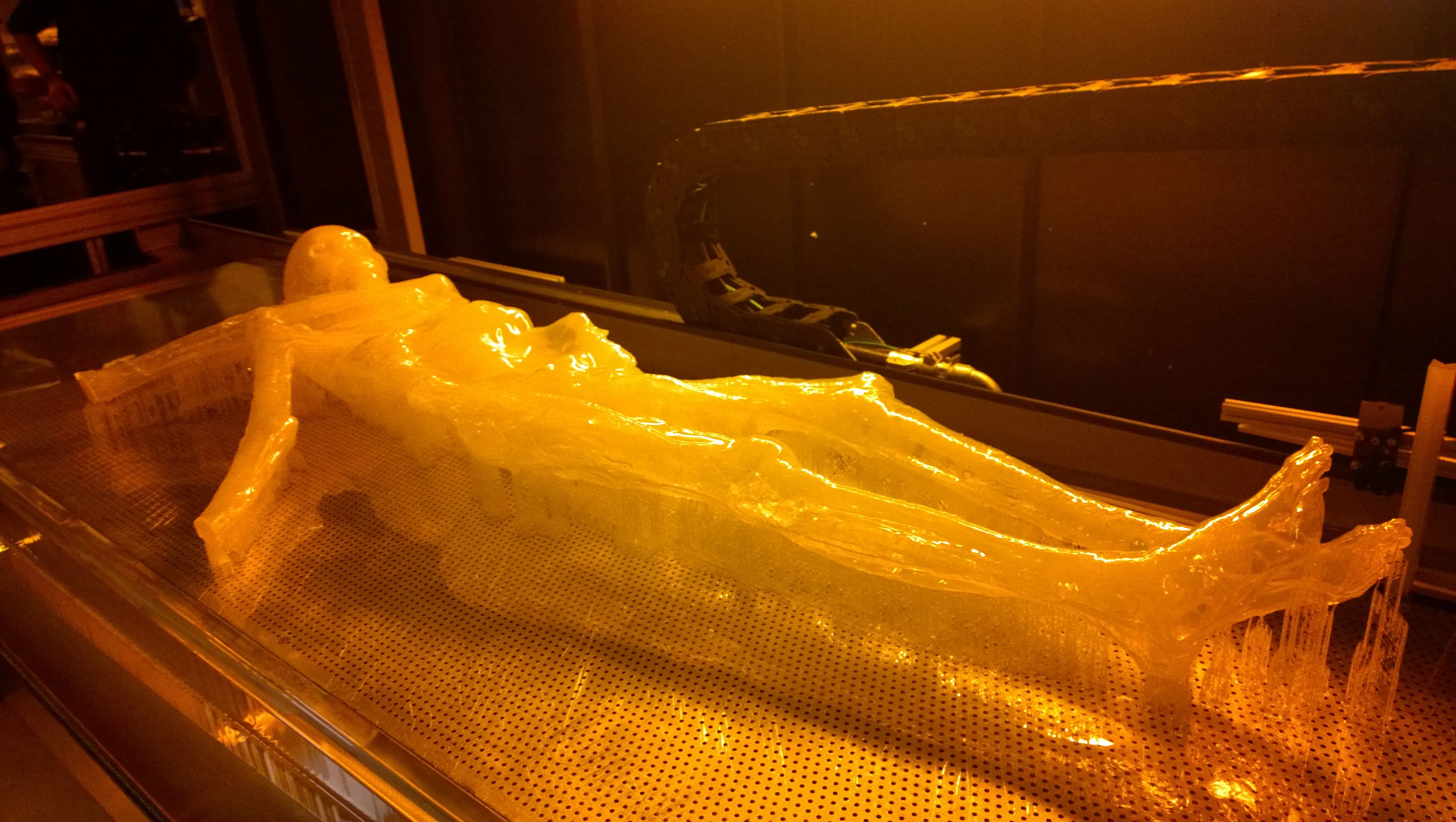

Using a sophisticated, custom-designed 3D printer, regenerative medicine scientists at Wake Forest Baptist Medical Center have proved that it is feasible to print living tissue structures to replace injured or diseased tissue in patients.

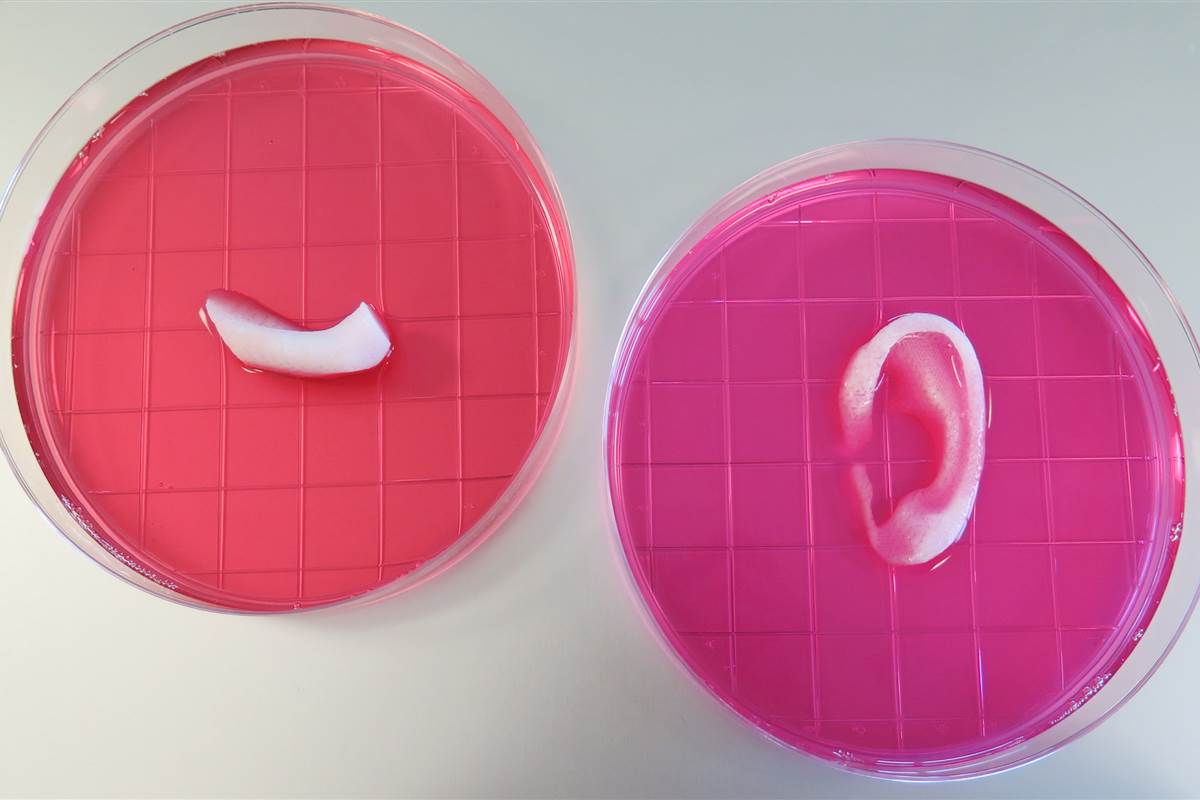

Reporting in Nature Biotechnology, the scientists said they printed ear, bone and muscle structures. When implanted in animals, the structures matured into functional tissue and developed a system of blood vessels. Most importantly, these early results indicate that the structures have the right size, strength and function for use in humans.

“This novel tissue and organ printer is an important advance in our quest to make replacement tissue for patients,” said Anthony Atala, M.D., director of the Wake Forest Institute for Regenerative Medicine (WFIRM) and senior author on the study. “It can fabricate stable, human-scale tissue of any shape. With further development, this technology could potentially be used to print living tissue and organ structures for surgical implantation.”