Researchers at the University of Michigan have invented a new method of 3D printing which is up to 100 times faster than conventional existing 3D-printing processes. Here’s how it works, and why it could prove a game-changer for the way that 3D printing is currently used.

Category: 3D printing – Page 85

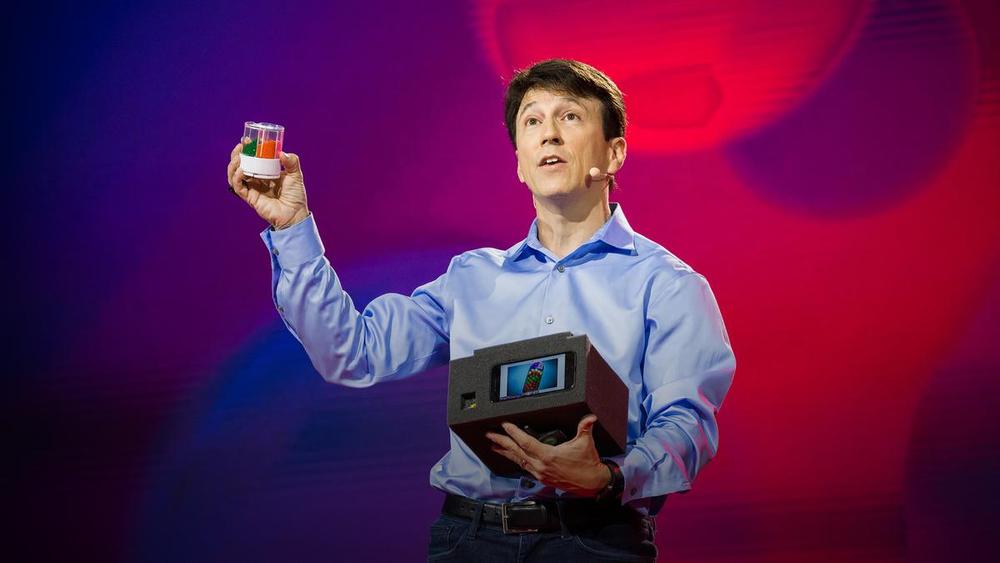

The pharmacy of the future? Personalized pills, 3D printed at home

We need to change how we prescribe drugs, says physician Daniel Kraft: too often, medications are dosed incorrectly, cause toxic side effects or just don’t work. In a talk and concept demo, Kraft shares his vision for a future of personalized medication, unveiling a prototype 3D printer that could design pills that adapt to our individual needs.

Military hopes 3D printing bones can help combat veterans’ injuries

TUCSON, Ariz. – A lab in Arizona is hoping to help wounded veterans – through 3D printing.

Arizona’s Orthopedic Research Lab is hoping to use the technology to help military veterans with bone injuries.

Dr. John Szivek, who runs the University of Arizona Orthopaedic Research Lab, said the lab received a $2 million grant from the Department of Defense to create 3D bone printing to help military personnel.

“Bionic Mushrooms” Fuse Nanotech, Bacteria and Fungi

(Hoboken, N.J. — Nov. 7, 2018) — In their latest feat of engineering, researchers at Stevens Institute of Technology have taken an ordinary white button mushroom from a grocery store and made it bionic, supercharging it with 3D-printed clusters of cyanobacteria that generate electricity and swirls of graphene nanoribbons that can collect the current.

The work, reported in the Nov. 7 issue of Nano Letters, may sound like something straight out of Alice in Wonderland, but the hybrids are part of a broader effort to better improve our understanding of cells biological machinery and how to use those intricate molecular gears and levers to fabricate new technologies and useful systems for defense, healthcare and the environment.

“In this case, our system – this bionic mushroom — produces electricity,” said Manu Mannoor, an assistant professor of mechanical engineering at Stevens. “By integrating cyanobacteria that can produce electricity, with nanoscale materials capable of collecting the current, we were able to better access the unique properties of both, augment them, and create an entirely new functional bionic system.”

Singularity Hub’s Top Articles of the Year

As 2018 draws to a close and we start anticipating the developments that will happen in 2019, here’s a look back at our ten most-read articles of the year.

This 3D Printed House Goes Up in a Day for Under $10,000 Vanessa Bates Ramirez | 3/18/18 “ICON and New Story’s vision is one of 3D printed houses acting as a safe, affordable housing alternative for people in need. New Story has already built over 800 homes in Haiti, El Salvador, Bolivia, and Mexico, partnering with the communities they serve to hire local labor and purchase local materials rather than shipping everything in from abroad.”

Machines Teaching Each Other Could Be the Biggest Exponential Trend in AI Aaron Frank | 1/21/18 “Data is the fuel of machine learning, but even for machines, some data is hard to get—it may be risky, slow, rare, or expensive. In those cases, machines can share experiences or create synthetic experiences for each other to augment or replace data. It turns out that this is not a minor effect, it actually is self-amplifying, and therefore exponential.”

Understanding 3D Printing Tolerances for Engineering Fits

In Tutorials

Tolerance and fit are essential concepts for any engineer designing mechanical assemblies.

Accounting for tolerances ultimately optimizes both the prototyping and production processes, reducing the material cost of iteration, lowering post-processing time, and mitigating the risk of accidentally broken parts.

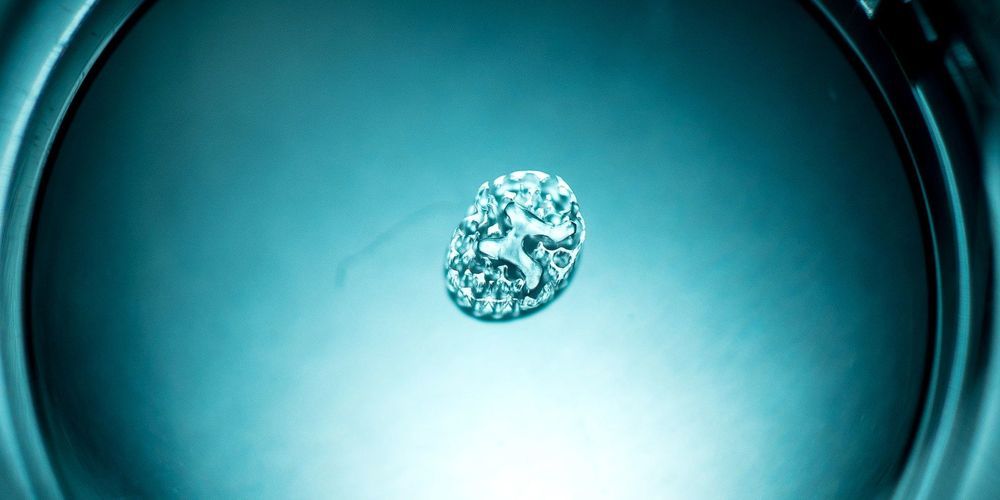

United Therapeutics to Develop CollPlant Technologies for 3D Bioprinted Lung Transplants

United Therapeutics will license, develop, and commercialize CollPlant Holdings’ recombinant human collagen (rhCollagen) and BioInk technology for 3D bioprinting of solid-organ scaffolds for human transplants, the companies said today, through a collaboration that could generate more than $44 million.

Through its wholly- owned organ manufacturing and transplantation-focused subsidiary Lung Biotechnology PBC, United Therapeutics has been granted what the companies termed an exclusive license “throughout the universe” by CollPlant to its technology for producing and using rhCollagen-based BioInk for 3D bioprinted lung transplants.

Lung Biotechnology PBC is a public benefit corporation formed to address the acute national shortage of transplantable lungs and other organs with a variety of technologies that either delay the need for such organs or expand the supply.