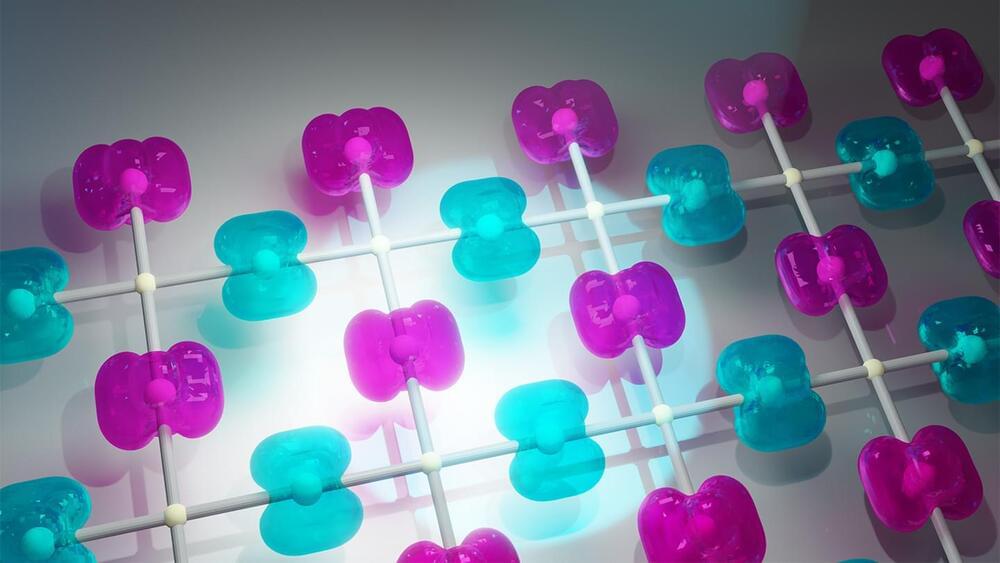

Researchers have discovered an extraordinary metal alloy that won’t crack at extreme temperatures due to kinking, or bending, of crystals in the alloy at the atomic level.

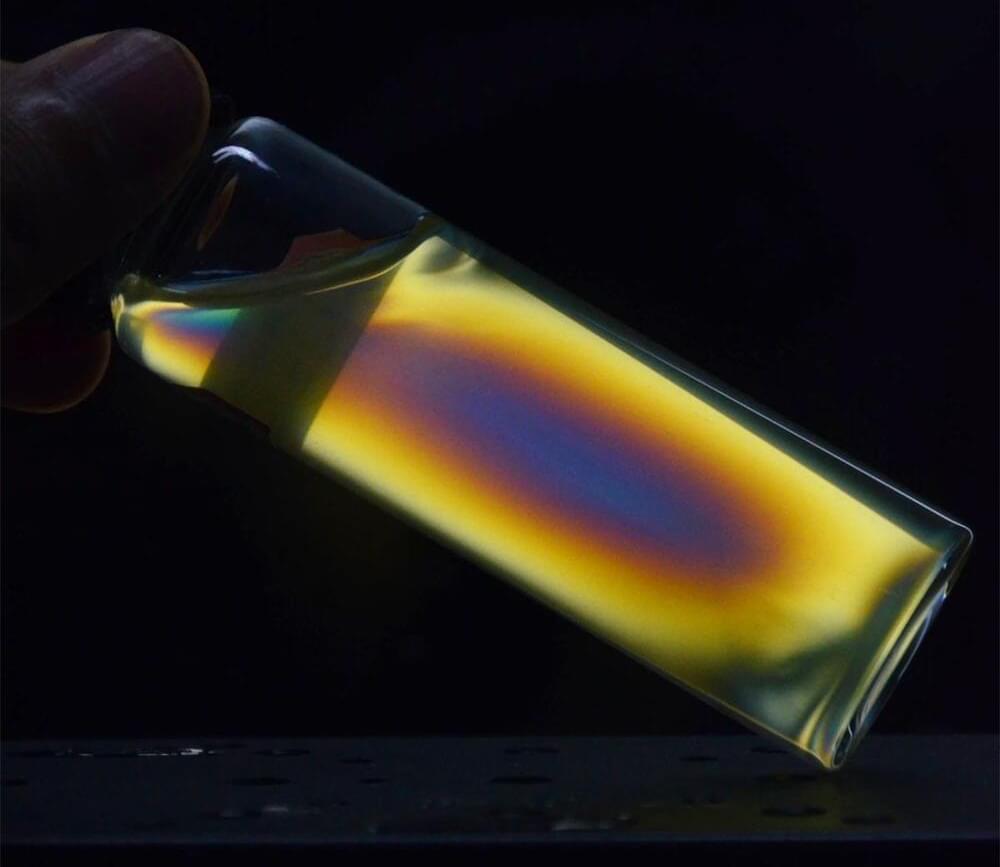

A metal alloy composed of niobium, tantalum, titanium, and hafnium has shocked materials scientists with its impressive strength and toughness at both extremely hot and cold temperatures, a combination of properties that seemed so far to be nearly impossible to achieve. In this context, strength is defined as how much force a material can withstand before it is permanently deformed from its original shape, and toughness is its resistance to fracturing (cracking). The alloy’s resilience to bending and fracture across an enormous range of conditions could open the door for a novel class of materials for next-generation engines that can operate at higher efficiencies.

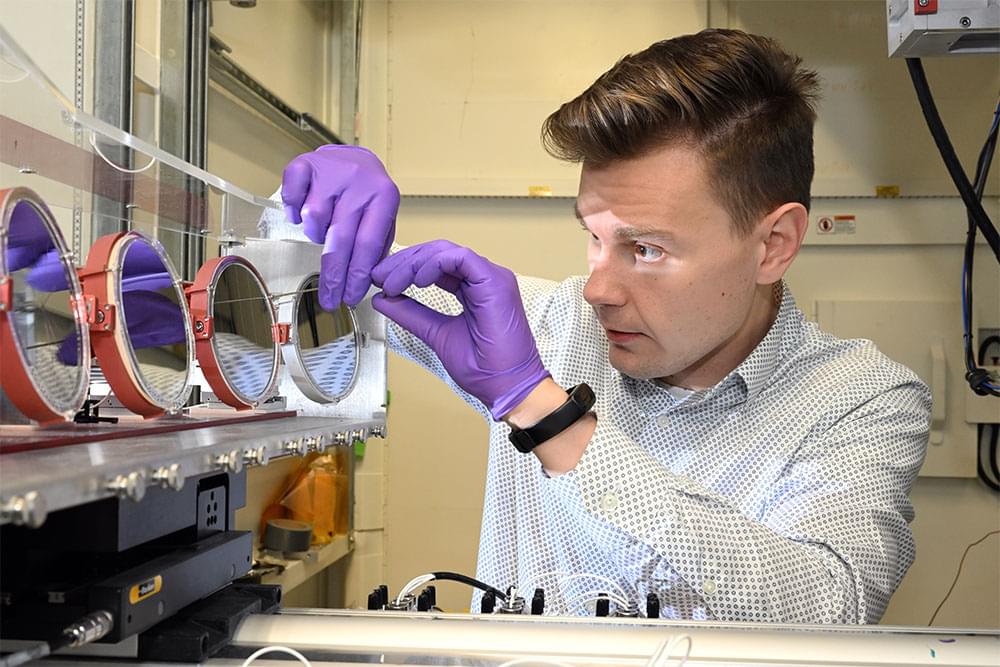

The team, led by Robert Ritchie at Lawrence Berkeley National Laboratory (Berkeley Lab) and UC Berkeley, in collaboration with the groups led by professors Diran Apelian at UC Irvine and Enrique Lavernia at Texas A&M University, discovered the alloy’s surprising properties and then figured out how they arise from interactions in the atomic structure. Their work is described in a study recently published in the journal Science.