Researchers have created “sponges” that would absorb excess cancer drugs before they spread through the body and cause negative side effects.

Spinal cord injuries (SCIs) affect approximately 300,000 Americans, with about 18,000 new cases occurring per year. One of these patients, Jake Javier, who we have written about many times over the past several years, received ten million stem cells as part of a CIRM-funded clinical trial and a video about his first year at Cal Poly depicts how these injuries can impact someone’s life.

Currently, there is nothing that completely reverses SCI damage and most treatment is aimed at rehabilitation and empowering patients to lead as normal a life as possible under the circumstances. Improved treatment options are necessary both to improve patients’ overall quality of life, and to reduce associated healthcare costs.

Scientists at UC San Diego’s School of Medicine and Institute of Engineering in Medicine have made critical progress in providing SCI patients with hope towards a more comprehensive and longer lasting treatment option.

The texture of an artist’s original work can now be reproduced with AI-controlled 3D printing.

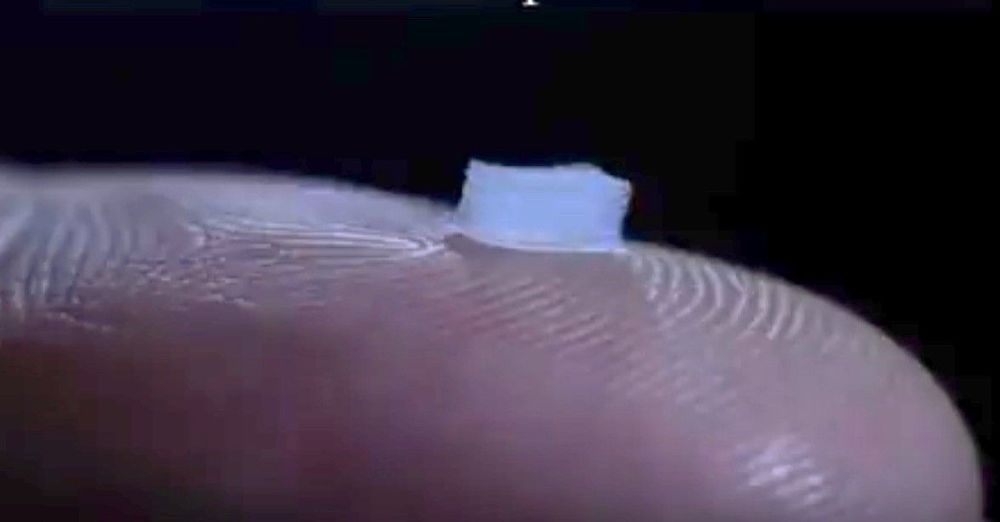

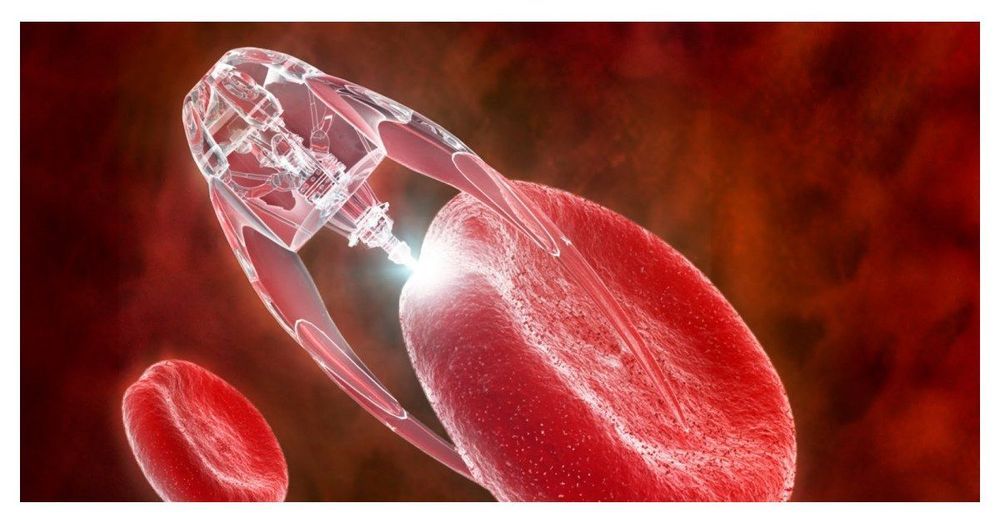

Engineers at the University of Maryland (UMD) have created the first 3D-printed fluid circuit element so tiny that 10 could rest on the width of a human hair. The diode ensures fluids move in only a single direction—a critical feature for products like implantable devices that release therapies directly into the body.

Aether collaborating with University College London and Loughborough University to develop 3D printing nanotechnology at a revolutionary low cost.

Erin Abbott [email protected]

The piezoelectric materials that inhabit everything from our cell phones to musical greeting cards may be getting an upgrade thanks to work discussed in the journal Nature Materials released online Jan 21.

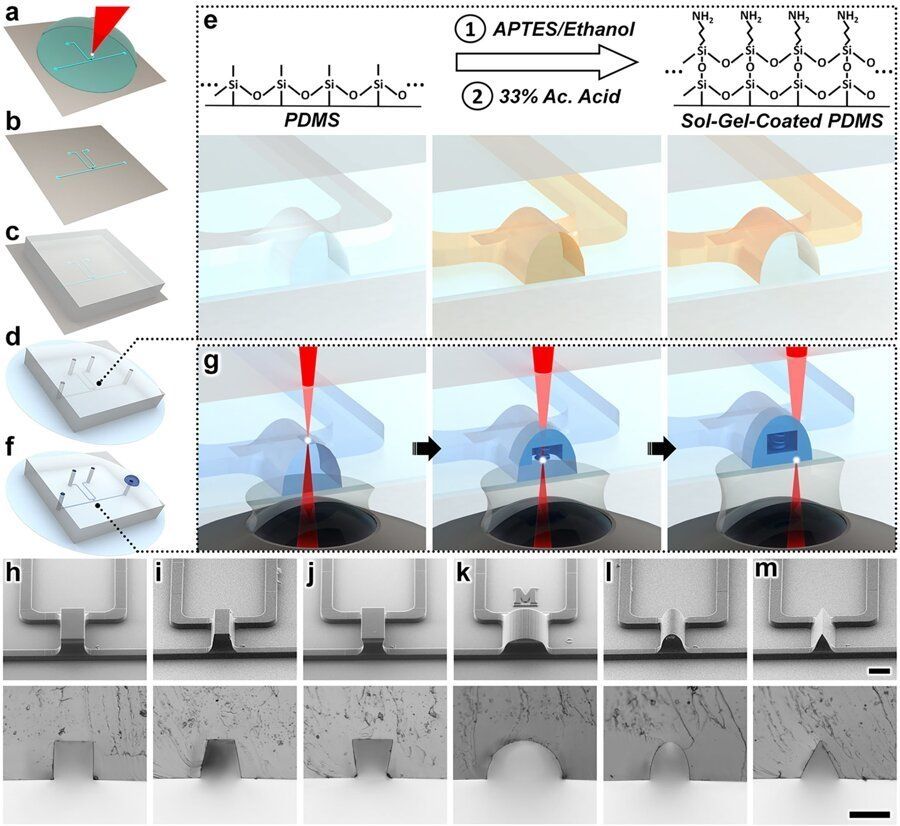

New research from MIT has resulted in a microfluidic device, the tumor analysis platform (TAP), that can simulate different cancer treatments on biopsied tumor tissue. The TAP device can be 3D printed within one hour and is slightly larger than a quarter. Three cylindrical shafts rise from the surface of the device and serve as ports to input and drain fluids, as well as remove air bubbles. Fluid—including various media, fluorescent markers, or lymphocytes—gets injected into an inlet port adjacent to the trap. The fluid enters through the inlet port and flows past the trap.

A new 3D-printed device from MIT researchers allows for the testing of different cancer treatments on live tumor tissue outside the human body.

Researchers with the University of Michigan have developed a new 3D printing technology that is capable of printing 100 times faster than normal 3D printers. Unlike traditional 3D printers, which work by applying plastic down as layers, the new technology involves resin that is solidified upward at rapid speeds. The new method is capable of producing complex objects at speeds that traditional printers can’t compete with.