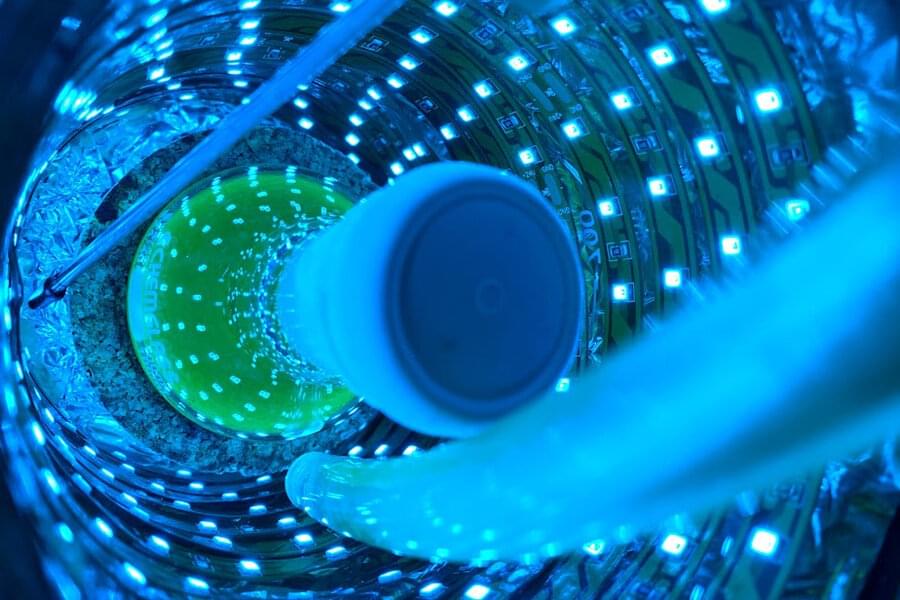

One of the myriad issues with hydrogen as a clean energy source is infrastructure, as it’s very expensive to move around and store an extremely explosive gas. Toyota and its subsidiary Woven Planet believe they may have a solution with a new portable hydrogen cartridge prototype. The idea is that they can be filled up at a dedicated facility, transported where needed, then returned when you receive your next shipment.

The cartridges would be relatively small at 16 inches long, 7 inches in diameter and about 11 pounds in weight. Toyota calls them “portable, affordable, and convenient energy that makes it possible to bring hydrogen to where people live, work, and play without the use of pipes… [and] swappable for easy replacement and quick charging.”

They could be useful for “mobility [i.e. hydrogen cars], household applications, and many future possibilities we have yet to imagine,” Toyota said. It didn’t mention any specific uses, but it said that “one hydrogen cartridge is assumed to generate enough electricity to operate a typical household microwave for approximately 3–4 hours.”