The daily figure in Tokyo grew by 8,537 from a week earlier to 16,878, marking a week-on-week increase for the 26th straight day.

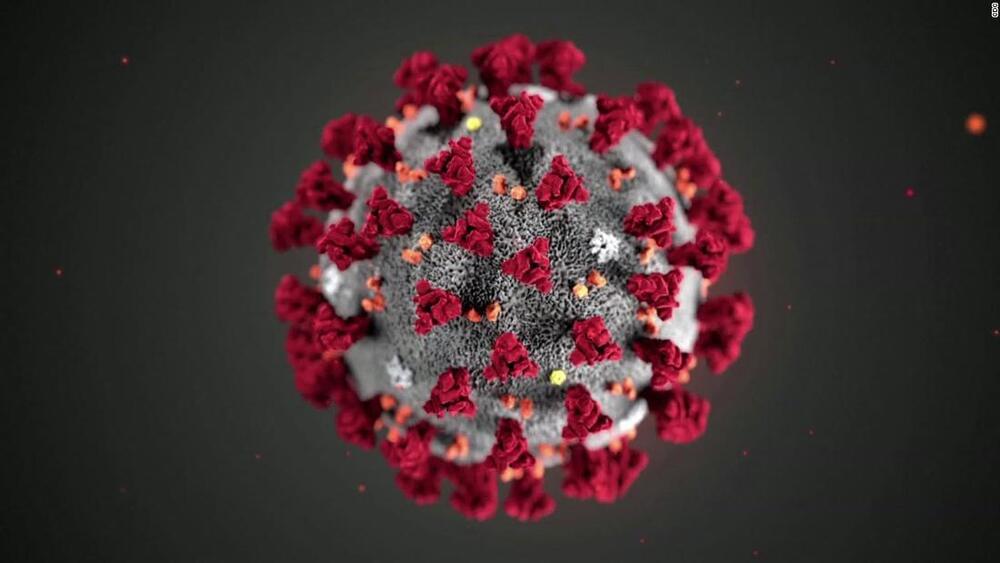

Nearly two-and-a-half years since the coronavirus pandemic began, the most infectious and transmissible variant yet has arrived.

Repeated Covid-19 waves have left millions of people dead, with only vaccines helping to blunt the toll. Now the virus is spreading again — evolving, escaping immunity and driving an uptick in cases and hospitalizations. The latest version of its shape-shifting, BA.5, is a clear sign that the pandemic is far from over.

The newest offshoot of Omicron, along with a closely related variant, BA.4, are fueling a global surge in cases — 30% over the past fortnight, according to the World Health Organization (WHO).

Engineers have developed a new class of smart textiles that can shape-shift and turn a two-dimensional material into 3D structures.

The team from UNSW Sydney’s Graduate School of Biomedical Engineering, and Tyree Foundation Institute of Health Engineering (Tyree iHealthE), led by Dr. Thanh Nho Do, have produced a material which is constructed from tiny soft artificial “muscles”—which are long silicon tubes filled with fluid which are manipulated to move via hydraulics.

These artificial muscles, which are surrounded by a helical coil of traditional fibers, can be programmed to contract or expand into a variety of shapes depending on its initial structure.

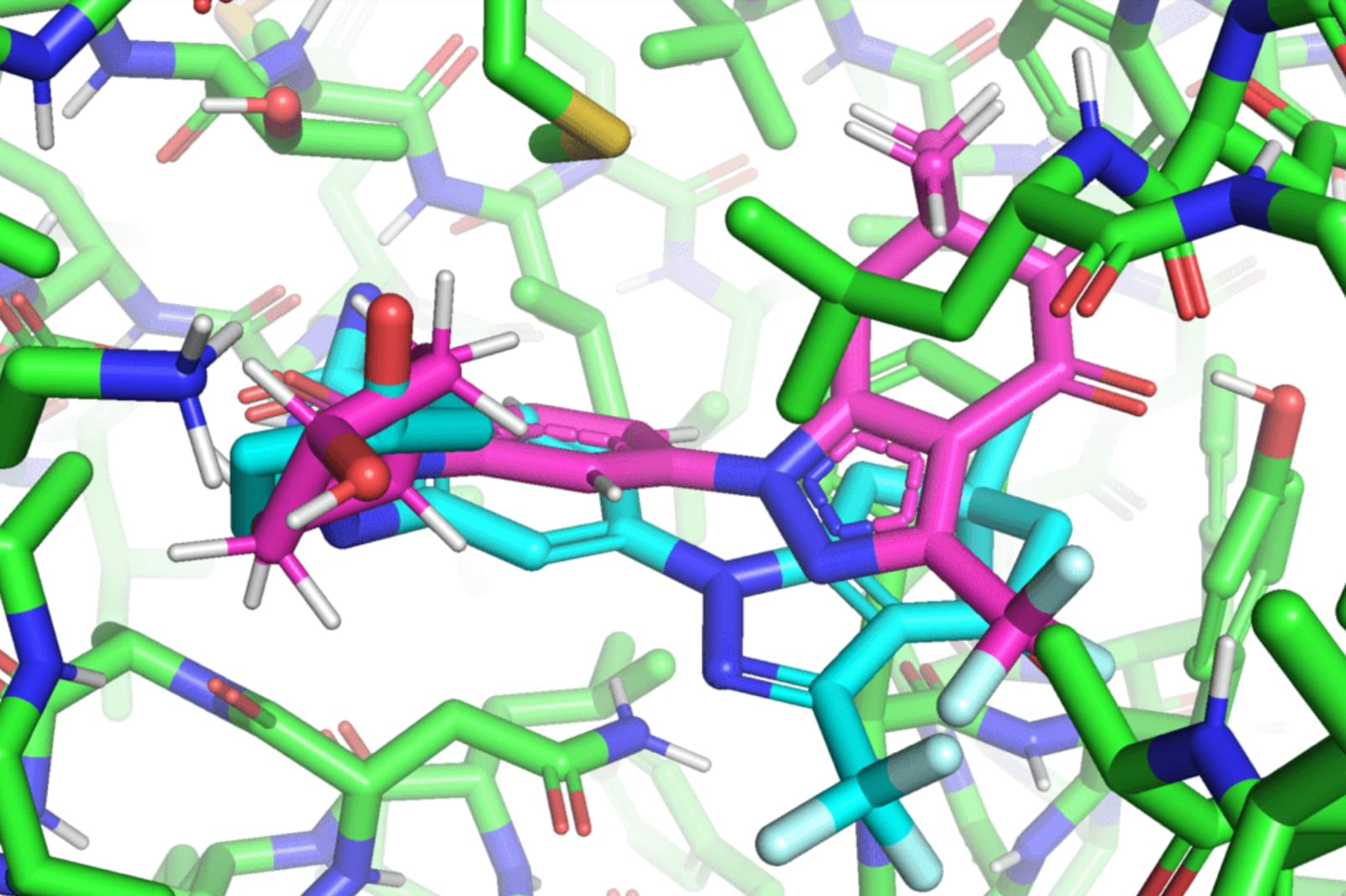

The entirety of the known universe is teeming with an infinite number of molecules. But what fraction of these molecules have potential drug-like traits that can be used to develop life-saving drug treatments? Millions? Billions? Trillions? The answer: novemdecillion, or 1060. This gargantuan number prolongs the drug development process for fast-spreading diseases like COVID-19 because it is far beyond what existing drug design models can compute. To put it into perspective, the Milky Way has about 100 thousand million, or 108, stars.

In a paper that will be presented at the International Conference on Machine Learning (ICML), MIT researchers developed a geometric deep-learning model called EquiBind that is 1,200 times faster than one of the fastest existing computational molecular docking models, QuickVina2-W, in successfully binding drug-like molecules to proteins. EquiBind is based on its predecessor, EquiDock, which specializes in binding two proteins using a technique developed by the late Octavian-Eugen Ganea, a recent MIT Computer Science and Artificial Intelligence Laboratory and Abdul Latif Jameel Clinic for Machine Learning in Health (Jameel Clinic) postdoc, who also co-authored the EquiBind paper.

Before drug development can even take place, drug researchers must find promising drug-like molecules that can bind or “dock” properly onto certain protein targets in a process known as drug discovery. After successfully docking to the protein, the binding drug, also known as the ligand, can stop a protein from functioning. If this happens to an essential protein of a bacterium, it can kill the bacterium, conferring protection to the human body.

While many artificial materials have advanced properties, they have a long way to go to combine the versatility and functionality of living materials that can adapt to their situation. For example, in the human body bone and muscle continuously reorganise their structure and composition to better sustain changing weight and level of activity.

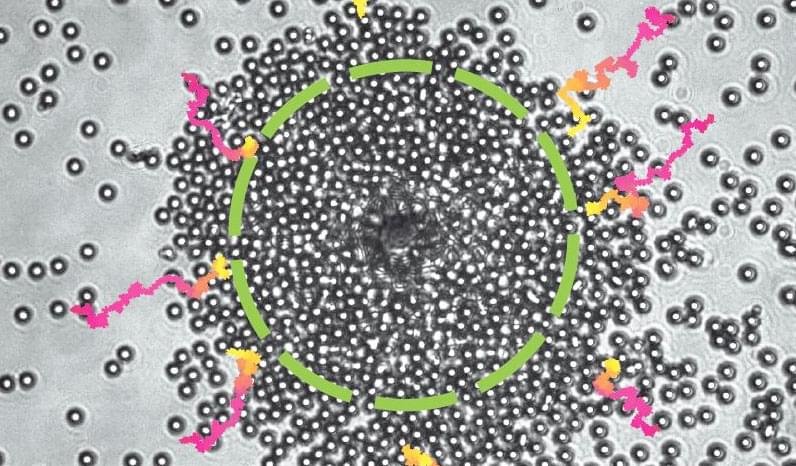

Now, researchers from Imperial College London and University College London have demonstrated the first spontaneously self-organising laser device, which can reconfigure when conditions change.

The innovation, reported in Nature Physics (“Self-organized Lasers of Reconfigurable Colloidal Assemblies”), will help enable the development of smart photonic materials capable of better mimicking properties of biological matter, such as responsiveness, adaptation, self-healing, and collective behaviour.

The team of researchers who transplanted a genetically modified pig’s heart into a living human earlier this year have completed two more pig heart transplant surgeries, setting the protocol for such operations.

In January this year, 57-year-old David Bennett became the first man on the planet to receive a heart from a genetically modified pig. Before this, researchers transplanted kidneys from similarly modified pigs into patients that were brain dead.

The organs are sourced from a company called Revivicor which uses genetic engineering to remove specific genes in the pigs to help in reducing transplant rejection while adding some that make the organs more compatible with the human immune system.

The Neuro-Network.

𝐆𝐥𝐨𝐛𝐚𝐥 𝐭𝐞𝐚𝐦 𝐨𝐟 𝐬𝐜𝐢𝐞𝐧𝐭𝐢𝐬𝐭𝐬 𝐝𝐢𝐬𝐜𝐨𝐯𝐞𝐫 𝐧𝐞𝐰 𝐠𝐞𝐧𝐞 𝐜𝐚𝐮𝐬𝐢𝐧𝐠 𝐬𝐞𝐯𝐞𝐫𝐞 𝐧𝐞𝐮𝐫𝐨𝐝𝐞𝐯𝐞𝐥𝐨𝐩𝐦𝐞𝐧𝐭𝐚𝐥 𝐝𝐞𝐥𝐚𝐲𝐬

𝘼𝙣 𝙞𝙣𝙩𝙚𝙧𝙣𝙖𝙩𝙞𝙤𝙣𝙖𝙡 𝙩𝙚𝙖𝙢 𝙤𝙛 𝙧𝙚𝙨𝙚𝙖𝙧𝙘𝙝𝙚𝙧𝙨 𝙡𝙚𝙙 𝙗𝙮 𝙐𝘾 𝘿𝙖𝙫𝙞𝙨 𝙜𝙚𝙣𝙚𝙩𝙞𝙘𝙞𝙨𝙩 𝙎𝙪𝙢𝙖 𝙎𝙝𝙖𝙣𝙠𝙖… See more.

An international team of researchers led by UC Davis geneticist Suma Shankar has discovered a new gene implicated in a neurodevelopmental condition called DPH5-related diphthamide-deficiency syndrome. The syndrome is caused by DPH5 gene variants that may lead to embryonic death or profound neurodevelopmental delays.

Findings from their study were published in Genetics in Medicine.

“We are so excited about the novel gene discovery,” said the lead author Suma Shankar, professor in the Departments of Pediatrics and Ophthalmology and faculty at the UC Davis MIND Institute. Shankar is the director of Precision Genomics, Albert Rowe Endowed Chair in Genetics, and chief of Division of Genomic Medicine.