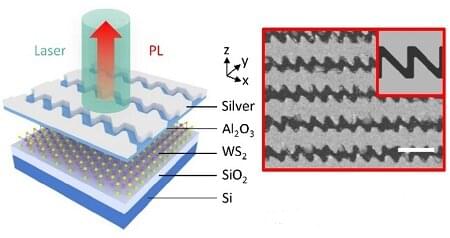

Scientists at the University of Groningen used a silver sawtooth nanoslit array to produce valley-coherent photoluminescence in two-dimensional tungsten disulfide flakes at room temperature. Until now, this could only be achieved at very low temperatures. Coherent light can be used to store or transfer information in quantum electronics. This plasmon-exciton hybrid device is promising for use in integrated nanophotonics (light-based electronics). The results were published in Nature Communications on 5 February.

Tungsten disulfide has interesting electronic properties and is available as a 2-D material. “The electronic structure of monolayer tungsten disulfide shows two sets of lowest energy points or valleys,” explains Associate Professor Justin Ye, head of the Device Physics of Complex Materials group at the University of Groningen. One possible application is in photonics, as it can emit light with valley-dependent circular polarization—a new degree of freedom to manipulate information. However, valleytronics requires coherent and polarized light. Unfortunately, previous work showed that photoluminescence polarization in tungsten disulfide is almost random at room temperature.