Welcome to the age of wireless electricity.

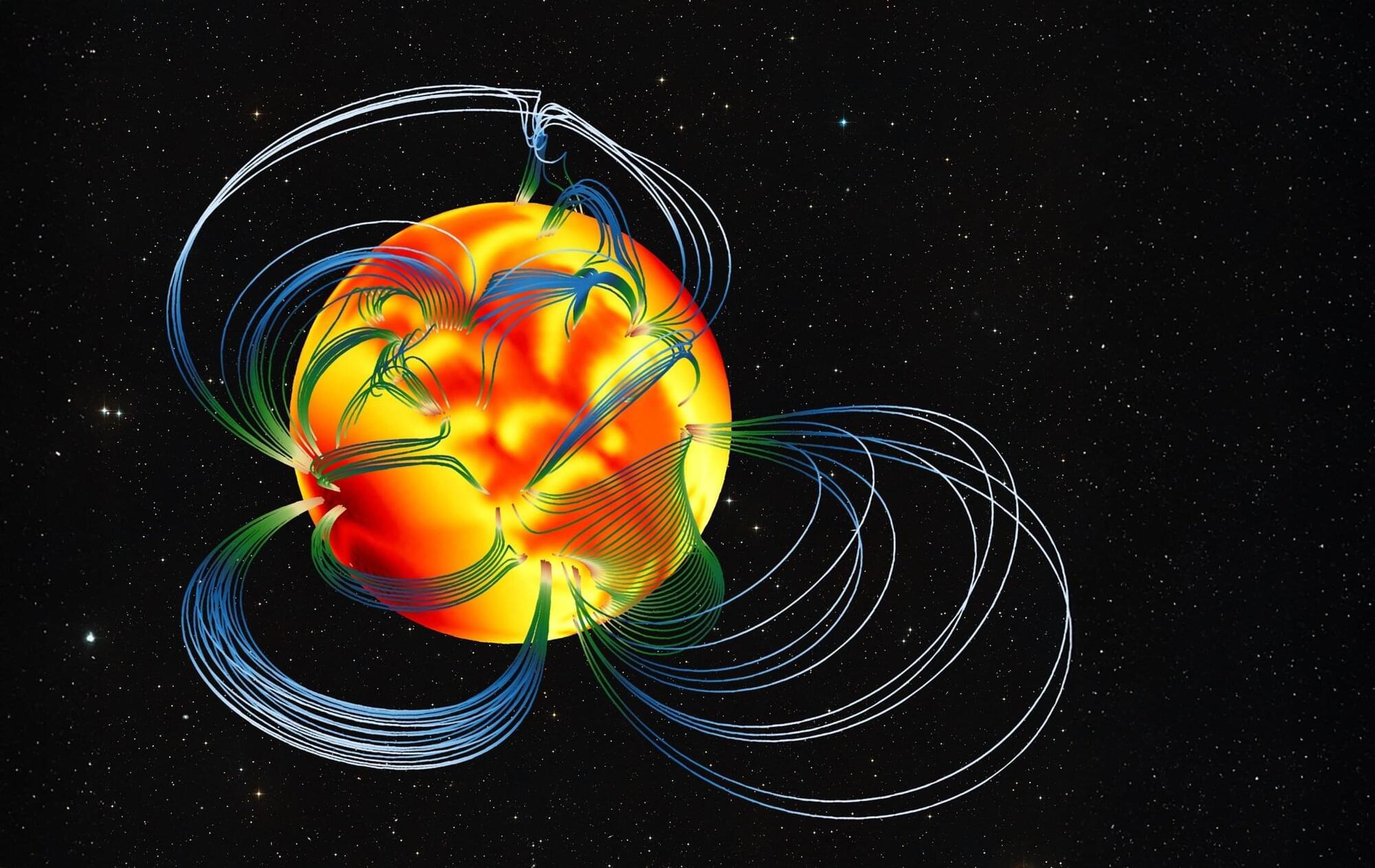

Nikola Tesla once envisioned a world where electricity could be transmitted wirelessly, eliminating the need for wires and revolutionizing energy distribution.

Over a century later, that dream is on the brink of becoming reality.

Companies worldwide, from America’s Wave Inc. to Japan’s Space Power Technologies and New Zealand’s Emrod, are pioneering wireless power transmission technologies. These innovations range from microwave and laser-based energy transfer to solar satellites that beam electricity from space. New Zealand is already testing Emrod’s wireless energy infrastructure, which could provide clean, sustainable power across difficult terrains. Meanwhile, advancements like wireless EV charging roads and underground charging systems are making the technology more practical than ever.

As promising as wireless electricity sounds, challenges remain—chief among them, public skepticism and efficiency concerns.

Despite this, major institutions like Caltech and Purdue University are pushing forward, with projects aimed at developing large-scale wireless power solutions. Whether through inductive charging for electric vehicles, space-based solar power, or rectenna-driven energy grids, the world is inching closer to Tesla’s vision. If successful, wireless electricity could revolutionize industries, eliminate the limitations of traditional power grids, and usher in a new era of energy sustainability.

The future of power might just be as simple as turning on a switch—without plugging in.