Australian Research opens up new possibilities for hydrogen fuelled future.

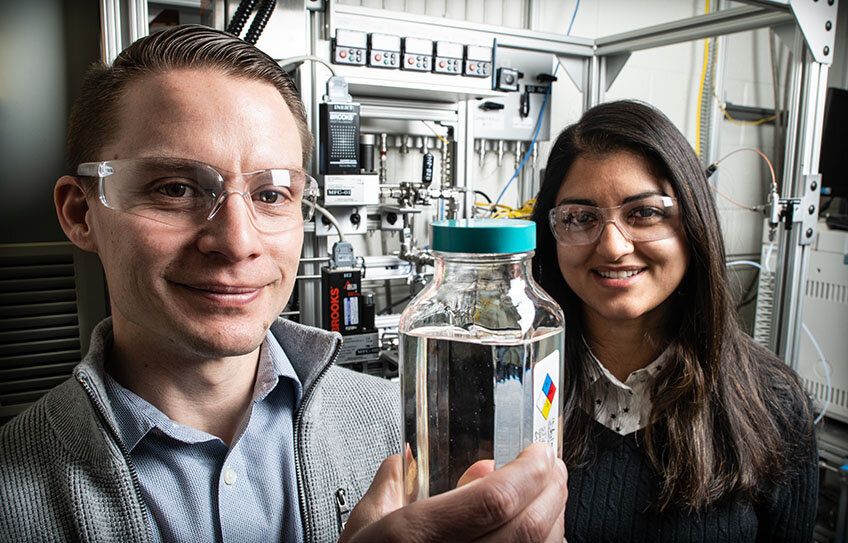

Scientists show how using only water, iron, nickel and electricity can create hydrogen energy much more cheaply than before.

Hydrogen-powered cars may soon become more than just a novelty after a UNSW-led team of scientists demonstrated a much cheaper and sustainable way to create the hydrogen required to power them.

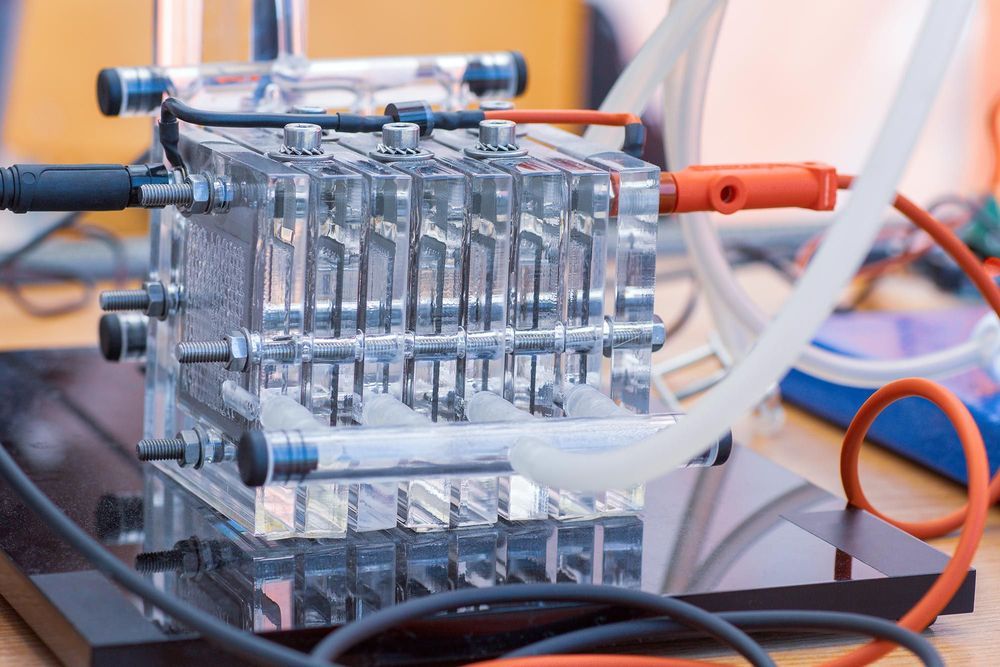

In research published in Nature Communications recently, scientists from UNSW Sydney, Griffith University and Swinburne University of Technology showed that capturing hydrogen by splitting it from oxygen in water can be achieved by using low-cost metals like iron and nickel as catalysts, which speed up this chemical reaction while requiring less energy.