A radio signal tells the components to vaporize.

No cameras needed to keep an eye on your home.

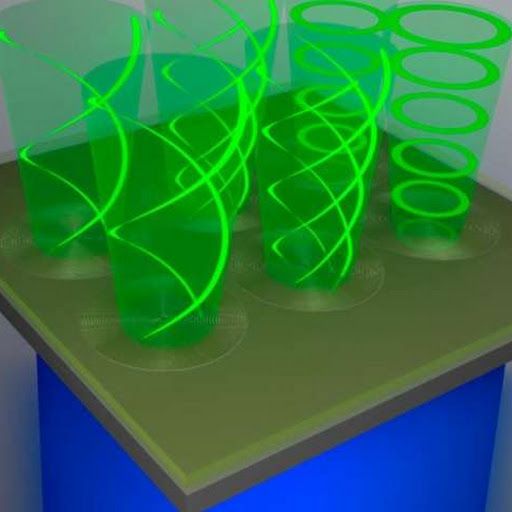

Illustration of an array of organic vortex lasers, each with a different spiral and therefore a different topological charge. Credit: Stellinga et al. ©2018 American Chemical Society Researchers have developed a new type of organic vortex laser, which is a laser that emits a helical beam of light. In the future, miniature arrays of these vortex lasers, each with a slightly different spiral shape, may be used in applications such as 3D TV displays, microscopy, and as information carriers for visible light communications. The researchers, led by Ifor D. W. Samuel at the University of St. Andr…

By Jeffrey Dastin

SEATTLE (Reuters) — Amazon.com Inc will open its checkout-free grocery store to the public on Monday after more than a year of testing, the company said, moving forward on an experiment that could dramatically alter brick-and-mortar retail.

The Seattle store, known as Amazon Go, relies on cameras and sensors to track what shoppers remove from the shelves, and what they put back. Cash registers and checkout lines become superfluous — customers are billed after leaving the store using credit cards on file.

The future of clothing unfolds at this year’s Consumer Electronics Show with the unveiling of an e-ink dress and much more!

With CES 2018 now in full swing, it’s time to explore what Intel, Samsung, Toyota, and other companies have in store for the future of consumer electronics.

The 2018 Consumer Electronics Show is now in full swing. Between now and Friday, January 12, all kinds of technology — both conceptual and practical — will be unveiled and trotted out in front of audiences. We’ve already written about what you can expect to see from CES 2018, but as day one draws to a close, it’s a good time to check-in on what’s already trending.

And you thought that 65-inch TV you just bought was big? Sorry, friend.

Contact-free measurement of vital signs is already a reality, but with a few important limitations some of which researchers at Cornell University may be able to overcome. Currently used devices typically require the patient to be in close proximity to the sensor, and they’re only able to measure the breathing and heart rates, along with body movement.

Technology developed at Cornell involves tags worn on clothing, or just placed near the patient, that emit radio waves toward the lungs and heart to measure their activity accurately, while allowing the patient to move around. Additionally, blood pressure may also be measured this way, but more work will be required to validate the technology.

The new technique relies on so-called near-field coherent sensing, which allows each tag to have a unique radio signal. This permits many patients in the same facility to be monitored uniquely and without any interference.