of the large surface area of nanoporous materials. It’s also a way to save materials, especially precious metals.”

New 3D printing process paints graphene aerogel in far finer detail

Graphene is famous as a two-dimensional material, but to really make the most of the stuff we need to coax it back into 3D forms. Now researchers from Virginia Tech have developed a new way to 3D print graphene aerogels with a far higher resolution than previously possible.

Researchers are developing fast-charging solid-state batteries

Solid-state batteries contain no liquid parts that could leak or catch fire. For this reason, they do not require cooling, and are considered to be much safer, more reliable, and longer lasting than traditional lithium-ion batteries. Juelich scientists have now introduced a new concept that allows currents up to 10 times greater during charging and discharging than previously described in the literature.

Low current is considered one of the biggest hurdles in the development of solid-state batteries because the batteries take a relatively long time to charge, usually about 10 to 12 hours in the case of a fully discharged battery. The new cell type that Jülich scientists have designed, however, takes less than an hour to recharge.

“With the concepts described to date, only very small charge and discharge currents were possible due to problems at the internal solid-state interfaces. This is where our concept based on a favourable combination of materials comes into play, and we have already patented it,” explains Dr. Hermann Tempel, group leader at the Juelich Institute for Energy and Climate Research (IEK-9).

Stacking concrete blocks is a surprisingly efficient way to store energy

To deal with variable solar and wind power, the startup Energy Vault is coming out of stealth mode to offer alternatives to lithium-ion batteries.

Institute for Advanced Studies At Austin

The ADAM Research Project, an acronym for Acquisition & Data Analysis of Materials, will focus on the collection and scientific evaluation of material samples obtained through reliable reports of advanced aerospace vehicles of unknown origin.

As a first step, TTS Academy has established a contract with EarthTech International, Inc., (www.earthtech.org) a well-respected research think tank in Austin, Texas, to evaluate the properties of the available materials. Under the leadership of Dr. Harold E. Puthoff, a former Senior Advisor and Subcontractor to the Pentagonfs AATIP program (Advanced Aerospace Threat Identification Program) and current VP of Technology for TTS Academy, EarthTech is well-positioned to head up this materials research plan.